A temperature measurement method based on trivalent rare earth iron-based oxide as temperature sensing material

A technology of iron-based oxides and rare earth oxides, which is applied in the direction of physical/chemical changes in thermometers, thermometers, measuring devices, etc., can solve the problems of limited testing capabilities of infrared temperature measuring equipment, and achieve good measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

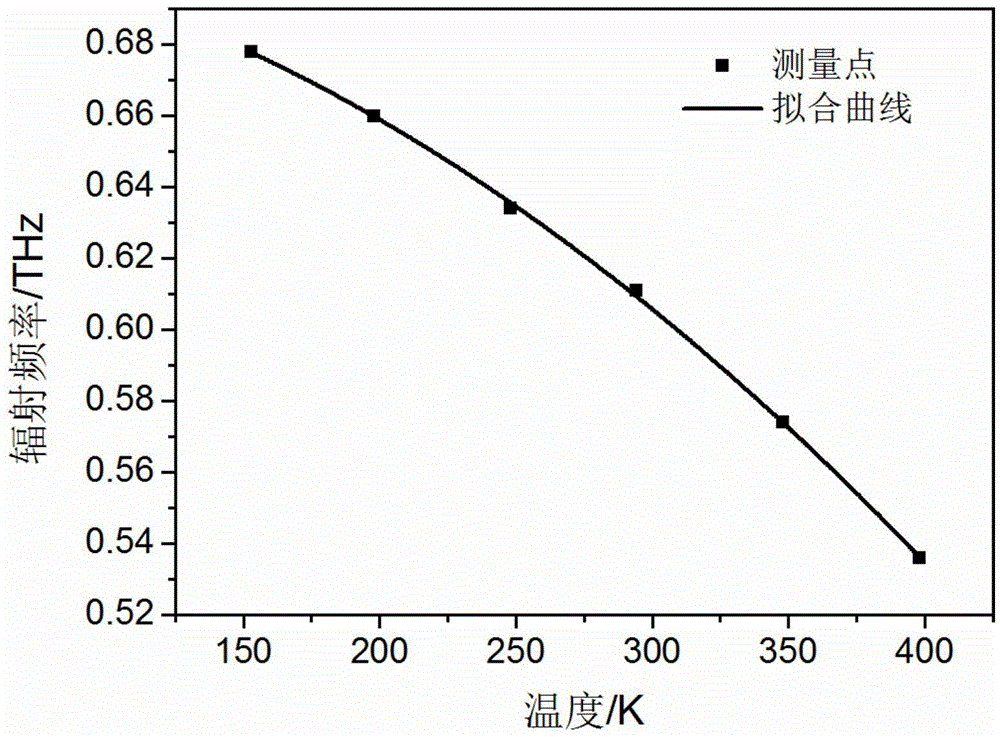

[0027] GdFeO 3 Belonging to the perovskite structure, it is an antiferromagnetic material below 661K, and its antiferromagnetic resonance frequency at room temperature is 0.61THz. Gadolinium oxide powder (Gd 2 o 3 ) and iron oxide powder (Fe 2 o 3 ) mixed at a molar ratio of 1:1, mechanically ball milled for 24-36 hours, and dried in an oven at 60-70°C to obtain a uniformly mixed powder; the product powder was heat-treated at 1100-1150°C for 2-3 hours to obtain a composition of GdFeO 3 The composite powder is made into a ceramic body with a diameter of 10-20mm and a thickness of 1-2mm by dry pressing technology; after 3-4 hours of pressureless sintering at 1350-1400°C, dense GdFeO 3 The ceramic material is the temperature sensing material; the GdFeO 3 The temperature sensing material is used as a test sample, and its magnetic dipole radiation frequency at different temperatures is tested on a terahertz time-domain spectrometer equipped with a temperature-variable accessor...

Embodiment 2

[0029] DyFeO 3 It also belongs to the perovskite structure, its antiferromagnetic-paramagnetic transition temperature is 645K, and its room temperature antiferromagnetic resonance frequency is 0.51THz. Dysprosium oxide powder (Dy 2 o 3 ) and iron oxide powder (Fe 2 o 3 ) mixed at a molar ratio of 1:1, mechanically ball milled for 36-48 hours, and dried in an oven at 70-80°C to obtain a uniformly mixed powder; the product powder was heat-treated at 1100-1150°C for 3-4 hours to obtain a composition of DyFeO 3 The composite powder is made into a ceramic body with a diameter of 10-20mm and a thickness of 1-2mm by dry pressing technology; after 1400-1450°C pressureless sintering for 2-3 hours, dense DyFeO 3 The ceramic material is the temperature sensing material; the DyFeO 3 The temperature sensing material is a test sample, and its magnetic dipole radiation frequency at different temperatures is tested on a terahertz time-domain spectrometer equipped with a variable temperat...

Embodiment 3

[0031] TmFeO 3 Belonging to the perovskite structure, it is an antiferromagnetic material below 632K, and its room temperature antiferromagnetic resonance frequency is 0.70THz. Gadolinium oxide powder (Tm 2 o 3 ) and iron oxide powder (Fe 2 o 3 ) mixed at a molar ratio of 1:1, mechanically ball milled for 36-48 hours, and dried in an oven at 60-70°C to obtain a uniformly mixed powder; the product powder was heat-treated at 1100-1150°C for 3-4 hours to obtain a composition of TmFeO 3 The composite powder is made into a ceramic green body with a diameter of 10-20mm and a thickness of 1-2mm by dry pressing technology; after 3-4 hours of pressureless sintering at 1400-1450°C, dense TmFeO 3 The ceramic material is the temperature sensing material; after measuring the radiation frequency-temperature standard curve, it can be used for temperature sensing devices.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com