A combustion subspace modeling and multi-objective optimization method and system for utility boilers

A multi-objective optimization, power plant boiler technology, applied in the field of power plant boiler optimization operation, can solve the problems of not considering unit load constraints, long model training time, long optimization time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

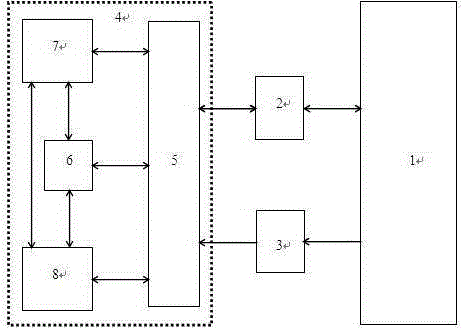

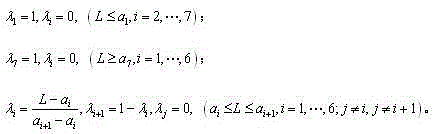

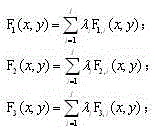

Image

Examples

Embodiment Construction

[0053] The following examples are used to illustrate implementation methods and steps of the present invention, but are not intended to limit the scope of the present invention.

[0054] The following describes a power plant boiler combustion subspace modeling and multi-objective optimization method for a 600MW coal-fired unit unit in combination with specific embodiments of the present invention. Specific steps are as follows:

[0055] 1. Determine the input variable z of the combustion optimization model. Specifically, it includes the low-level calorific value of the furnace coal, the volatile content of the furnace coal, the ash content of the furnace coal, the total moisture content of the furnace coal, the total coal volume of the furnace, the total air volume of the furnace, the opening of the secondary damper of each layer, and the burnout of each layer. Air door opening, bellows furnace differential pressure, flue gas oxygen content, coal feeder opening, coal mill ven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com