Metal ion carbonized adsorption material and preparation method thereof

A technology of adsorption materials and metal ions, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problem that polyethyleneimine cannot be recycled, and achieve high adsorption rate and good removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

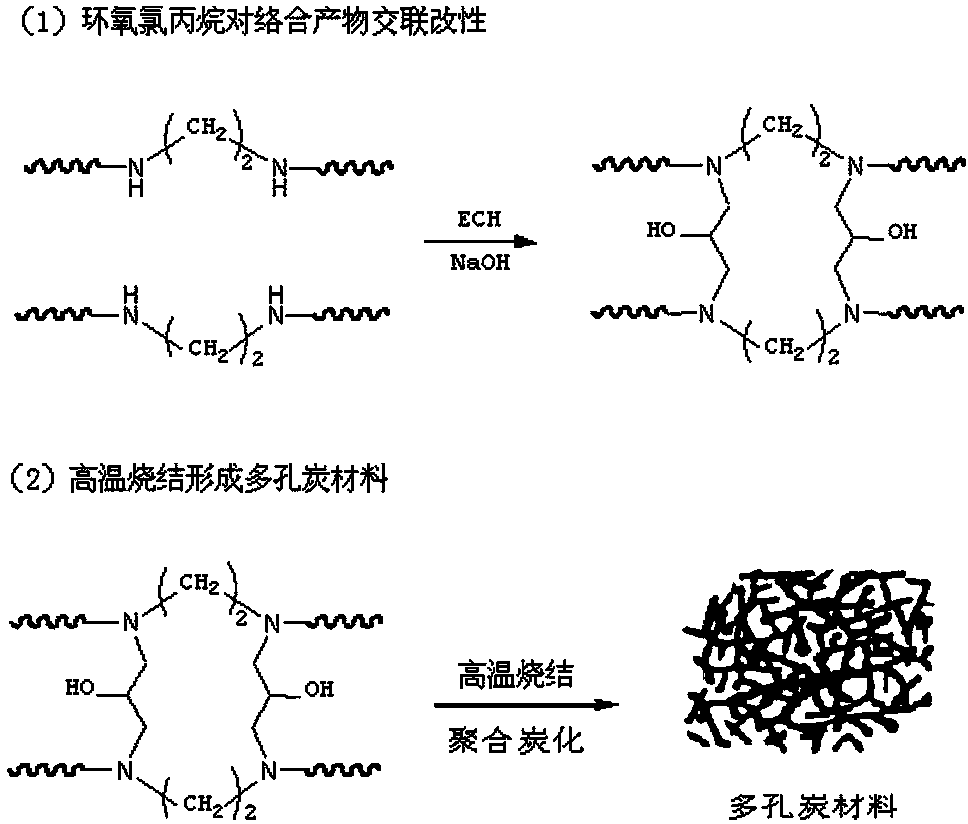

[0040] A preparation method of metal ion carbonization adsorption material, the steps are:

[0041] (1) Take 20g of 50% polyethyleneimine monomer solution, continue stirring to fully swell the system, add 12g of 50% epichlorohydrin ethanol solution dropwise at 30 °C, and adjust the system with 0.1mol / l sodium hydroxide solution The pH value reached 8, and the reaction was stirred for 1 h until the product became gelatinous, left standing for 3 h, suction filtered, the product was washed several times with ethanol, then repeatedly washed with distilled water, and vacuum dried to obtain the cross-linked modified polymer. Ethyleneimine;

[0042] (2) Take 5g of cross-linked modified polyethyleneimine and put it in the reaction kettle, put the reaction kettle in a closed carbonization furnace, and under nitrogen protection, the temperature is raised to 200 °C at a heating rate of 3 °C / min, and the temperature is kept constant for 2 hours. After natural cooling, take out, repeatedl...

Embodiment 2

[0048] A preparation method of metal ion carbonization adsorption material, the steps are:

[0049] (1) Take 20g of 40% polyethyleneimine monomer solution, keep stirring to fully swell the system, add 10g of 60% epichlorohydrin ethanol solution dropwise at 35°C, and adjust the system with 0.1mol / l sodium hydroxide solution The pH value of the product was reached to 7.5, and the reaction was stirred for 1.5h until the product became gelatinous, left standing for 2h, and suction filtered. The product was washed several times with ethanol, then repeatedly washed with distilled water, and vacuum-dried to obtain the cross-linking modification. Polyethyleneimine;

[0050] (2) Take 5g of cross-linked modified polyethyleneimine and put it in the reaction kettle, put the reaction kettle in a closed carbonization furnace, and under nitrogen protection, the temperature is raised to 300 °C at a heating rate of 4 °C / min, and the temperature is kept constant for 3 hours. After natural cool...

Embodiment 3

[0054] A preparation method of metal ion carbonization adsorption material, the steps are:

[0055] (1) Take 20g of 60% polyethyleneimine monomer solution, keep stirring to fully swell the system, add 11g of 40% epichlorohydrin ethanol solution dropwise at 40°C, and adjust the system with 0.1mol / l sodium hydroxide solution The pH value of the product was reached to 7, and the reaction was stirred for 2h until all the products became gelatinous, left standing for 2.5h, and suction filtered. The product was washed several times with ethanol, then repeatedly washed with distilled water, and dried in vacuum to obtain the cross-linking modification. Polyethyleneimine;

[0056] (2) Take 5g of cross-linked modified polyethyleneimine and put it in the reaction kettle, put the reaction kettle in a closed carbonization furnace, and under nitrogen protection, the temperature is raised to 250 °C at a heating rate of 5 °C / min, and the constant temperature is 2.5 hours. Take out after natu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bet specific surface area | aaaaa | aaaaa |

| Most probable aperture | aaaaa | aaaaa |

| Bet specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com