Vanadium pentoxide/titanium dioxide composite photocatalyst for degrading formaldehyde

A photocatalyst, photocatalytic technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

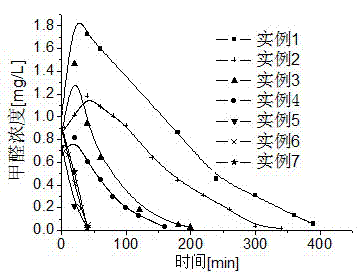

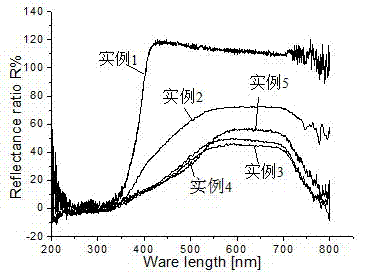

[0024] ν of Example 1 1 4.3×10 -3 mg / L / min, the ν of Example 2 2 3.8×10 -3 mg / L / min, ν of Example 3 3 4.5×10 -3 mg / L / min, ν of Example 4 4 6.8×10-3 mg / L / min, so: ν 4 > ν 3 > ν 2 > ν 1 , but in Examples 5 to 7, the photodegradation of formaldehyde becomes the main reason for the reduction of formaldehyde concentration before the temperature stabilizes (about 30 minutes), so the calculated rate does not match the actual situation, but by figure 1 It can be seen that the effects of these three examples on degrading formaldehyde are similar.

[0025] In the photocatalytic process, compounded V 2 o 5 The degradation rate of the P25 photocatalyst is larger than that of the uncomposited one. at V 2 o 5 / TiO 2 When the compounding ratio is very small, along with the increase of the compounding ratio, the degradation rate increases, and when the compounding ratio reaches 0.12 of embodiment 5, the degradation reaches the maximum, and the compounding reaches the best effe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com