Controllable fully biodegradable mulch film

A degradable mulch film and all-biological technology, applied in the field of controllable fully biodegradable mulch film, can solve the problems of short service life, airtightness, and difficulty in satisfying crops, etc., and achieve good performance and good anti-oxidative aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

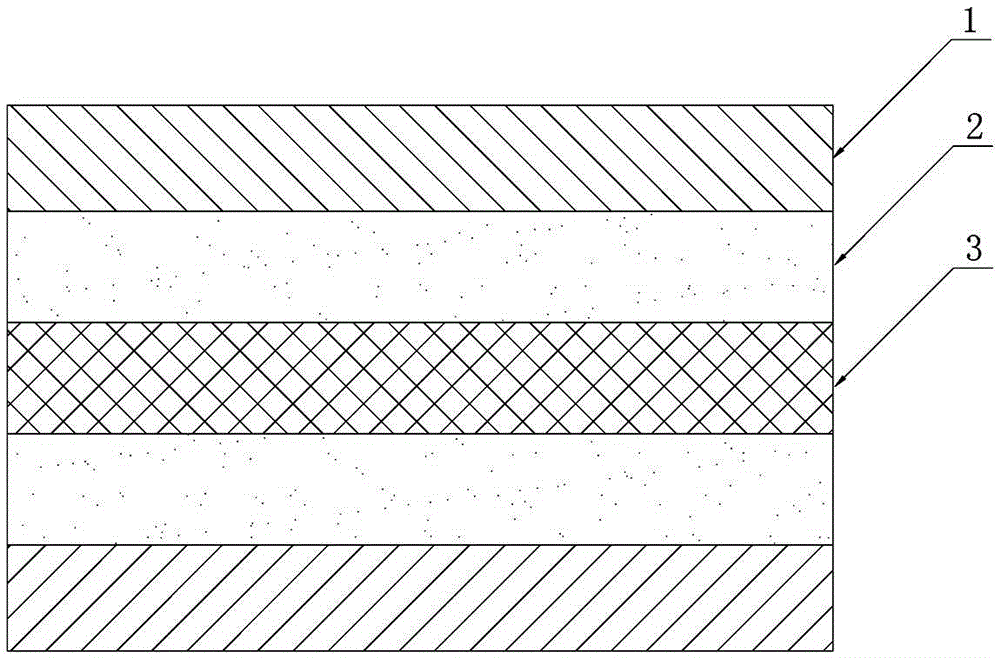

[0013] The controllable fully biodegradable mulch film is composed of an anti-degradation layer 1, an anti-aging layer 2, and an insulation layer 3, and is characterized in that an anti-aging layer 2 is provided on both sides of the insulation layer 3, and an anti-lysis layer 1 is provided outside the anti-aging layer 2.

[0014] The anti-hydrolysis layer 1 of the present invention is characterized in that the anti-hydrolysis layer 1 is arranged on the outside of the anti-aging layer, and the material of the anti-hydrolysis layer adopts 100 parts by weight of polybutylene succinate, 30 parts by weight of polyhydroxyl Alkanoate, 1 weight part of polycarbodiimide, 3 weight parts of superfine talcum powder, 0.2 weight part of erucamide.

[0015] The anti-aging layer 2 of the present invention is characterized in that the anti-aging layer 2 is arranged on the upper and lower sides of the insulation layer, and the material of the anti-aging layer adopts 100 parts by weight of butyle...

Embodiment 2

[0018] The controllable fully biodegradable mulch film is composed of an anti-degradation layer 1, an anti-aging layer 2, and an insulation layer 3, and is characterized in that an anti-aging layer 2 is provided on both sides of the insulation layer 3, and an anti-lysis layer 1 is provided outside the anti-aging layer 2.

[0019] The anti-hydrolysis layer 1 of the present invention is characterized in that the anti-hydrolysis layer 1 is arranged on the outside of the anti-aging layer, and the material of the anti-hydrolysis layer adopts 100 parts by weight of polybutylene succinate, 50 parts by weight of polyhydroxyl Alkanoate, 6 parts by weight of polycarbodiimide, 15 parts by weight of ultrafine talcum powder, and 1 part by weight of erucamide.

[0020] The anti-aging layer 2 of the present invention is characterized in that the anti-aging layer 2 is arranged on the upper and lower sides of the insulation layer, and the material of the anti-aging layer adopts 100 parts by wei...

Embodiment 3

[0023] The controllable fully biodegradable mulch film is composed of an anti-degradation layer 1, an anti-aging layer 2, and an insulation layer 3, and is characterized in that an anti-aging layer 2 is provided on both sides of the insulation layer 3, and an anti-lysis layer 1 is provided outside the anti-aging layer 2.

[0024] The anti-hydrolysis layer 1 of the present invention is characterized in that the anti-hydrolysis layer 1 is arranged on the outside of the anti-aging layer, and the material of the anti-hydrolysis layer adopts 100 parts by weight of polybutylene succinate, 40 parts by weight of polyhydroxyl Alkanoate, 4 parts by weight of polycarbodiimide, 7 parts by weight of ultrafine talcum powder, and 0.5 parts by weight of erucamide.

[0025] The anti-aging layer 2 of the present invention is characterized in that the anti-aging layer 2 is arranged on the upper and lower sides of the insulation layer, and the material of the anti-aging layer adopts 100 parts by w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com