Method for synthesis of CIASe (Cu-In-Al-Se) nanocrystalline by using triethylene tetramine auxiliary polyhydric alcohol solution

A technology of triethylenetetramine and copper indium aluminum selenium, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of difficult control of chemical components, unfavorable large-scale production, complicated operation, etc., and achieve product quality Phase stability, low cost, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

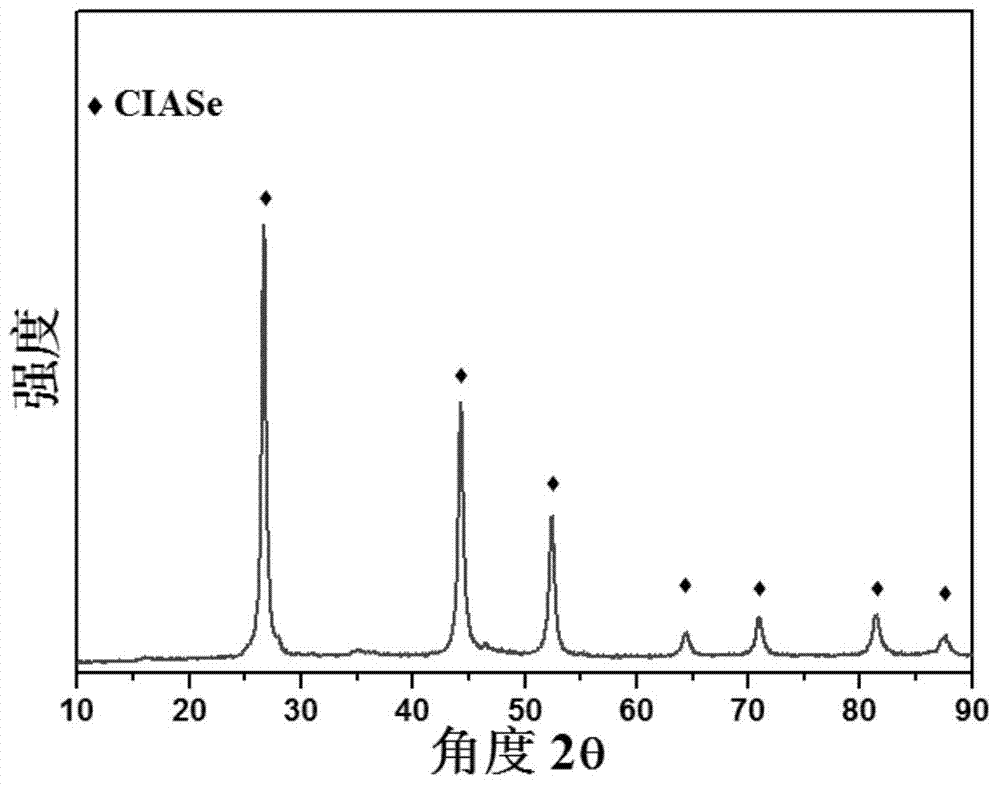

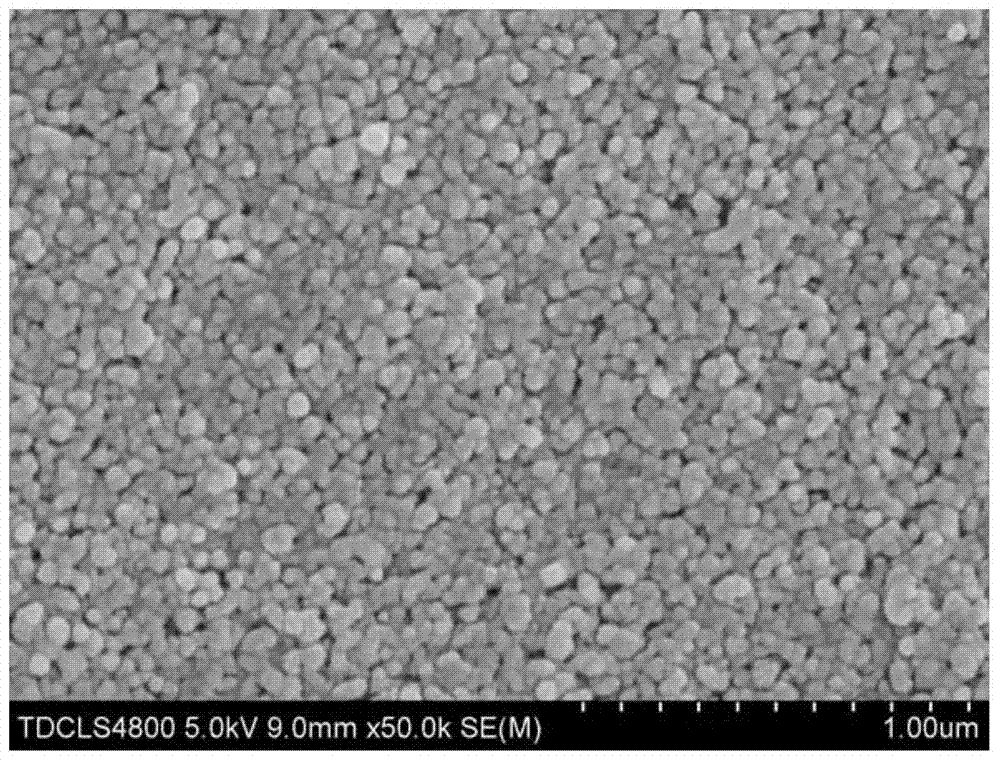

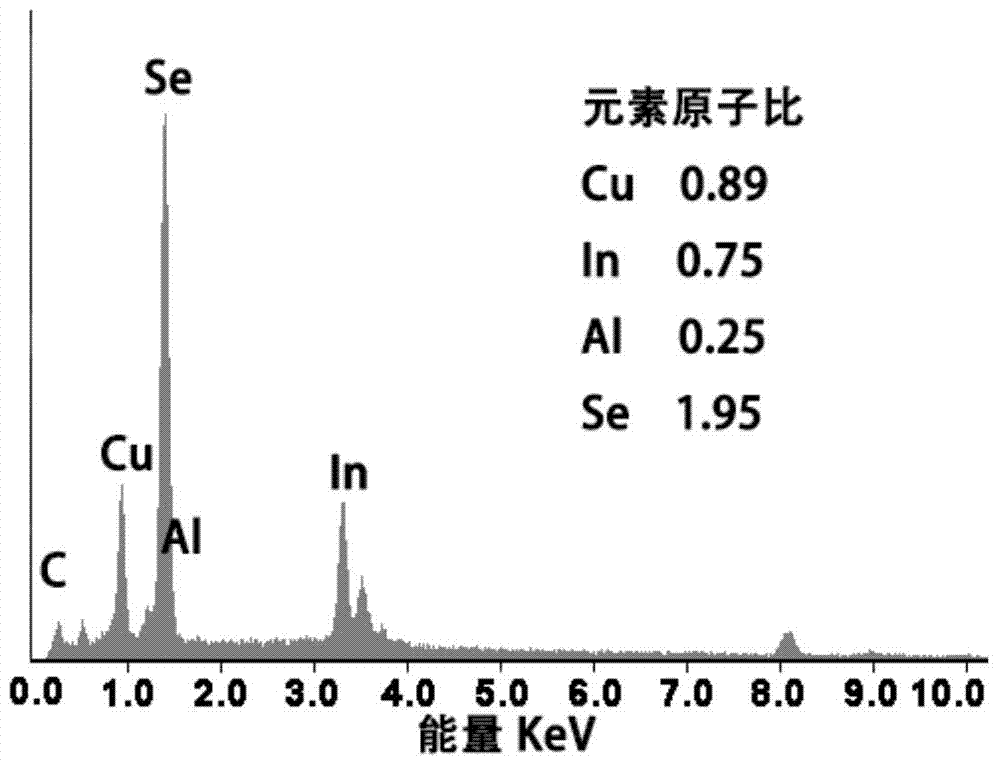

[0032] The process parameters of Examples 1-6 are injection temperature / reflux temperature. As can be seen from Table 2, when the injection temperature / reflux temperature of Example 1 was 170 / 170°C, the synthetic product phases were CISe, CuSe, Se, and no target CIASe phase was generated, and its stoichiometry and reaction solution Cu: The stoichiometry of In:Al:Se=1:0.75:0.25:2 is quite different. The phases of the synthesis products of Examples 2-4 are CIASe and Se. The synthetic products of Examples 5 and 6 are a single CIASe phase. The stoichiometric ratios of Examples 2-6 are all close to the stoichiometric ratio of the reaction solution Cu:In:Al:Se=1:0.75:0.25:2, and Example 6 is the best. As the temperature increases, the morphology of the synthesized products changes from sheet to granular, and the products of Examples 5 and 6 are granular. From the above analysis, it can be seen that for the parameters of injection temperature / reflow temperature, Example 6 is the o...

Embodiment 6

[0033] The technological parameter of embodiment 6~9 is that the addition amount of TETA is different. Wherein the synthetic product of embodiment 7 and 9 is the mixed phase of CIASe and Se, and embodiment 6 and 8 is the single phase of CIASe. From the results of the stoichiometric ratio of the synthesized products in Examples 6-9, the stoichiometric ratio of Example 6 is closest to the stoichiometric ratio of the reaction solution Cu:In:Al:Se=1:0.75:0.25:2. The morphology of the synthesized products is granular. As can be seen from the above analysis, for the TETA addition parameter, Example 6 is the optimum TETA addition, which is 3ml.

[0034]Examples 10-15 are the results of changing the In:Al molar ratio of the reaction solution under the optimal process parameters of Example 6, that is, Al / (In+Al) is 0, 0.1, 0.2, 0.3, 0.4, 0.5, respectively. It can be seen from Table 2 that Examples 11-13 are single CIASe phases, and other secondary phases exist. With the increase of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com