Preparation method of carbon fiber multi-scale reinforced composite component based on carbon nano-tube reinforcement

A technology for reinforcing composite materials and carbon nanotubes, which is applied in the field of composite material preparation, can solve the problems of low impact compression performance and interlayer shear strength, and achieve improved interface bonding force, increased shear strength, and compressive strength. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

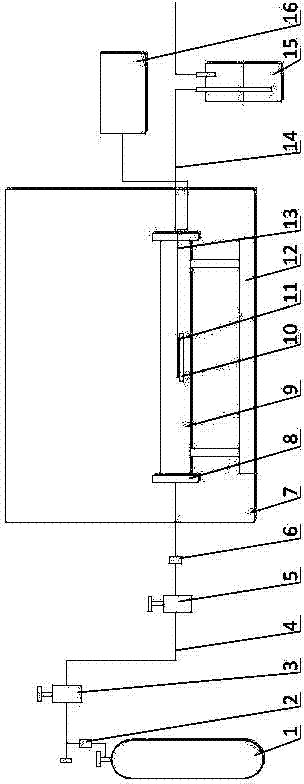

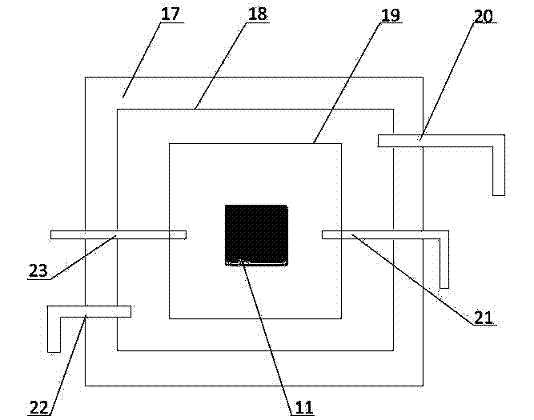

[0032]Put the carbon nanotube array or powder 11 obtained by chemical vapor deposition into the quartz tube 9 together with the substrate 10. Both ends of the quartz tube 9 are sealed with polytetrafluoroethylene or silica gel flanges 8, and this embodiment adopts silica gel flanges for sealing. Connect the two ends of the quartz tube 9 to the gas pipe, including the inlet pipe 4 and the exhaust pipe 14, and put them into the bracket 12 in the microwave resonance cavity 7 and fix them. Seal the microwave resonant cavity 7, connect one end of the inlet pipe 4 to the flowmeter 6, and connect the other end of the flowmeter to the precision flow regulating valve 5, and then connect the regulating valve 3, the pressure reducing valve 2 and the gas cylinder 1. The exhaust pipe 14 is connected to the filter 15. After the device is connected, open the regulating valves and flowmeters of the air intake pipeline, pass in a certain flow of inert gas, and exhaust the air in the pipe. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com