Evening primrose oil extraction method

An extraction method and grass oil technology, which are applied in the production of fat/fat and fat production, can solve the problems of difficult research, low oil yield, and difficult demulsification and separation of emulsions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

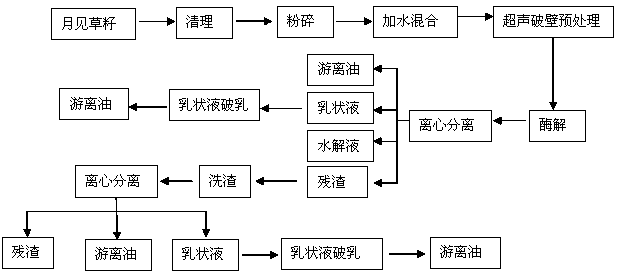

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Screening test for optimal parameters of evening primrose seed ultrasonic wall-breaking pretreatment

[0025] 1 Materials and methods

[0026] 1.1 Materials and reagents

[0027] Evening Primrose Seeds Jilin Province Wanshou Pine Nuts Food Company

[0028] Alcalase 2.4L Novozymes

[0029] 1.2 Main instruments and equipment

[0030] pHS-25 acidity meter Shanghai Weiye Instrument Factory

[0031] Electronic Analytical Balance Merlot-Toledo Instruments (Shanghai) Co., Ltd.

[0032] Centrifuge Beijing Medical Centrifuge Factory

[0033] Precision Electric Mixer Jiangsu Jintan City Ronghua Instrument Manufacturing Co., Ltd.

[0034] Electric constant temperature water bath Yuyao Dongfang Electrical Instrument Factory

[0035] Semi-automatic azotometer Shanghai Xinjia Electronics Co., Ltd.

[0036] Digester Shanghai Fiber Inspection Instrument Co., Ltd.

[0037] Hammer Mill China Tianjin Test Instrument Co., Ltd.

[0038] Soxhlet Extractor Tianjin Glass I...

Embodiment 2

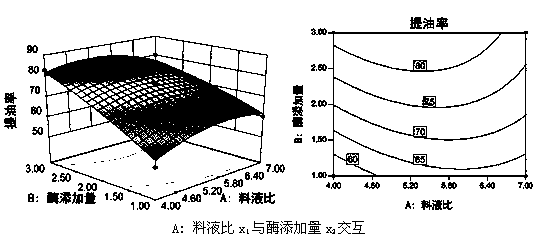

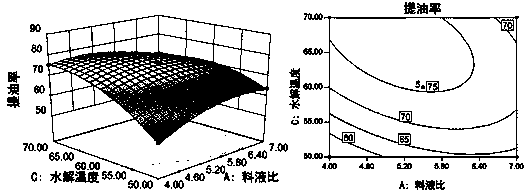

[0073] Example 2: Screening test for optimal parameters of enzymatic hydrolysis of evening primrose oil extracted by aqueous enzymatic method

[0074] Based on the best ultrasonic wall-breaking pretreatment determined in Example 1 to extract the technology of evening primrose oil, a single factor enzymolysis test is carried out to determine the enzymolysis process parameters (material-liquid ratio, enzyme addition, enzymolysis temperature, enzymolysis time) ) range. Taking the total oil extraction rate as the investigation index, a response surface design experiment with 4 factors and 3 levels was carried out.

[0075] 1 Materials and methods

[0076] 1.1 Materials and reagents

[0077] Evening Primrose Seeds Jilin Province Wanshou Pine Nuts Food Company

[0078] protex-6L alkaline endoprotease Danish novo company

[0079] 1.2 Main instruments and equipment

[0080] pHS-25 acidity meter Shanghai Weiye Instrument Factory

[0081] Electronic Analytical Balance Merlot-Toled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com