A two-stage anaerobic fermentation device and a method for producing methane by anaerobic fermentation using the device

A technology for anaerobic fermentation and methane production, applied in fermentation, biochemical equipment and methods, gas production bioreactors, etc. The effect of methane production, fast start-up, and improved operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

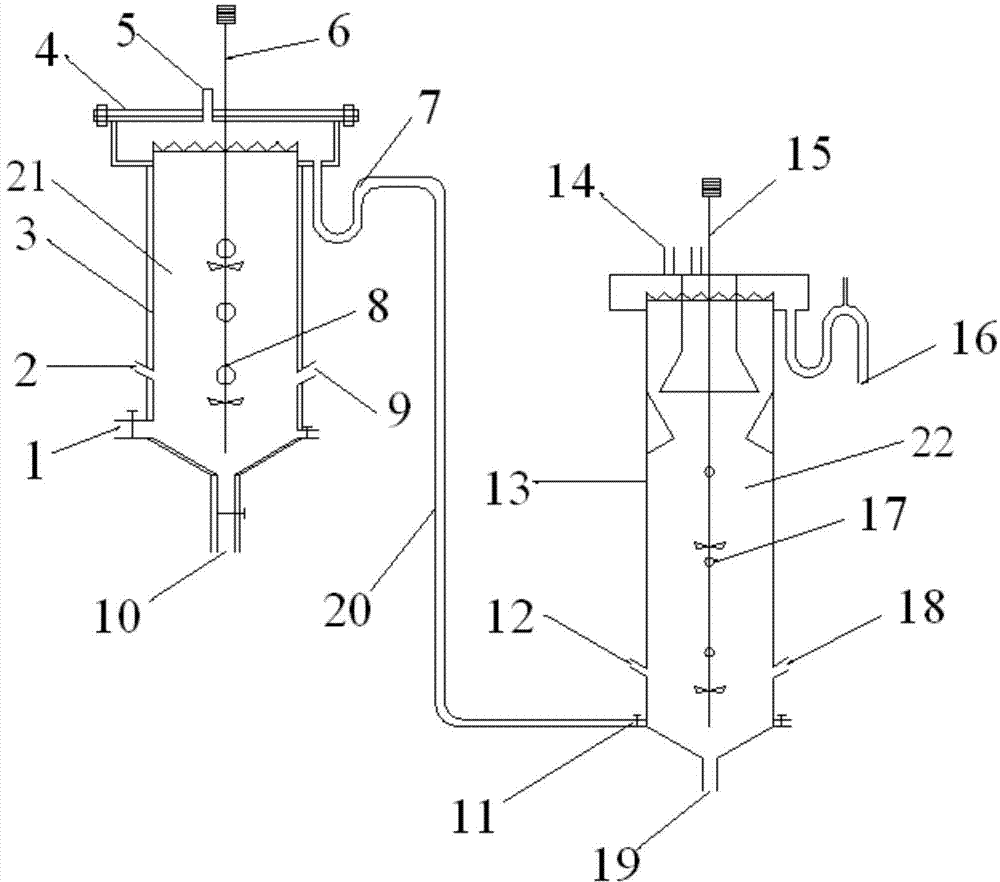

[0023] Embodiment 1: In this embodiment, a two-stage anaerobic fermentation device is composed of an acidogenic fermentation section and a methanogenic section, the acidogenic fermentation section is the acidogenic fermentation reactor 21, and the methanogenic section is the methanogenic reactor 22;

[0024] Wherein, the feed inlet A1 is arranged at the lower part of one side of the acidogenic fermentation reactor 21, the redox electrode A2 is arranged at the upper part of the feed inlet A1, and the upper part of the other side of the acidogenic fermentation reactor 21 is provided with a discharge The mouth A7 and the lower part are equipped with a temperature-controlled temperature probe A9, and a temperature-controlled winding resistance wire A3 is wound around the periphery of the acid-producing fermentation reactor 21. The top cover plate of the acid-producing fermentation reactor 21 is connected to the tank body by a flange 4, and The top of the acidogenic fermentation rea...

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the horizontal position of the discharge port A7 of the acidogenic fermentation reactor 21 is 20 cm higher than the horizontal position of the feed port B11 of the methanogenic reactor 22 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028]Specific embodiment three: Utilize a kind of two-stage anaerobic fermentation device described in specific embodiment one to carry out the method for anaerobic fermentation methane, specifically carry out according to the following steps:

[0029] 1. The mixture of cow dung and straw is used as the fermentation raw material of the acid-producing fermentation stage, and the biogas slurry is used as the inoculum of the acid-producing fermentation stage. Acid phase fermentation raw materials;

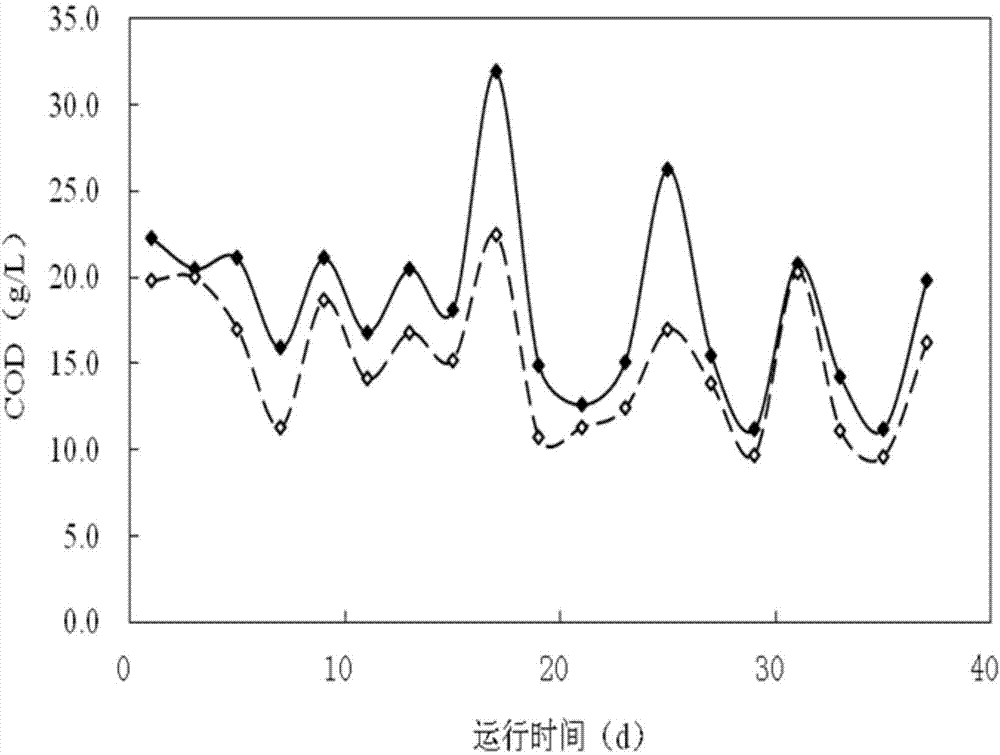

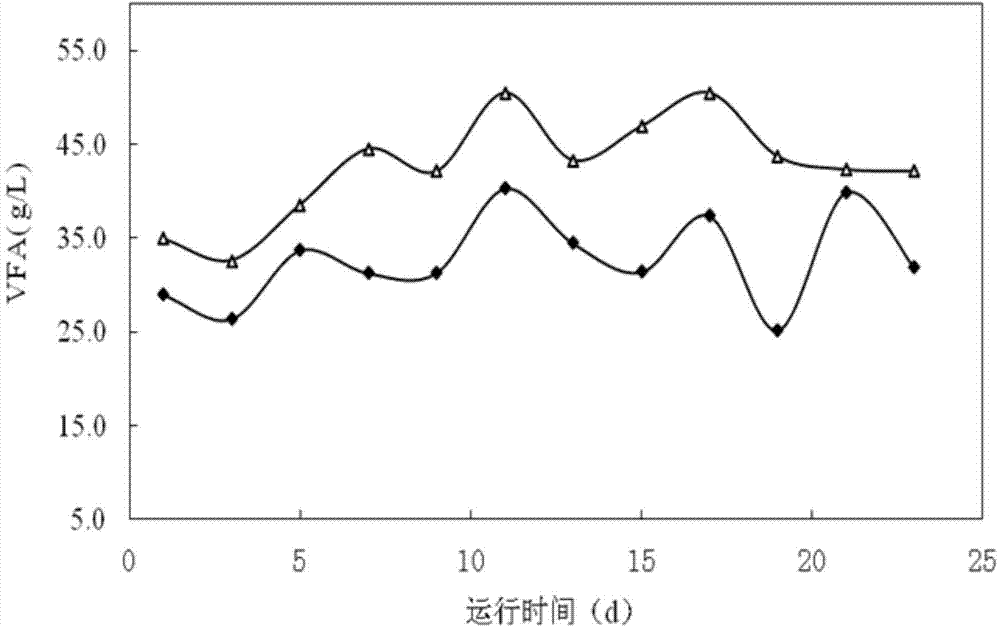

[0030] 2. Introduce nitrogen into the two-stage anaerobic fermentation device described in Embodiment 1 for more than 30 minutes, and simultaneously add the acid-producing phase obtained in step 1 into the acid-producing fermentation reactor 21 for medium-temperature acclimatization. When the acid-producing phase When the pH of the fermentation raw material is 6.2 and the volume content of acetic acid reaches more than 70%, the fermentation raw material is added to the acidogenic fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com