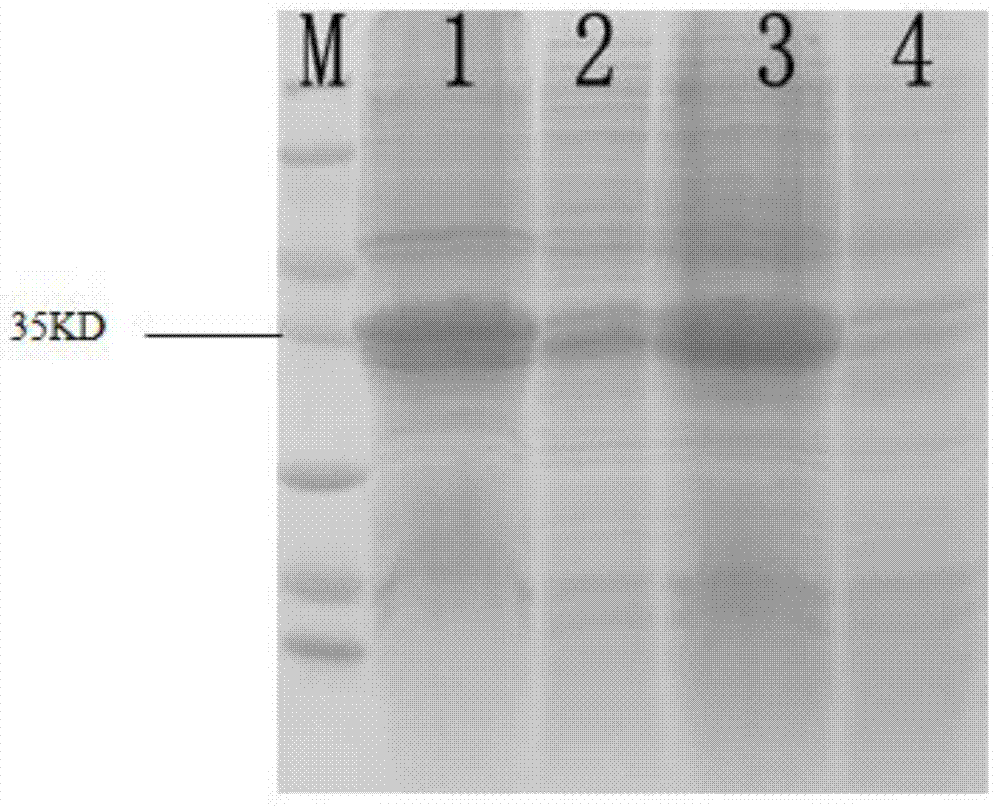

High density fermentation method of recombinant porcine interferon alpha 1 (rPoIFN alpha 1) gene engineering bacteria

A genetically engineered bacteria and high-density fermentation technology, applied in the field of fermentation process, can solve the problems of difficulty in meeting industrialization requirements, increasing renaturation steps, and low titer, avoiding the need for renaturation problems, efficient expression, shortening The effect of the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Seed fungus cultivation: inoculate the seed culture with the strains of the working seed fungus stored at --- 20°C, and use a rotary constant temperature and speed-adjustable shaker for cultivation; control the rotation speed at 220r / min, cultivate the temperature at 37°C, and the initial pH Value 7.1, culture time 10h;

[0033] (2) Fermentation: Put the cultured seed liquid into a 30L fermenter according to the inoculation amount of 1% for fermentation (the amount of fermentation medium is 20L), that is, pass sterile air into the fermenter with a ventilation rate of 1.5L / min to maintain The oxygen content in the fermentation tank is 10-20%, the culture temperature is set at 37°C, the mechanical stirring speed is 220r / min, and 3mol / L ammonia water is added to control the fermentation pH at 7.0-7.1;

[0034] (3) Feed: ferment for 2 to 3 hours, measure OD with UV spectrophotometer 600 After it is 0.4~1.0, add peptone 20~100g, yeast powder 10~40g, glucose 5~20g every ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com