Vacuum coating machine

The technology of a vacuum coating machine and a vacuum cover is applied in the field of machinery, which can solve the problems such as the decrease of the uniformity of the film on the surface of the coated workpiece, and achieve the effects of improving the heating condition, increasing the loading quantity, and increasing the loading quantity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

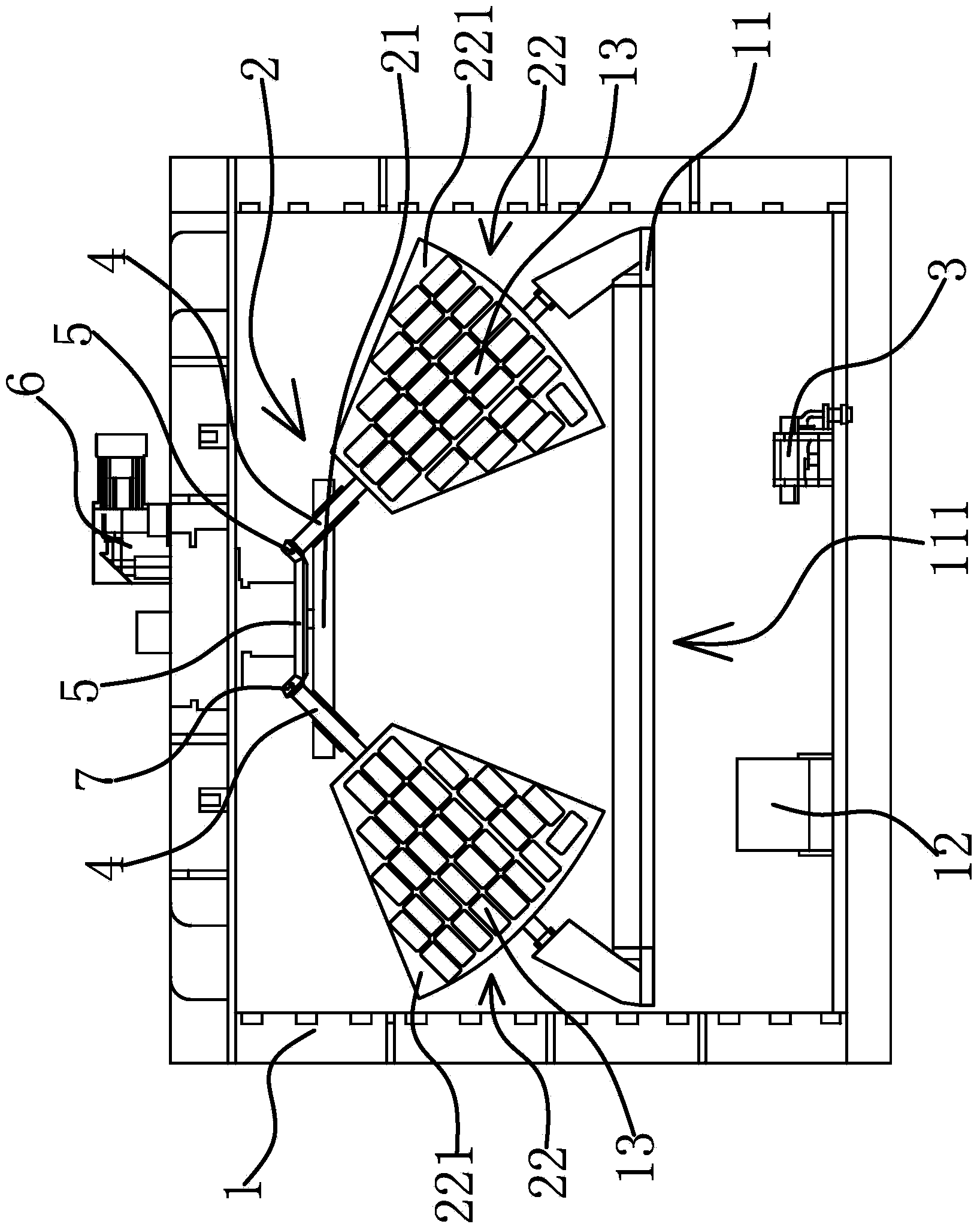

[0031] The vacuum coating machine includes a vacuum cover 1, a vacuum system, an umbrella stand 2, an evaporation source 3 and a driving mechanism.

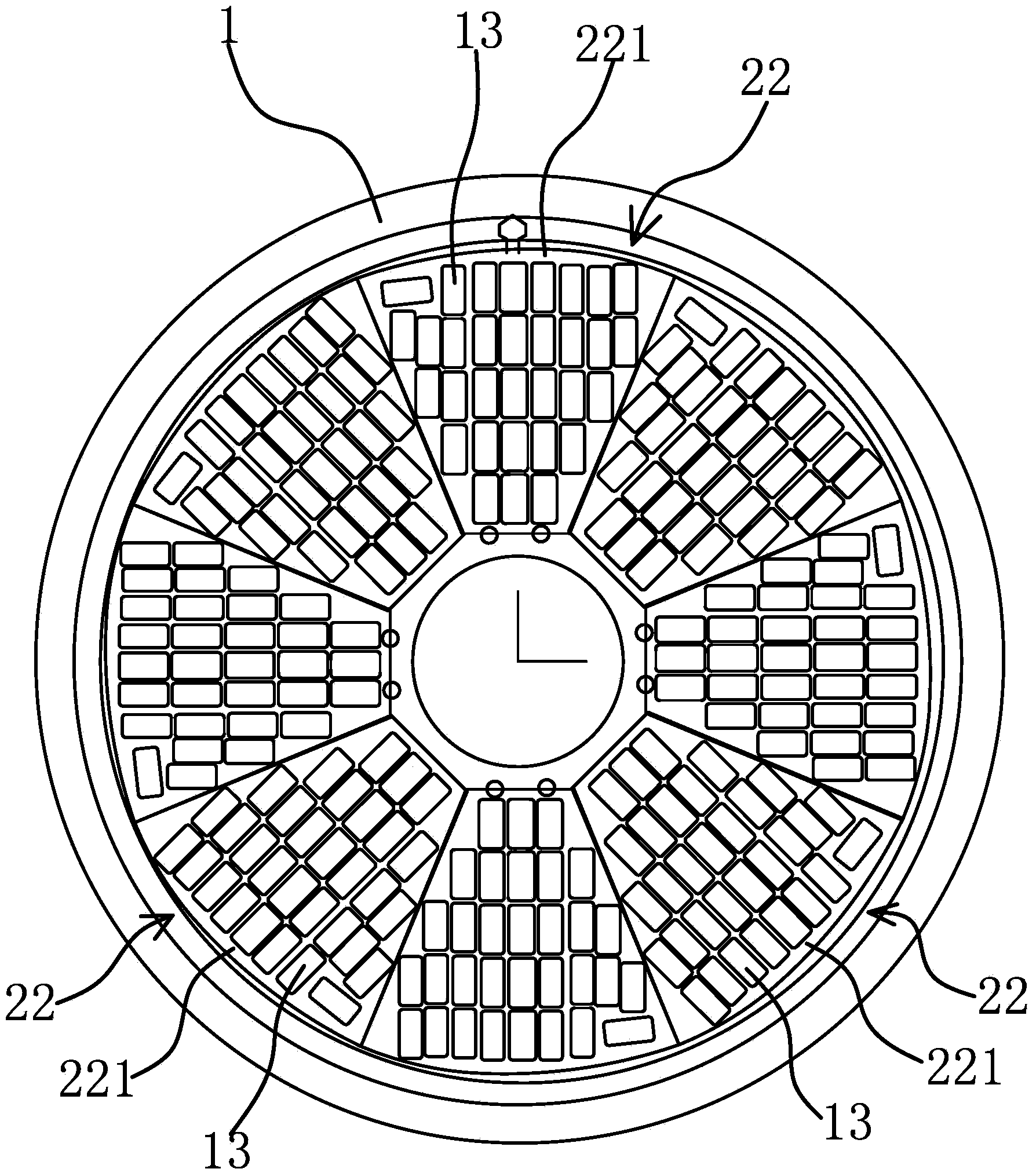

[0032] Specifically, as figure 1 As shown, the umbrella stand 2 includes a turntable 21 and a workpiece holder 22, the turntable 21 is connected with the vacuum cover 1 through a transmission shaft, and the transmission shaft can drive the rotating shaft to rotate in a circumferential direction. likefigure 1 and figure 2 As shown, the workpiece holder 22 is distributed in an umbrella shape along the circumferential direction of the turntable 21 , and the inclination angle of the workpiece holder 22 relative to the turntable 21 is less than 90°. A rotating shaft 4 is respectively fixed on the upper end of the workpiece holder 22, and the rotating disk 21 has mounting holes for the rotating shaft 4 to pass through, and the rotating shaft 4 is respectively packed into the corresponding mounting holes.

[0033] The driving mechani...

Embodiment 2

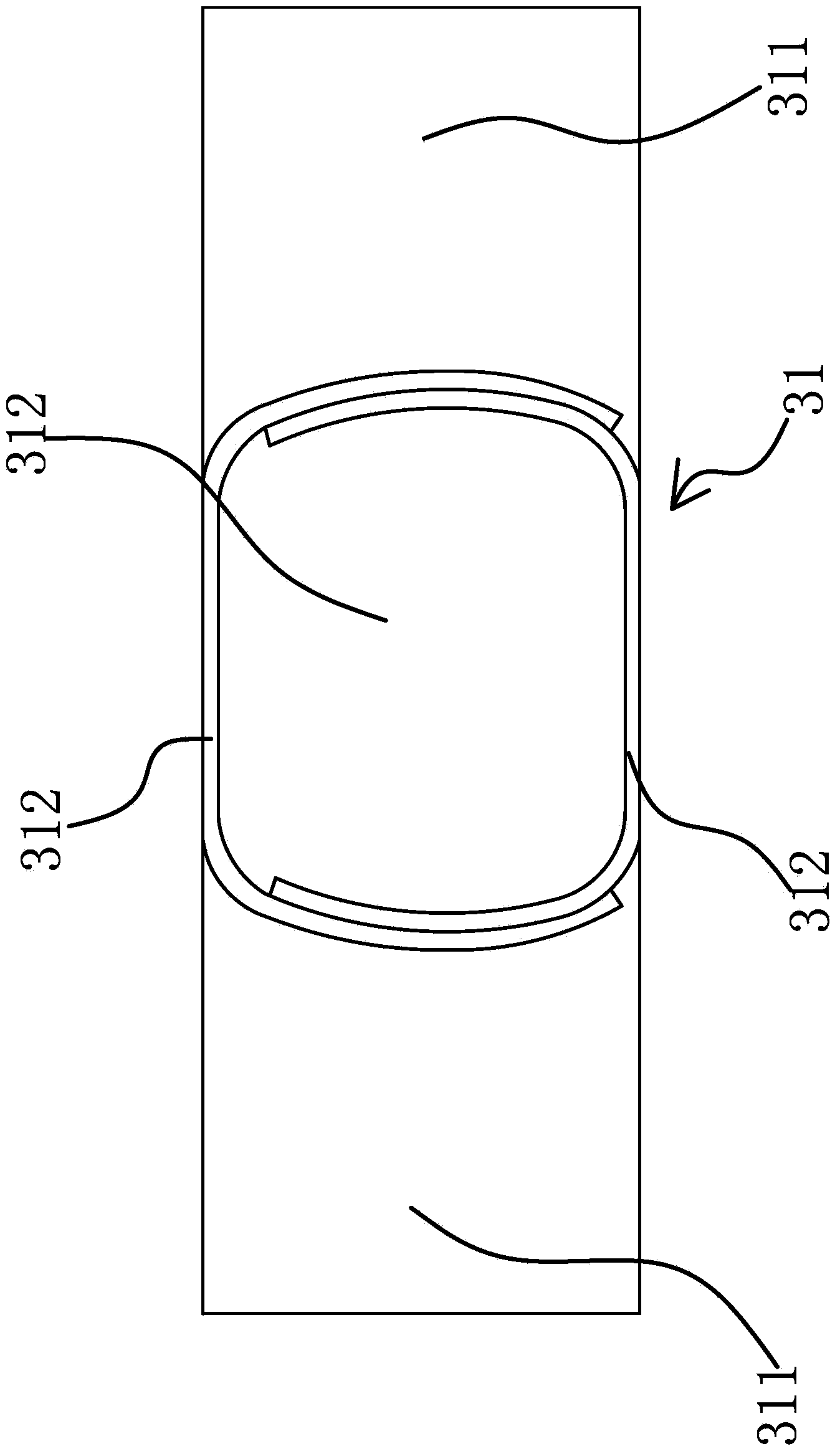

[0039] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that, as Figure 4 As shown, in the present embodiment, the drive mechanism includes a friction track 8 and a drive motor 6, the friction track 8 is circumferentially distributed on the inner wall of the vacuum cover 1, the drive motor 6 is connected to the turntable 21 through a transmission pair, and the other end of the workpiece holder 22 is provided with a Rotating shaft 1 4 centerline is located on the same straight line as rotating shaft 2 9, the end of rotating shaft 2 9 is fixedly connected with friction wheel 10, friction wheel 10 can roll in the friction track 8 to make the substrate rotate around the center line of rotating shaft 4 and rotating shaft 2 9 . During the rotation of the workpiece holder 22 with the turntable 21, the second shaft 9 moves circumferentially along the friction track 8, and the friction wheel 10 fixed on the se...

Embodiment 3

[0041] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1. The difference is that in this embodiment, the drive mechanism includes a rotation motor and a revolution motor, and the revolution motor is connected to the turntable 21 through a transmission pair, and the rotation motors are respectively Link to each other with rotating shaft one 4 through transmission pair. The autorotation motor and the revolution motor respectively drive the autorotation and revolution of the workpiece rack 22, and the precise control of the autorotation and revolution of the workpiece rack 22 can be realized through the automatic control equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com