Preparation method for anti-flaming polyurethane elastic fiber

A technology of polyurethane elasticity and polyurethane, which is applied in the manufacture of fire-resistant and flame-retardant filaments, the chemical characteristics of fibers, and the preparation of spinning solutions, etc., to achieve the effects of reducing breaking strength, reducing burning dripping, and excellent permanent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

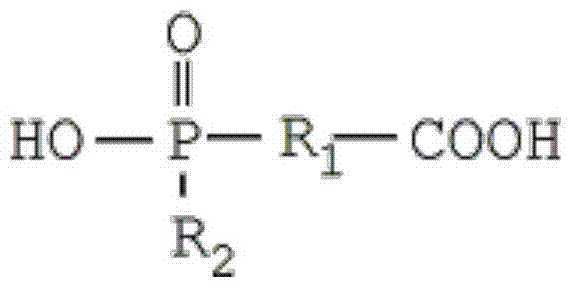

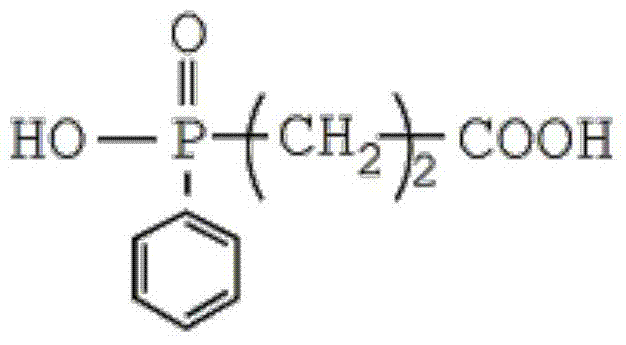

[0021] The invention guarantees permanent flame retardancy by copolymerizing with phosphorus-based flame retardants; further enhances flame retardancy by combining with a small amount of halogen-free phosphonate flame retardants, a small amount of melamine flame retardants and aluminum oxide and other flame retardant synergists The combination of copolymerization and blending ensures the spinnability of the spinning dope and effectively reduces the burning and dripping of the fiber. Its preparation method features include:

[0022] It is made through two main processes of preparing flame-retardant polyurethane spinning dope and subsequent dry spinning. Among them, the polyurethane spinning stock solution is a prepolymer formed by condensation and addition of polyether diol and diisocyanate; the prepolymer is formed by chain extension of a phosphorus-containing flame retardant, a diamine, and a chain terminator to form a main chain containing phosphorus elements. Flame-retarda...

Embodiment 1-3

[0053] The preparation of embodiment 1-3 experimental sample

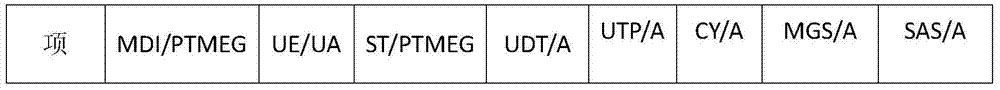

[0054] When preparing the samples of Examples 1-3, the experimental operation method was the same as that of the comparative sample, except that the chain extender with the ratio shown in Table 2 was used for chain extension.

[0055] Table 2 Experimental sample 1-3 chain extension solution material ratio data table

[0056]

[0057] Among them: 1) Number of moles: n UA +n UE +n CEPPA =n MDI -n PTMEG -n ST / 2

[0058] 2) A is the solid content of the polymer polymerized by RA2, that is, A is the sum of the mass of the following substances:

[0059] A=m PTMEG +m MDI +m UE +m UA +m CEPPA +m ST +m SPA

Embodiment 4-6

[0060] The preparation of embodiment 4-6 experimental sample

[0061] When preparing the samples of Examples 4-6, the experimental operation method is the same as that of Preparation Example 2, the difference is that, before the aging, the flame retardant of the proportion shown in Table 3 must be added to the D-FETK in addition, adding the flame retardant When using a flame retardant, first prepare the flame retardant and solvent DMAC into a solution with a mass concentration of 33.5% before adding.

[0062] Table 3 Experimental sample 4-6 Flame retardant addition data table

[0063]

[0064] Wherein: A is the solid content of the polymer polymerized by RA2, that is, A is the mass sum of the following substances:

[0065] A=m PTMEG +m MDI +m UE +m UA +m CEPPA +m ST +m SPA

[0066] Each embodiment polyurethane elastic fiber physical index is listed in table 4:

[0067] Table 4 each embodiment polyurethane elastic fiber physical index

[0068]

[0069] Among th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com