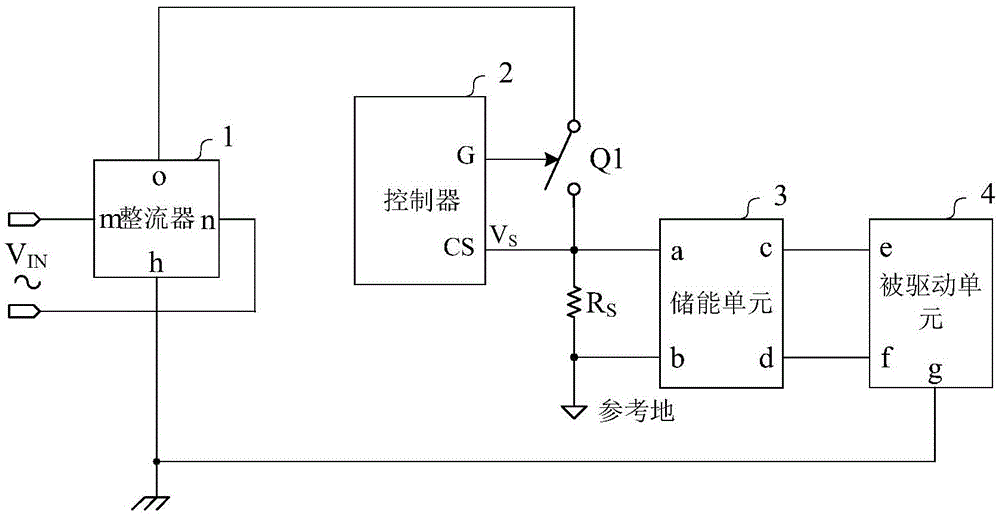

non-isolated led drive circuit

An LED drive and isolation technology, applied in the direction of electric lamp circuit layout, electric light source, lighting device, etc., can solve the problem that LED drive circuit cannot directly use triac dimmer, LED lamp service life limitation, application circuit design Complex problems, to achieve the effect of long service life, improve service life, reduce electromagnetic interference EMI

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

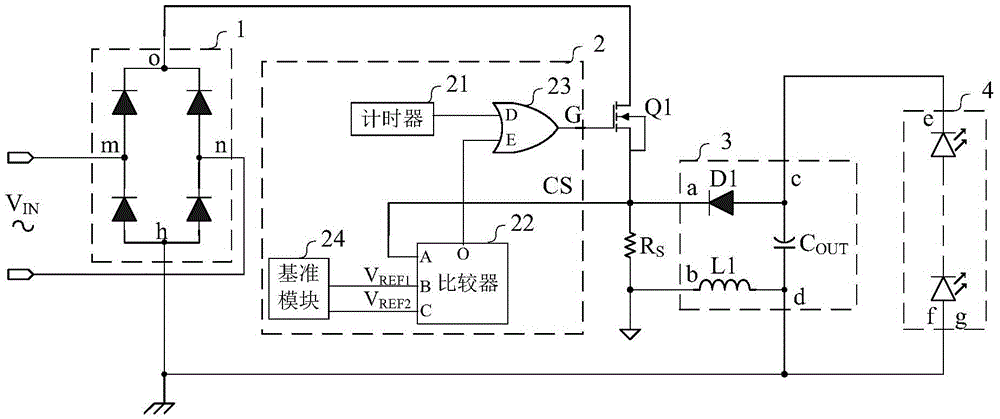

[0035] refer to figure 2 , the controller 2 of this example includes: a timer 21, a comparator 22, a logic gate 23 and a reference module 24; the energy storage unit 3 includes: a diode D1, an inductor L1 and a capacitor C OUT The driven unit 4 includes N LED lamps, N≥2; the rectifier bridge 1 adopts a traditional full-bridge rectification structure; the switching device Q1 adopts an N-type field effect transistor.

[0036] The connections of the components are as follows:

[0037] The output terminal o of the rectifier bridge 1 is connected to the drain of the N-type field effect transistor, the source of the N-type field effect transistor is connected to the input terminal a of the energy storage unit 3, and the sampling resistor R S Connected to the reference ground, the sampling resistor R S The voltage on the sampling signal V S .

[0038] The negative terminal of the diode D1 is used as the input terminal a of the energy storage unit 3, and its positive terminal is ...

Embodiment 2

[0047] refer to Figure 5 , the rectifier bridge 1 of the present example, the controller 2, the parts adopted by the energy storage unit 3 and the switching device Q1, and the connection relationship between the parts are all the same as in the embodiment 1; the driven unit 4 includes M LED lamps , M≥1.

[0048] The M LED lamps adopt a parallel connection structure; the positive terminals of the M LED lamps are connected to the output terminal d of the energy storage unit 3; the negative terminals are connected to the output terminal c of the energy storage unit 3; the positive terminals of the M LED lamps or The negative terminal can be used as the ground terminal g, and the negative terminal is selected as the ground terminal g in this example.

[0049] This example works as follows:

[0050] according to Figure 5 The working current flow direction of the given LED drive circuit. When the N-type field effect transistor was turned on, the timer 21 began counting, and th...

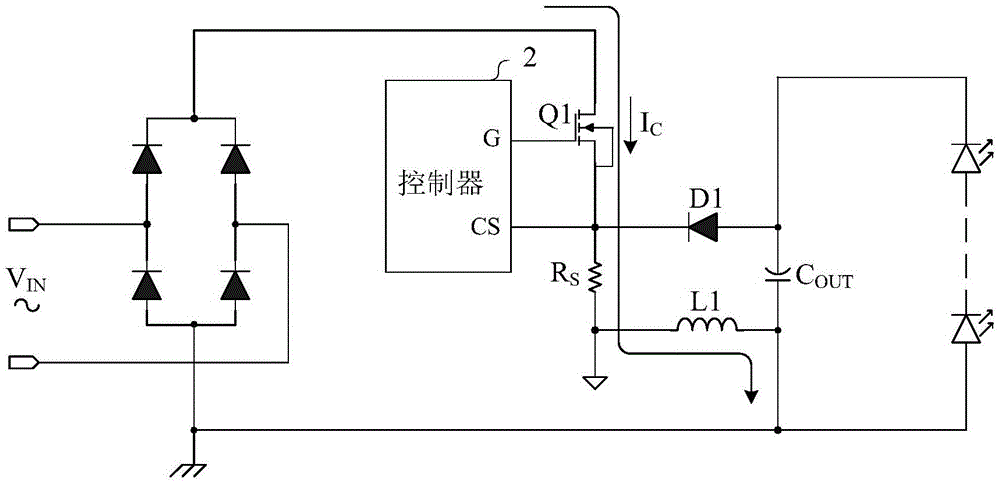

Embodiment 3

[0052] refer to Figure 6 , the rectifier bridge 1 of this example, the parts used by the controller 2 and the energy storage unit 3, and the connection relationship between the parts are all the same as in the embodiment 1; the driven unit 4 includes H LED lights, H≥3 ; Switching device Q1 adopts N-type triode.

[0053] The H LED lamps adopt a series-parallel connection structure, and the connection methods are various. The connection method selected in this example is: the H-1th LED lamp is connected in parallel with the H-th LED lamp, and then connected in series with the remaining H-2 LED lamps; The positive terminal of one LED lamp is connected to the output terminal d of the energy storage unit 3; the negative terminals of the H-1th LED lamp and the Hth LED lamp are connected to the output terminal c of the energy storage unit 3; the H LED lamps The positive or negative terminal of any one of the LED lamps can be used as the ground terminal g. In this example, the negat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com