Novel fish sauce processing method

A processing method, fish sauce technology, applied in multi-step food processing, food preparation, food science, etc., can solve the problems of low added value of products, waste of resources, pollution of marine and land environments, etc., to achieve full utilization and benefit environmental protection , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

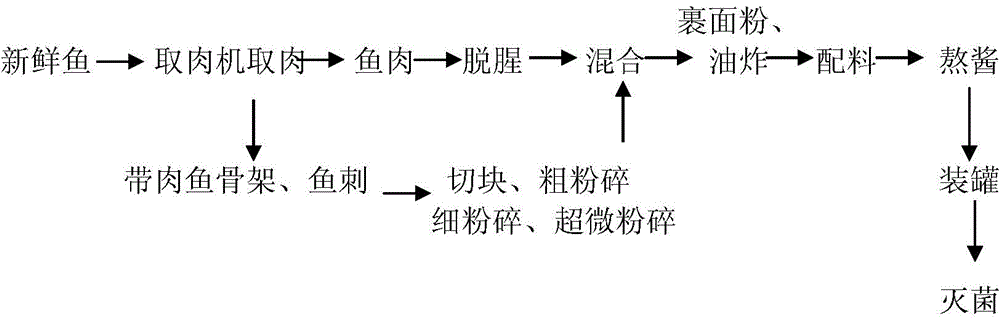

Method used

Image

Examples

Embodiment 1

[0032] 1. Clean fresh low-value fish or small-sized fish, remove the head, tail, and viscera, and put it into the meat extractor for meat.

[0033] 2. Remove the fish meat and soak in the deodorizing solution. The treatment solution is composed of water, salt (1%), citric acid (0.5%), and 50-degree white wine (0.7%). The soaking time is 100 minutes and the temperature is lower than 10°C.

[0034] 3. Cut the meaty fish skeleton and fishbone into small pieces (less than 2cm×2cm in size), freeze to below -20°C, pulverize to 20 mesh with a coarse grinder, add water, enter the colloid mill and crush to 80 mesh, and finally use Use a high-precision wet ultrafine pulverizer to pulverize to 100 mesh. At this time, the bone paste is a mixture of the bone and the attached meat on the skeleton, and the bone paste has a delicate taste and a smooth handle.

[0035] 4. After the meat is taken, the fish meat is not easy to shape, and it is even more difficult to shape after being mixed with...

Embodiment 2

[0039] 1. Clean fresh low-value fish or small-sized fish, remove the head, tail, and viscera, and put it into the meat extractor for meat.

[0040] 2. Remove the fish meat and soak in the deodorizing solution. The treatment solution is composed of water, salt (8%), citric acid (0.1%), and 50% white wine (0.1%). The soaking time is 10 minutes and the temperature is lower than 10°C.

[0041] 3. Cut the meaty fish skeleton and fishbone into small pieces (less than 2cm×2cm in size), freeze to below -20°C, pulverize to 20 mesh with a coarse grinder, add water, enter the colloid mill and crush to 80 mesh, and finally use Use a high-precision wet ultrafine pulverizer to pulverize to 100 mesh. At this time, the bone paste is a mixture of the bone and the attached meat on the skeleton, and the bone paste has a delicate taste and a smooth handle.

[0042] 4. After the meat is taken, the fish meat is not easy to shape, and it is even more difficult to shape after being mixed with bone p...

Embodiment 3

[0046] 1. Clean fresh low-value fish or small-sized fish, remove the head, tail, and viscera, and put them into the meat extractor for meat.

[0047] 2. Remove the fish meat and soak in the deodorizing solution. The treatment solution is composed of water, salt (5%), citric acid (0.2%), and 50-degree white wine (0.57%). The soaking time is 30 minutes and the temperature is lower than 10°C.

[0048] 3. Cut the meaty fish skeleton and fishbone into small pieces (less than 2cm×2cm in size), freeze to below -20°C, pulverize to 20 mesh with a coarse grinder, add water, enter the colloid mill and crush to 80 mesh, and finally use Use a high-precision wet ultrafine pulverizer to pulverize to 100 mesh. At this time, the bone paste is a mixture of the bone and the attached meat on the skeleton, and the bone paste has a delicate taste and a smooth handle.

[0049] 4. After the meat is taken, the fish meat is not easy to shape, and it is even more difficult to shape after being mixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com