Method for synthesis of metal telluride nanotubes

A metal telluride and synthesis method technology, applied in the chemical field, can solve the problems of poor operability, expensive instruments and equipment, and few successful synthesis cases, and achieve the effect of improving purity and reducing synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

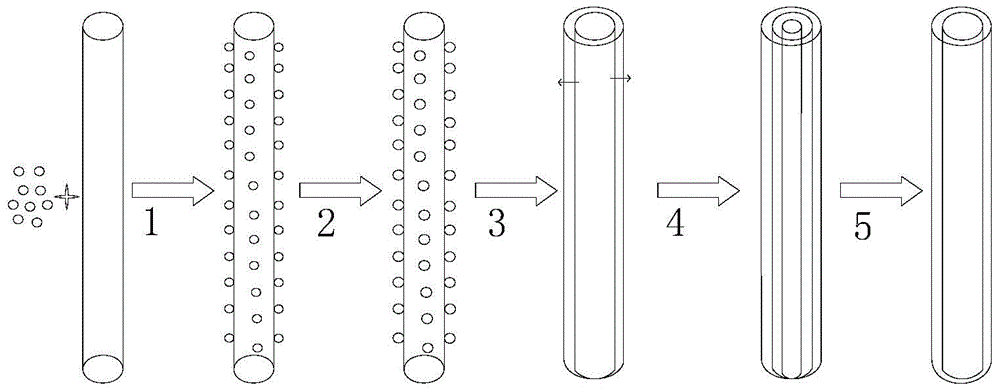

[0025] An embodiment of the present invention provides a method for synthesizing metal telluride nanotubes, including:

[0026] A. In a nitrogen atmosphere, heat a mixture of 2 milliliters of oleic acid and 2 milliliters of oleylamine to 150-250°C;

[0027] B. Maintain the temperature after heating in A, inject 0.2 ml of tellurium trioctylphosphine oxide extraction precursor within the first set time, and perform a chemical reaction within the second set time to obtain tellurium nanowires;

[0028] C. Cooling the solution in which the tellurium nanowires are located to 70-90° C., injecting 0.3 ml of bismuth or lead trioctylphosphine oxide extraction precursor and 0.3 ml of phenylhydrazine into the solution at the same time to obtain metal telluride;

[0029] D. After the temperature of C is stabilized, carry out a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com