A process for calcining phase-separated clinker with externally cast high-calcium granular slag

A granular, high-calcium technology, applied in the direction of cement production, etc., can solve the problems of less than 15% comprehensive utilization rate, large land occupation of metallurgical slag, soil and water environmental pollution, etc., to improve environmental pollution, stability and easy grinding Good performance and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

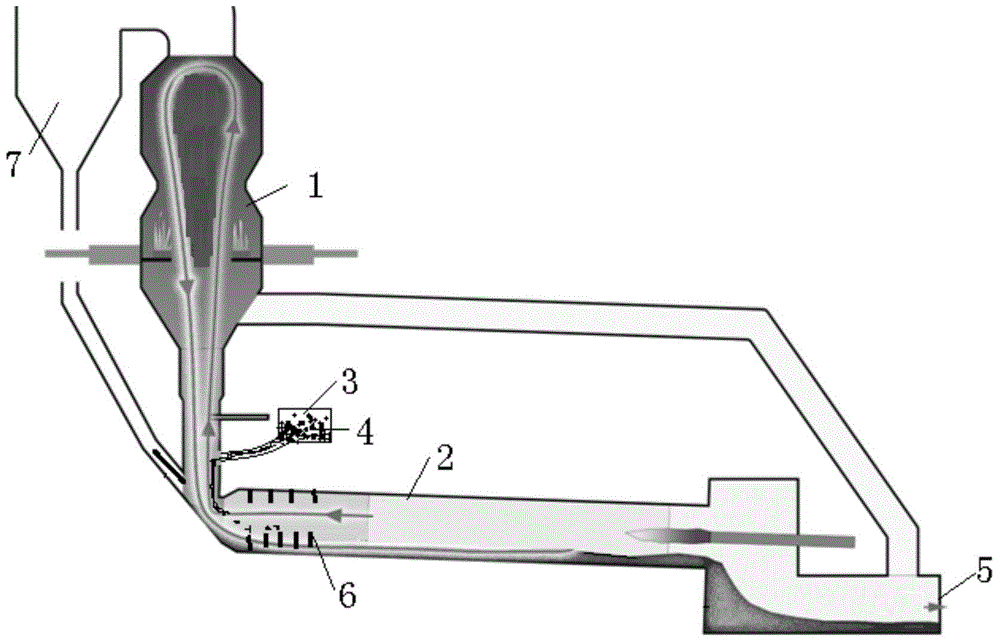

[0025] This embodiment provides a process for calcining phase-separated clinker with high-calcium granular slag (the device used in this process is shown in Figure 1), which includes the following steps:

[0026] 1) A feeder 3 is set between the precalciner 1 and the tail of the rotary kiln 2 of the new dry firing system to connect with the rotary kiln 2, and the feeder 3 throws the steel slag 4 continuously and evenly into the tail of the rotary kiln 2, The steel slag 4 is mixed with pre-decomposed cement raw meal, and the addition of the steel slag 4 is 5wt% of clinker output;

[0027] 2) After mixing, calcining is carried out in the rotary kiln 2, and the phase-separated clinker 5 mixed with the Portland cement clinker phase and heat treatment waste slag is fired. The calcination temperature is 1450° C., and the calcination time is 30 minutes.

[0028] It should be noted that the fine powder particles in the steel slag and the surface of the steel slag particles melt first ...

Embodiment 2

[0032] This embodiment provides a process for calcining phase-separated clinker with high-calcium granular slag, which includes the following steps:

[0033] 1) A feeder 3 is set between the precalciner 1 and the tail of the rotary kiln 2 of the new dry firing system to connect with the rotary kiln 2, and the feeder 3 throws the steel slag 4 continuously and evenly into the tail of the rotary kiln 2, The steel slag 4 is mixed with pre-decomposed cement raw meal, and the addition of the steel slag 4 is 15wt% of clinker output;

[0034] 2) After mixing, calcining is carried out in the rotary kiln 2, and the phase-separated clinker 5 mixed with Portland cement clinker phase and heat treatment waste slag is fired. The calcination temperature is 1435° C., and the calcination time is 60 minutes.

[0035] The f-CaO in the fired clinker is 0.76wt%, and the strength of the fired phase-separated clinker can reach 61.9MPa.

Embodiment 3

[0037] This embodiment provides a process for calcining phase-separated clinker with high-calcium granular slag, which includes the following steps:

[0038] 1) A feeder 3 is set between the precalciner 1 and the tail of the rotary kiln 2 of the new dry firing system to connect with the rotary kiln 2, and the feeder 3 throws the steel slag 4 continuously and evenly into the tail of the rotary kiln 2, The steel slag 4 is mixed with pre-decomposed cement raw meal, and the addition of the steel slag 4 is 30wt% of clinker output;

[0039] 2) After mixing, calcining is carried out in the rotary kiln 2, and the phase-separated clinker 5 mixed with Portland cement clinker phase and heat treatment waste slag is fired. The calcination temperature is 1435° C., and the calcination time is 60 minutes.

[0040] The f-CaO in the fired clinker is 0.82wt%, and the strength of the fired phase-separated clinker can reach 63.6MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com