Preparation method of wall body for modular building

A modular technology for construction, applied in the field of building materials, can solve problems such as threatening the health of animals and humans, affecting the appearance of objects, and damage to objects, and achieves excellent anti-mildew and flame-retardant properties, reduced density, and film-forming good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

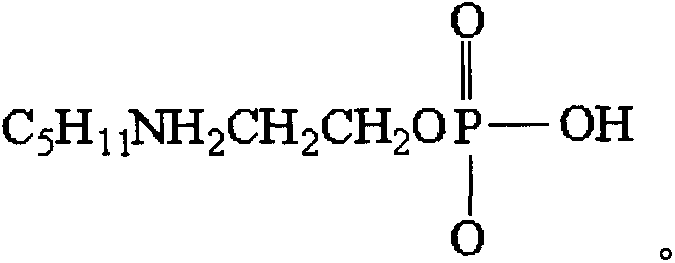

[0037] Synthesis Example - Synthesis of Phosphate Ester

[0038] Add 12mL bromo-n-pentane, 8ml diethanolamine, 30ml absolute ethanol and 4g potassium silanolate to the three-necked flask, reflux and stir for 3 hours, cool and filter to obtain the liquid; add 1.5ml of 85% phosphoric acid, 50ml Acetone and 2g of phosphorus pentoxide were heated to 60°C, stirred and reacted for 2 hours, and the acetone was distilled off to obtain a light yellow liquid, which was phosphoric acid ester.

[0039] The preparation of embodiment modular building body of wall

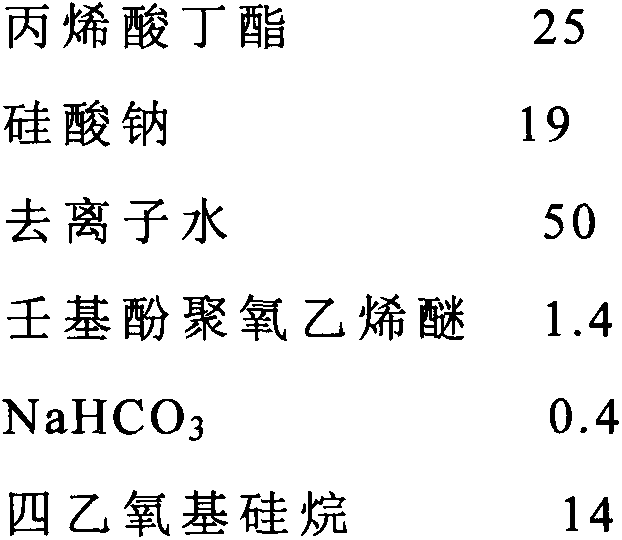

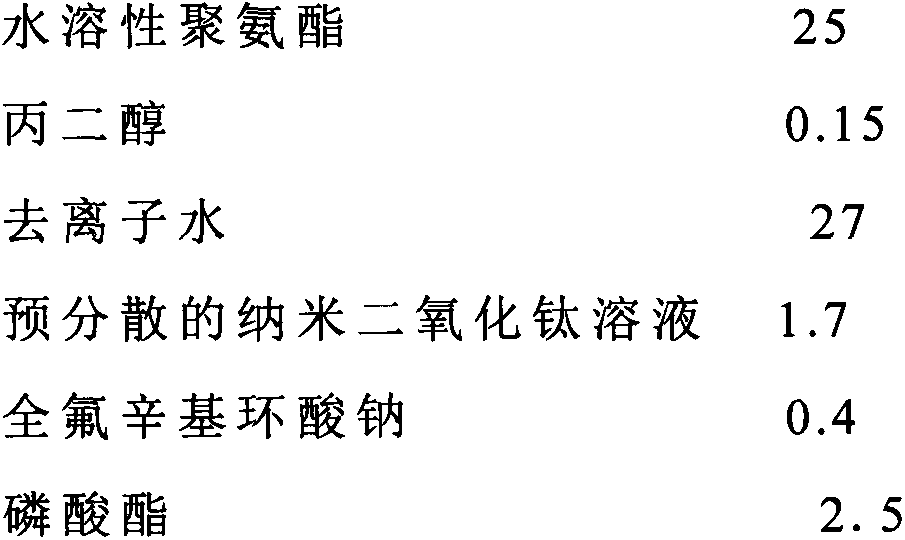

[0040] According to the ratio of raw materials in Table 1, the wall is prepared through the following steps:

[0041] (1) Mixing: Add cement and composite filler to water, stir for 30 minutes, then add hollow polymer microspheres, reinforcing fibers, sodium hypochlorite, and water reducer, and stir for 1.5 hours to obtain mixture A;

[0042] (2) Molding: Place steel grid frame and line pipe in the mold for preparing the wall bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com