Preparation method of functional telechelic polymer with controllable double-bond content of main chain

A technology of telechelic polymer and double bond content, which is applied in the field of preparation of functional telechelic polymer, which can solve the problems of insufficient heat resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

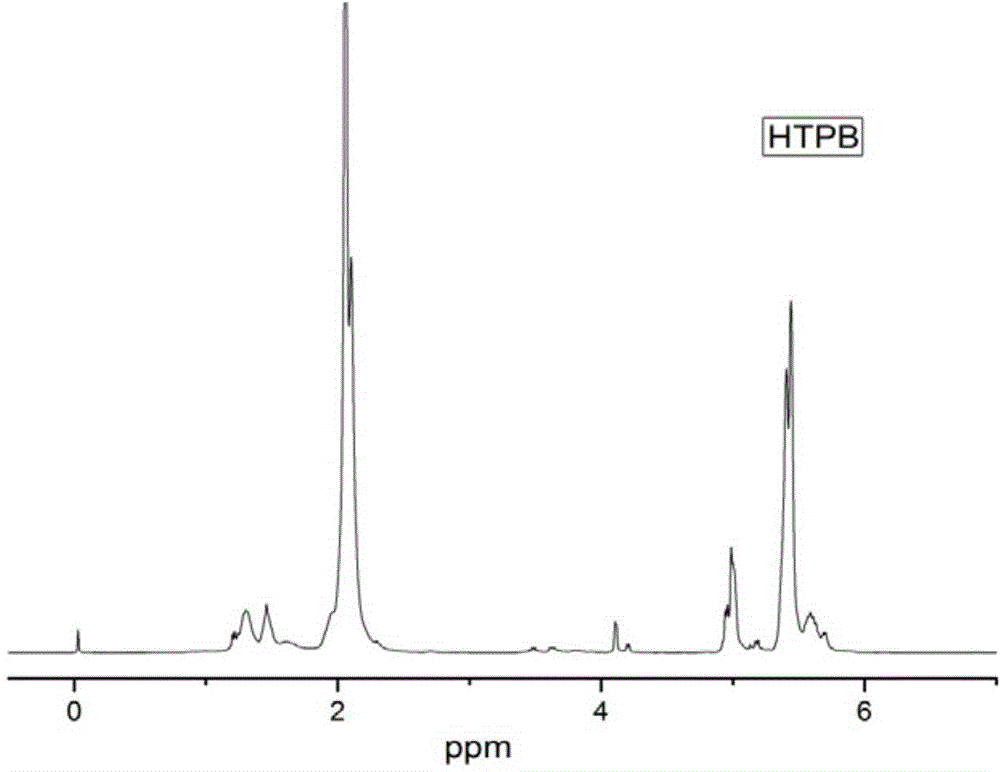

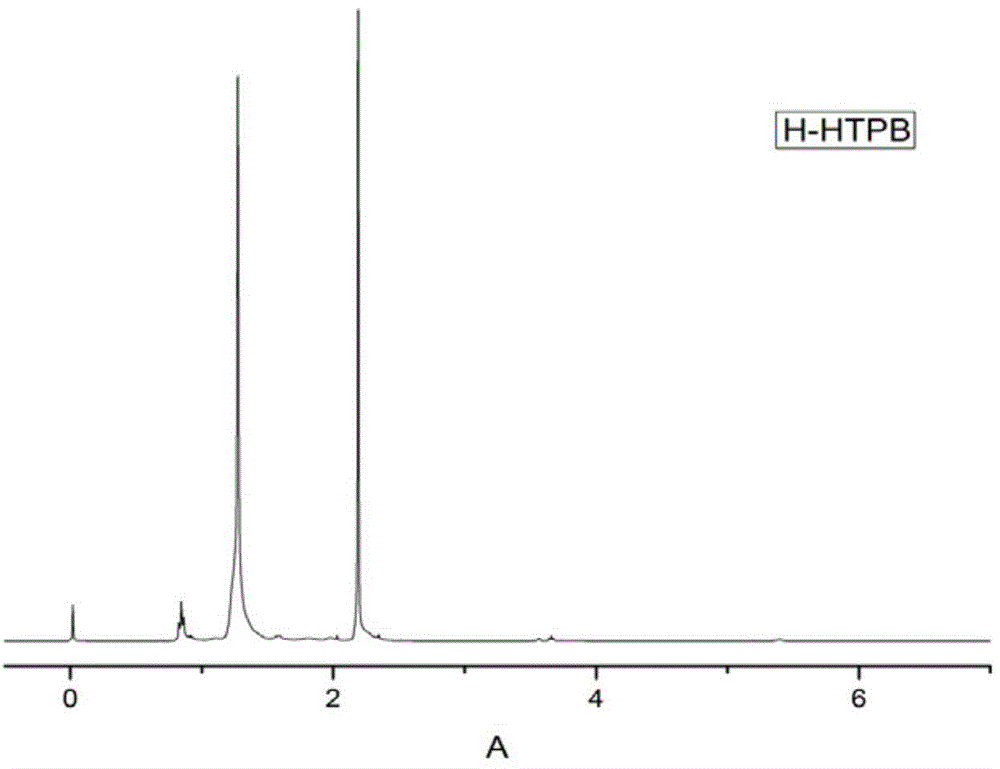

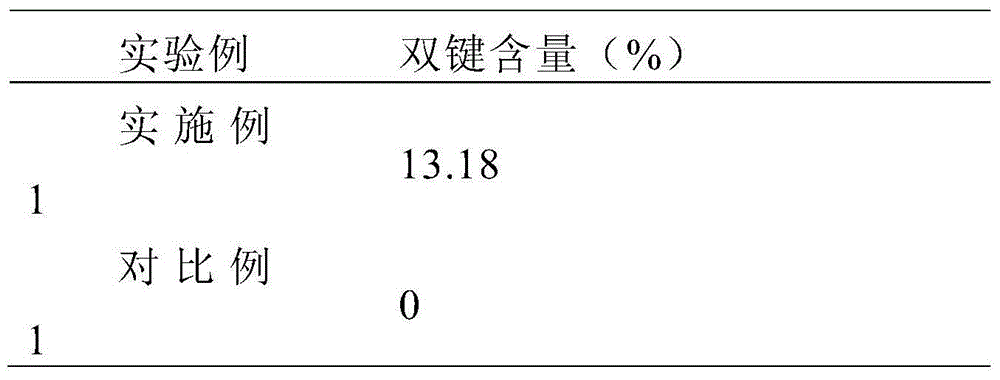

[0032] According to the above-mentioned general preparation steps, measure 60 ml of the pre-prepared hydroxyl-terminated polybutadiene xylene solution with a mass concentration of 12.5%, and add it into a 0.1 L reaction kettle. Add 0.06 g of triphenylphosphine rhodium chloride and three times the mass of triphenylphosphine, control the reaction temperature to 100°C, the hydrogen pressure to 2.5MPa, the reaction time to 6 hours, and the double bond content to 13.18%.

Embodiment 2

[0038] The triphenylphosphine rhodium chloride consumption in embodiment 1 is changed into 0.09g, the mass concentration of hydroxyl-terminated polybutadiene xylene solution is changed into 25%, 35%, 50%, other is the same as embodiment 1, the results see Table 2.

[0039] Table 2

[0040]

Embodiment 3

[0042] Change the triphenylphosphorus rhodium chloride consumption in embodiment 1 into 0.12g, 0.075g, 0.03g, other are with embodiment 1, and the results are shown in Table 3.

[0043] table 3

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com