Underwater high polymer adhesive and preparation method thereof

A technology of adhesives and polymers, applied in the field of high-performance reinforcement materials, can solve the problems of affecting the normal use of buildings, failure of reinforcement and reinforcement, hidden safety hazards, etc., to meet engineering bonding requirements and engineering service life , good durability, the effect of solving leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

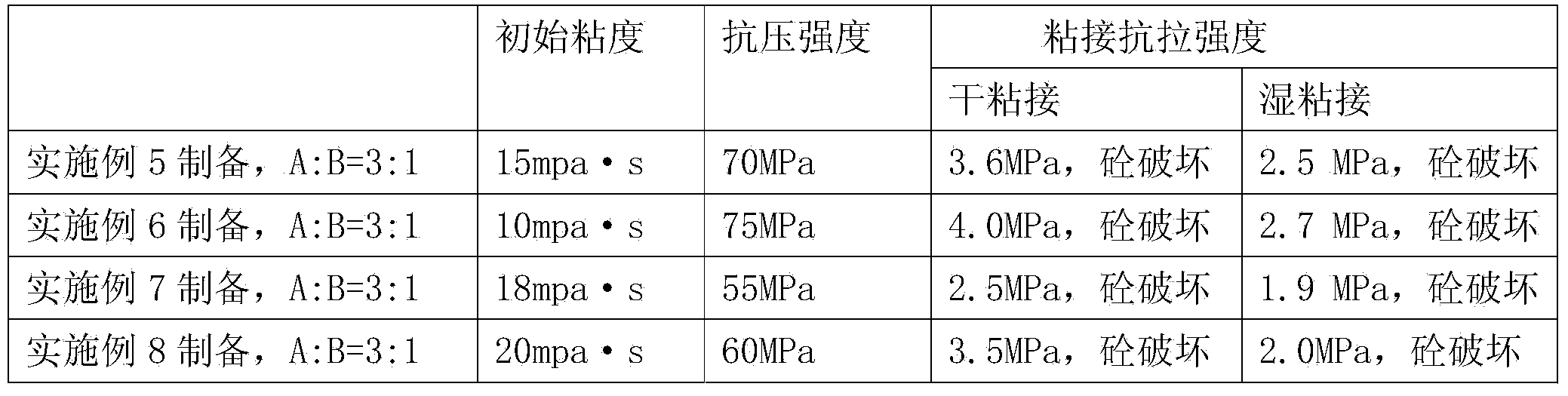

Examples

Embodiment 1

[0023] An underwater polymer adhesive, composed of component A and component B with a mass ratio of 3:1, component A is composed of the following components by weight: 90 parts of epoxy resin E44; polysulfide rubber JLY 0.5 parts of -121; 1 part of ethanol; 8 parts of acetone; 15 parts of butyl glycidyl ether; , 6, 7 parts of three (dimethylaminomethyl) phenol; 25 parts of modified ketimine.

Embodiment 2

[0025] An underwater polymer adhesive, composed of component A and component B with a mass ratio of 3:1, component A is composed of the following components by weight: epoxy resin E44 100 parts; polysulfide rubber JLY 1 part of -121; 0.8 parts of ethanol; 8 parts of acetone; 8 parts of butyl glycidyl ether; 15 parts of furfural; , 6, 10 parts of three (dimethylaminomethyl) phenol; 30 parts of modified ketimine.

Embodiment 3

[0027] An underwater polymer adhesive, composed of component A and component B with a mass ratio of 3:1, component A is composed of the following components by weight: 50 parts of epoxy resin E44; polysulfide rubber JLY 5 parts of -121; 0.5 parts of ethanol; 10 parts of acetone; 5 parts of butyl glycidyl ether; 20 parts of furfural; , 6, 8 parts of three (dimethylaminomethyl) phenol; 20 parts of modified ketimine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com