Composite low-temperature phase-change cold storage material

A cold storage material and low-temperature phase change technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of not easy to decompose, thermal performance attenuation, etc., and achieve easy operation, small supercooling degree, and appropriate phase change temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 6

[0021] Preparation and performance testing of cold storage materials in Examples 1 to 6

[0022] Weigh each raw material according to the weight percentage shown in Table 1, mix the weighed expanded graphite and n-hexanol with an ultrasonic oscillator, and cool to room temperature to obtain a composite low-temperature phase change cold storage material.

[0023] Each raw material weight percentage in table 1 embodiment 1~embodiment 6

[0024] raw material

Example 1

Example 2

Example 3

Example 4

Example 5

Example 6

expanded graphite

5%

5.2%

5.7%

6.1%

6.5%

7%

[0025] n-Hexanol

95%

94.8%

94.3%

93.9%

93.5%

93%

[0026] Performance tests were performed on the phase change cold storage materials prepared in Examples 1 to 6 in Table 1. Phase change latent heat adopts differential scanning calorimetry (DSC), test conditions: 1) purge gas and flow rate: high-purity nitrogen...

Embodiment 7

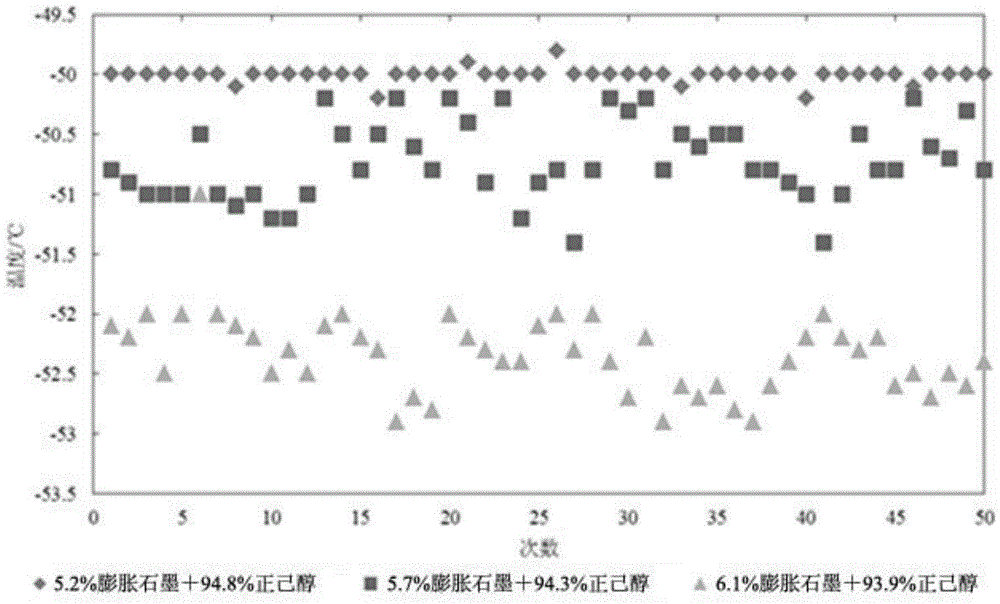

[0029] Example 7 Cyclic charging / discharging performance test of cold storage material

[0030] Prepare three cold storage materials, namely 5.2% expanded graphite + 94.8% n-hexanol, 5.7% expanded graphite + 94.3% n-hexanol, 6.1% expanded graphite + 93.9% n-hexanol, and charge the three cold storage materials 50 times Cold and cooling experiments, see the results figure 1 . From figure 1 It can be seen from the figure that the cycle charging and cooling performance of the three phase change cold storage materials are relatively good, and the fluctuation range of the phase change temperature is relatively fixed. After 50 times of cooling and cooling experiments, the 5.2% expanded graphite + 94.8% n-hexanol and 5.7% expanded graphite + 94.3% n-hexanol cold storage materials appeared solid-liquid separation phenomenon, and the 6.1% expanded graphite + 93.9% n-hexanol There is no solid-liquid separation phenomenon in the cold storage material, indicating that the expanded graph...

Embodiment 85

[0031] Example 85.7% expanded graphite + 94.3% n-hexanol phase change cold storage material characteristic analysis

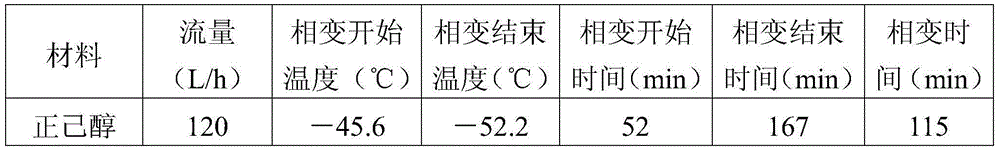

[0032] Through the cooling and cooling experiments of n-hexanol, 5.7% expanded graphite + 94.3% n-hexanol phase change cold storage materials, their phase change start temperature, phase change end temperature, and phase change time can be obtained. The results are shown in Table 3.

[0033] Table 3 Phase change temperature and cold charging time of phase change cold storage materials

[0034]

[0035]

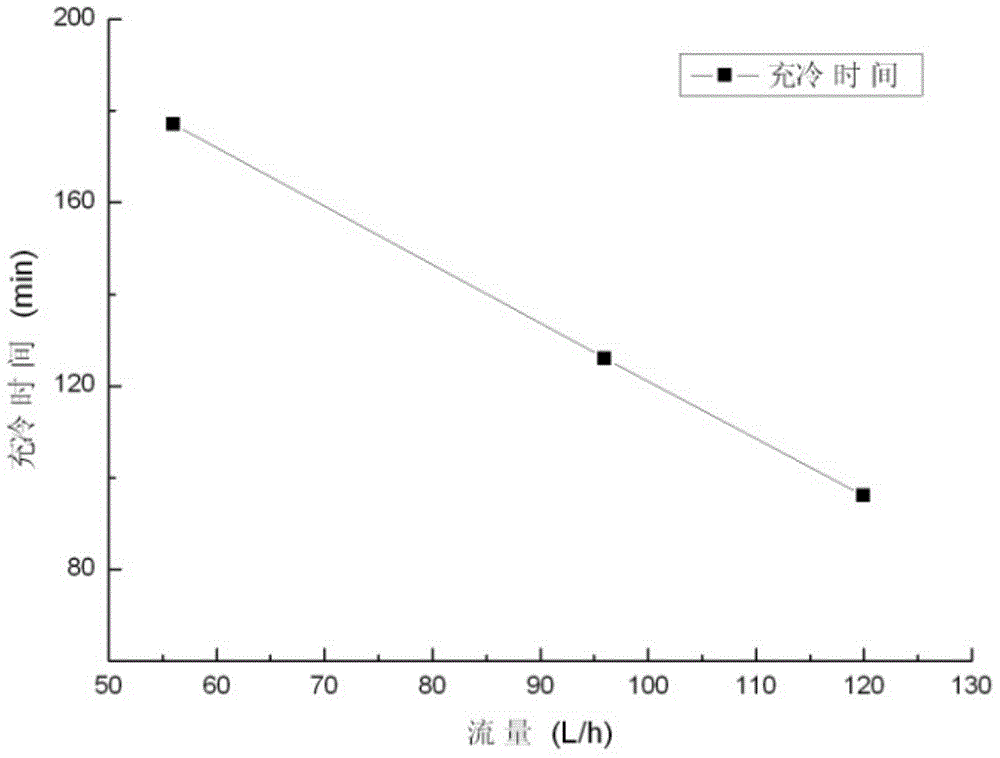

[0036] It can be seen from Table 3 that when the flow rate is 120L / h, compared with n-hexanol, the phase change charging and cooling time of expanded graphite + n-hexanol phase change material is shortened by 41%, which also shows that the phase change is greatly increased after adding expanded graphite. Thermal conductivity of cold storage materials. The cooling time and cooling flow rate of expanded graphite + n-hexanol phase change material show a lin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com