Bacillus amyloliquefaciens Y10 and application thereof

A technology of amylolytic spores and bacillus, applied in the direction of bacteria, water/sludge/sewage treatment, biochemical equipment and methods, etc., can solve problems such as no related reports, achieve broad social benefits, improve degradation efficiency, and be practical and economical Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

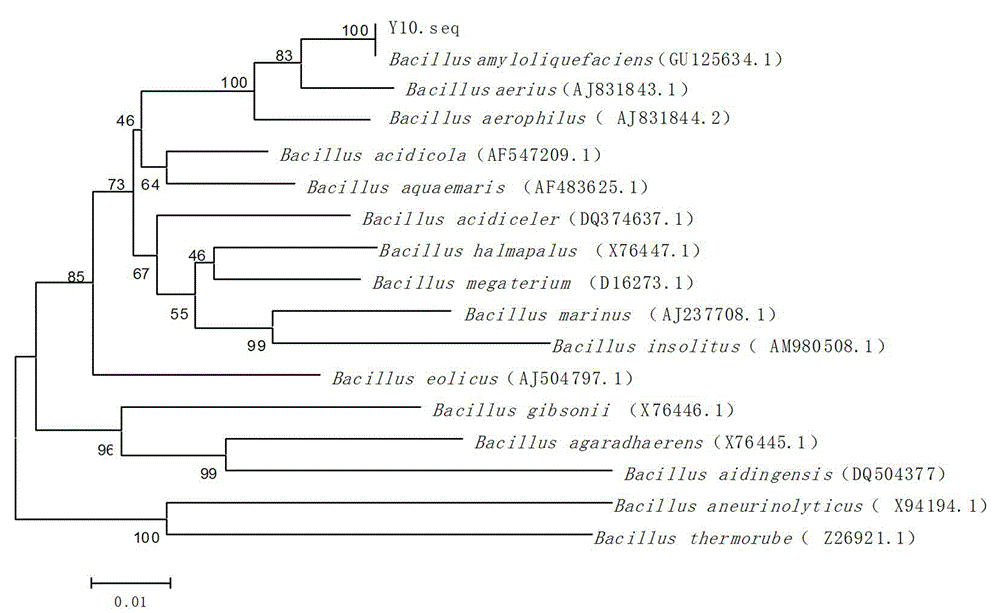

[0020] Example 1 Isolation and preservation of Bacillus amyloliquefaciens Y10

[0021] Bacillus amyloliquefaciens Y10 was isolated from the soil around the canteen of Hebei Academy of Sciences by gradient dilution method.

[0022] The specific method is: Weigh 10 g of soil from the place polluted by leftovers and leftovers around the cafeteria of the Hebei Academy of Sciences, add it to a triangular flask filled with 90 mL of sterile water and glass beads, shake it on a shaker for 30 min (150 r / min), serially diluted to make 10 -5 、10 -6 Dilute the suspension, draw 100 μL each, add it to the primary screening medium plate, spread it evenly with a coating bar, and repeat each treatment 3 times. The above-mentioned petri dishes were placed in a constant temperature incubator at 25 °C for 2-3 days. Select a single colony with a large transparent circle and grow quickly, transfer it to the slant of the LB test tube, and store it at 4 °C. The isolated strains were cultured in...

Embodiment 2

[0036] Example 2 Determination of Bacillus amyloliquefaciens Y10 enzyme activity

[0037] The isolated strains were placed in LB liquid medium and cultured in an incubator at 25 °C for 72 h. The fermentation broth was centrifuged at 4 °C and 8000 r / min for 10 min, and the supernatant was taken to determine amylase, protease and fat Enzyme activity.

[0038] The measurement methods are respectively used:

[0039] Determination method of amylase: national standard GB / T 24401-2009.

[0040]Definition of enzyme activity: 1 g of solid enzyme powder (or 1 mL of liquid enzyme), at 60 °C and pH 6.0, liquefies 1 g of soluble starch for 1 hour, which is 1 enzyme activity unit, expressed in u / g (u / mL) said.

[0041] Protease determination method: national standard GB / T 23527-2009 (Forint method).

[0042] Definition of enzyme activity: 1 g of solid enzyme powder (or 1 mL of liquid enzyme), under certain temperature and pH conditions (this patent uses 40°C, pH 7.0), hydrolyzes casein...

Embodiment 3-7

[0046] Example 3-7 Application of Bacillus amyloliquefaciens Y10 in anaerobic fermentation of kitchen waste

[0047] A 5 L fully mixed anaerobic fermentation device was used, with kitchen waste as raw material, the inoculum was from a normal fermentation biogas digester, the inoculum amount was 20-30% (volume ratio), and the final anaerobic fermentation liquid TS was 6-10% ( TS, also known as dry matter concentration, refers to placing a certain amount of fermentation feed liquid in an oven at 105 °C and drying it to a constant weight (the percentage of dry matter in the total weight), according to 5-20% of the total amount of anaerobic fermentation liquid Insert Bacillus amyloliquefaciens Y10 bacterial liquid, the total number of bacteria contained in the bacterial liquid is ≥10 9 individual / mL. Fermentation at room temperature (25±1 ℃) for 50 days increased biogas production by 20-38%. Fermentation at medium temperature (35±1 ℃) for 30 days increased biogas production by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com