Preparation method of a homogeneous bioceramic implant material containing gradient calcium and phosphorus

A bio-ceramic and implant technology, applied in electrolytic coatings, coatings, surface reaction electrolytic coatings, etc., can solve the problem of difficult calcium and phosphorus content and pore structure, oxidation voltage and frequency should not be too high, and lack of calcium and phosphorus in the ceramic layer. Content gradient and other problems, to achieve the effect of good biocompatibility, good osteoinductive and osseointegration performance, and uniform micropores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

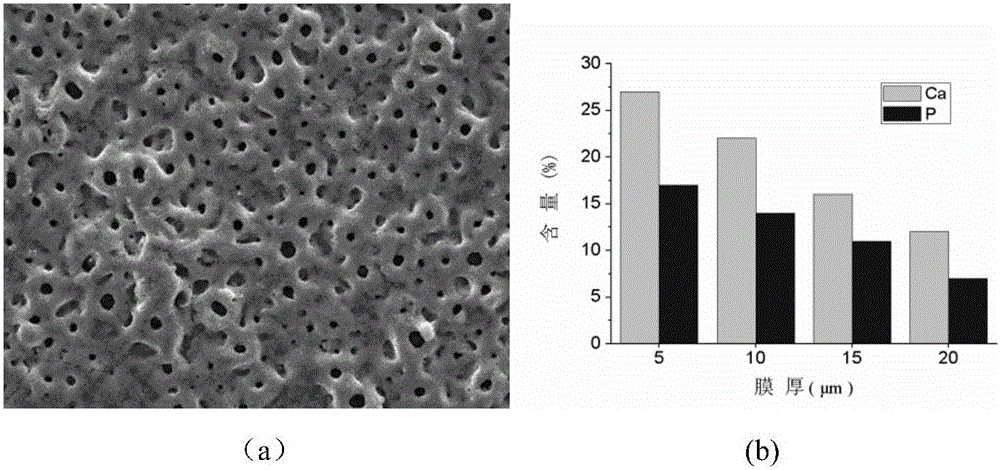

[0019] Perform micro-arc oxidation treatment on titanium or titanium alloy in 1L of ice-water mixed low-temperature electrolyte containing calcium and phosphorus, freeze deionized water (or distilled water) into 1L of ice and place it in the electrolyte. The process parameters are: constant voltage micro-arc oxidation process, electrode voltage U=650V, electrode frequency f=800Hz, duty cycle d=15%, micro-arc oxidation treatment time t=20min; electrolyte contains calcium ion concentration C( Ca)=15mmol / L, phosphorus ion concentration C(P)=3mmol / L. The surface micropores of the oxide film obtained by treating the titanium surface with this process are uniform and uniform, and the phase composition is anatase TiO 2 + rutile phase TiO 2 +CaTiO 3 + PO 4 3- group, the thickness of the oxide film is 22.8 μm, the Ca / P in the oxide film is 1.608, the critical load value is 29.7N, and the maturation period of the bone interface is shortened from 3 to 6 months for titanium implants t...

Embodiment 2

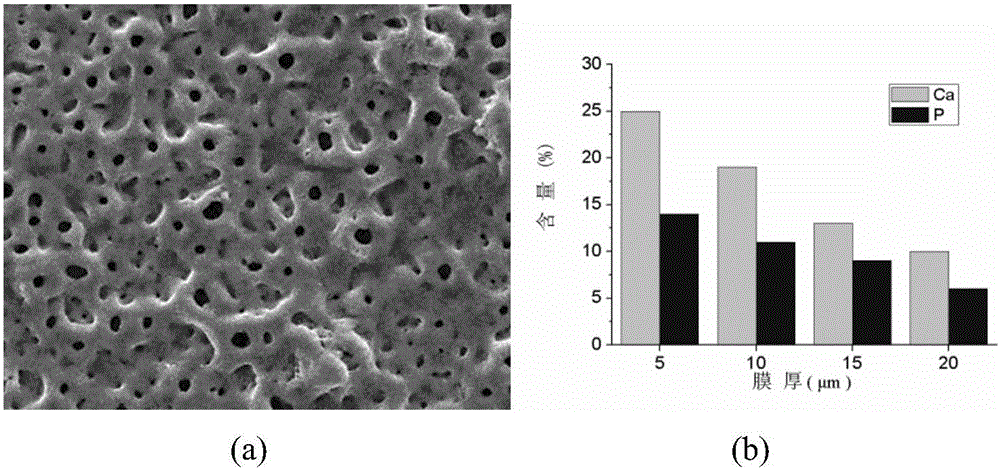

[0021] Perform micro-arc oxidation treatment on titanium or titanium alloy in 1L of ice-water mixed low-temperature electrolyte containing calcium and phosphorus, freeze deionized water (or distilled water) into 1L of ice and place it in the electrolyte. The process parameters are: constant voltage micro-arc oxidation process, electrode voltage U=600V, electrode frequency f=700Hz, duty cycle d=15%, micro-arc oxidation treatment time t=25min; electrolyte contains calcium ion concentration C( Ca)=20mmol / L, phosphorus ion concentration C(P)=4mmol / L. The micropores on the surface of the oxide film obtained by treating the titanium surface with this process are uniform and uniform.

Embodiment 3

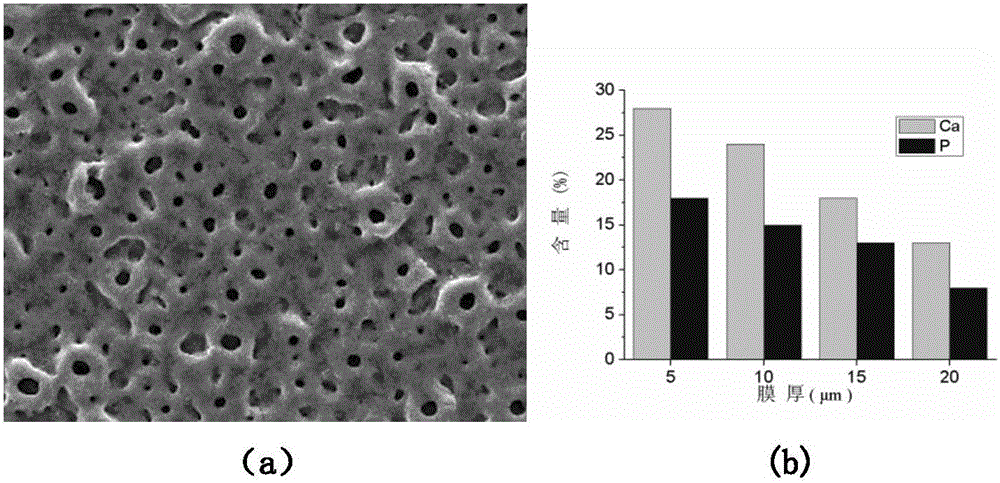

[0023] Perform micro-arc oxidation treatment on titanium or titanium alloy in 1L of ice-water mixed low-temperature electrolyte containing calcium and phosphorus, freeze deionized water (or distilled water) into 1L of ice and place it in the electrolyte. The process parameters are: constant voltage micro-arc oxidation process, electrode voltage U=700V, electrode frequency f=900Hz, duty cycle d=20%, micro-arc oxidation treatment time t=15min; electrolyte contains calcium ion concentration C( Ca)=10mmol / L, phosphorus ion concentration C(P)=2mmol / L. The micropores on the surface of the oxide film obtained by treating the titanium surface with this process are uniform and uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com