Method for Controlling Crystallization Speed in Silicon Ingot Casting

A technology of silicon ingot casting and crystallization speed, applied in chemical instruments and methods, crystal growth, single crystal growth and other directions, can solve the problems of inability to accurately control the crystallization of silicon liquid, and achieve the effect of stabilizing the crystallization quality of liquid silicon and avoiding hysteresis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

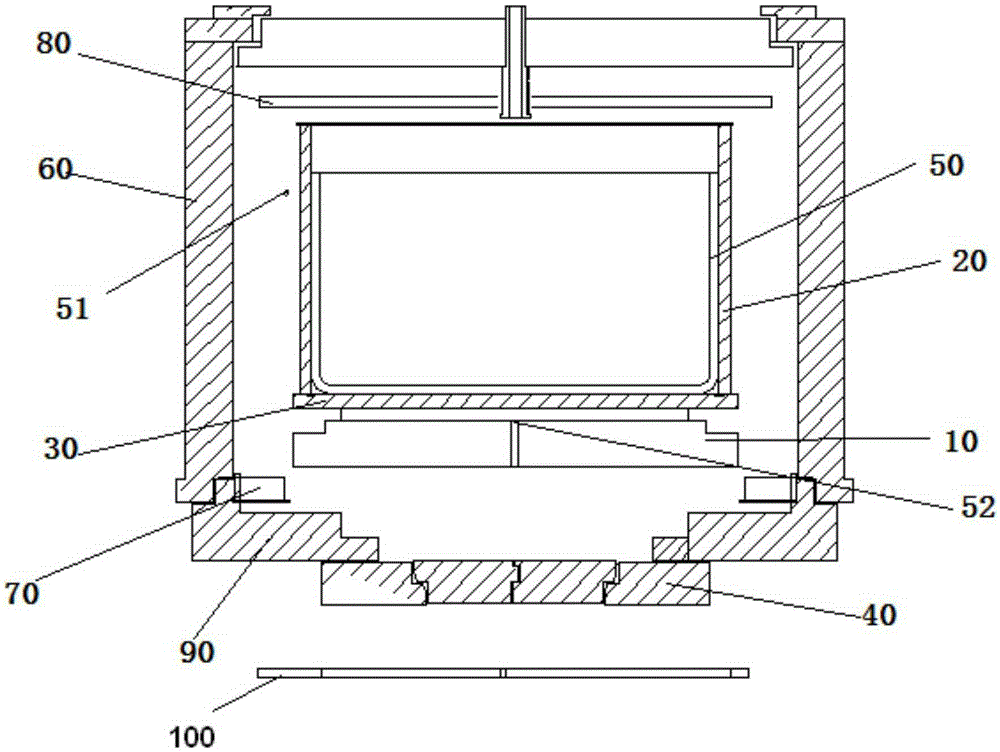

[0047] The first step: the opening of the shutter is 28 degrees, the bottom of the silicon liquid begins to dissipate heat, and the temperature at the top temperature measurement point 51 is maintained above the melting point of the silicon liquid, and the top of the silicon liquid is kept from crystallizing for 60 minutes;

[0048] The second step: on the basis of the first step, continue to open the louvers at a constant speed to an angle of 38 degrees, and the temperature setting of the top temperature measuring point 51 is slightly lowered by 3°C, and the time is 60 minutes;

[0049] The third step is to control the output power of the ingot furnace to 59kw, the louver opening angle is 48 degrees, and the time is 300 minutes;

[0050] The fourth step is to control the output power of the ingot furnace to 64kw, the louver opening angle is 63 degrees, and the time is 240 minutes;

[0051] The fifth step is to control the output power of the ingot furnace to 69kw, the louver opening a...

Embodiment 2

[0056] The first step: the opening of the shutter is 22 degrees, the bottom of the silicon liquid begins to dissipate heat, and the temperature at the top temperature measurement point 51 is maintained above the melting point of the silicon liquid, and the top of the silicon liquid is kept from crystallizing for 30 minutes;

[0057] The second step: on the basis of the first step, continue to open the louvers at a constant speed to an angle of 32 degrees, and the temperature setting of the top temperature measurement point 51 is slightly lowered by 3°C, and the time is 30 minutes;

[0058] The third step is to control the output power of the ingot furnace to 51kw, the louver opening angle is 42 degrees, and the time is 240 minutes;

[0059] The fourth step is to control the output power of the ingot furnace to 56kw, the louver opening angle is 57 degrees, and the time is 240 minutes;

[0060] The fifth step is to control the output power of the ingot furnace to 61kw, the louver opening...

Embodiment 3

[0065] The first step: the opening of the shutter is 27 degrees, the bottom of the silicon liquid begins to dissipate heat, and the temperature at the top temperature measurement point 51 is maintained above the melting point of the silicon liquid, and the top of the silicon liquid is kept from crystallizing for 40 minutes;

[0066] The second step: on the basis of the first step, continue to open the louvers at a constant speed to an angle of 37 degrees, and the temperature setting of the top temperature measurement point 51 is reduced by 2° C., and the time is 40 minutes;

[0067] The third step is to control the output power of the ingot furnace to 57kw, the louver opening angle is 47 degrees, and the time is 270 minutes;

[0068] The fourth step is to control the output power of the ingot furnace to 62kw, the louver opening angle is 62 degrees, and the time is 270 minutes;

[0069] The fifth step is to control the output power of the ingot furnace to 67kw, the louver opening angle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com