Preparation method for fermented milk

A technology of fermented milk and curd milk, applied in dairy products, milk preparations, applications, etc., to achieve the effects of reducing energy consumption, not easy to spoil, and prolonging the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

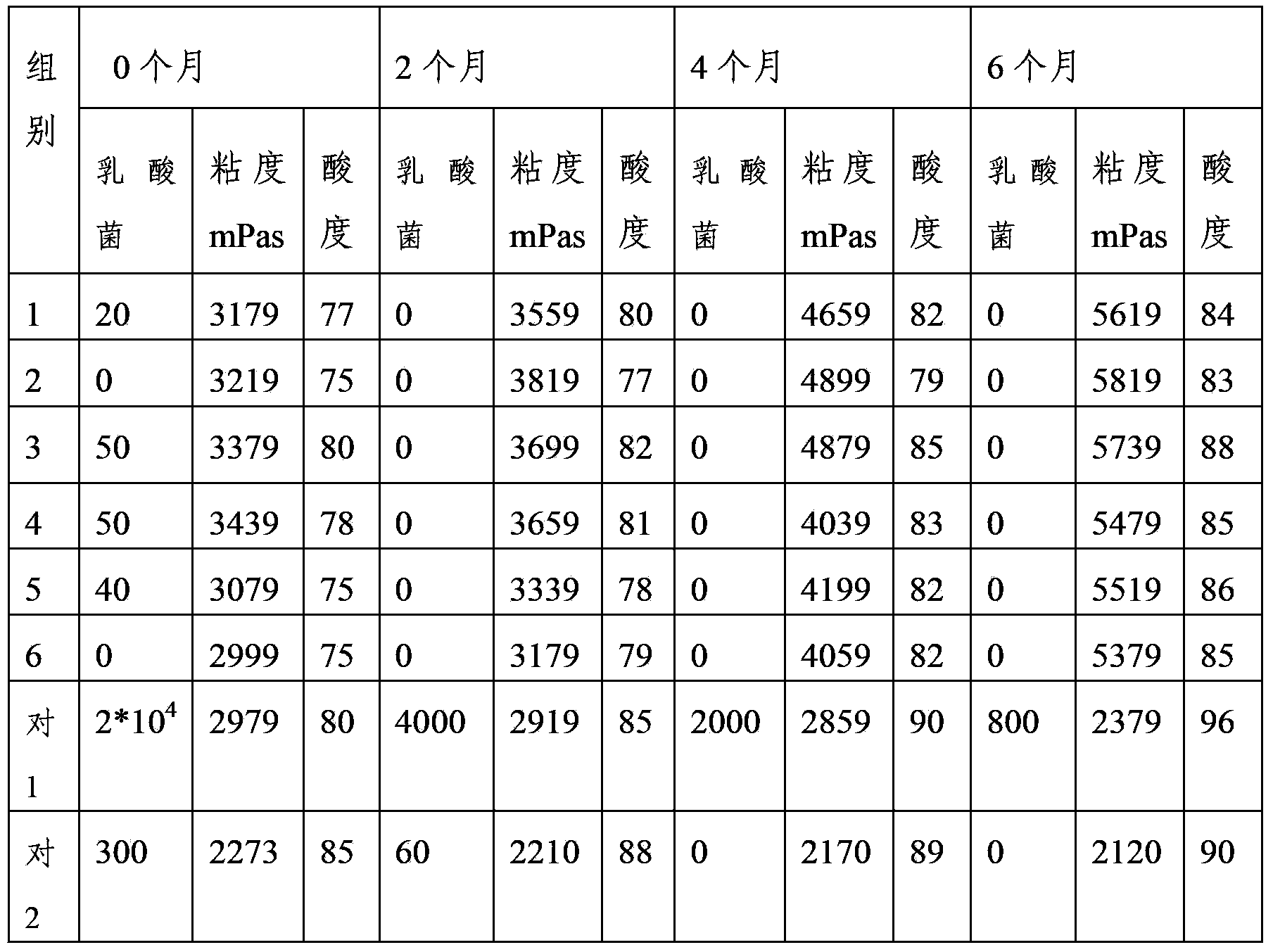

Examples

Embodiment 1

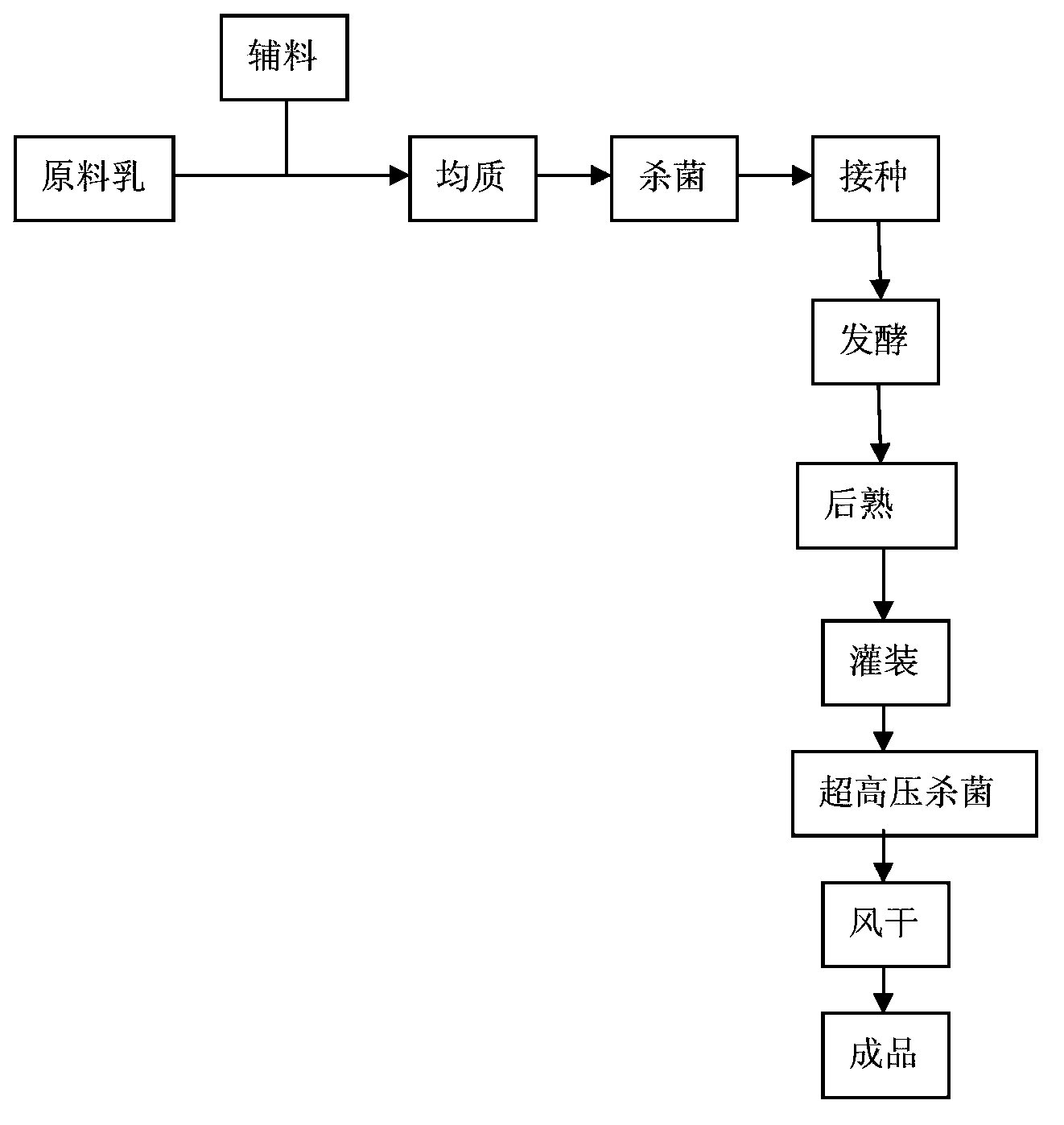

[0030] see figure 1 . Mix 100 parts of qualified raw milk (parts by mass, the same below), 0.1 part of modified starch (modified corn starch, Tianjin Dingfeng Starch Co., Ltd.), 0.1 part of pectin and 2 parts of white granulated sugar. Homogenize at 20MPa, sterilize at 95°C for 5min, add 2 parts of fermented bacteria (1:1 Lactobacillus bulgaricus and Streptococcus thermophilus) after cooling; ferment at 43°C, when the titrated acidity is 85°C, it becomes coagulant Milk, stop fermentation and refrigerate at 5°C for 10 hours before ripening. Then directly fill the fermented milk into composite plastic bags (PET-aluminum foil-PE composite plastic bags), raise the temperature to 30°C, and sterilize the bagged fermented milk with vertical high static pressure sterilization equipment.

[0031] Vertical high static pressure sterilization equipment, pressurized by pure water, also has a heating and heat preservation system to achieve temperature control.

[0032] The working proces...

Embodiment 2

[0034] Use the same method as in Example 1 to mix the qualified raw milk, modified starch, pectin, white sugar and other auxiliary materials evenly, then homogenize at 60°C and 20MPa, and sterilize at 95°C for 5min, add after cooling Two parts of fermented strains (1:1 Lactobacillus bulgaricus and Streptococcus thermophilus) were fermented at 43°C, when the titrated acidity was 85°C, the fermentation was stopped and refrigerated at 6°C for 10 hours to post-ripen. Then the fermented milk is directly filled into a composite plastic bag (PET-aluminum foil-PE composite plastic bag), the bagged fermented milk is heated to 30°C, and sterilized with a vertical high static pressure sterilization equipment.

[0035] Sterilize at 30°C and 500MPa for 10 minutes, then increase the pressure to 600MPa, sterilize for 5 minutes, remove from the working chamber, and air-dry the moisture outside the package.

Embodiment 3

[0037]According to the method of Example 1, after mixing the qualified raw material milk, modified starch, pectin and white sugar and other auxiliary materials evenly, homogenize at 60°C and 20MPa, and sterilize at 95°C for 5min, add fermentation bacteria after cooling bulgaricus and 2 parts of Streptococcus thermophilus, and 0.2 parts of Bifidobacterium) were fermented at 43°C, and the fermentation was terminated when the titrated acidity was 85°C and refrigerated at 4°C for 12 hours before ripening.

[0038] Then directly fill the fermented milk into a composite plastic bag (PET-aluminum foil-PE composite plastic bag), raise the temperature to 30°C, put the bagged fermented milk into a vertical high-pressure chamber, and sterilize at 30°C and 550MPa for 15 minutes Finally, air-dry the outer moisture of the package to obtain the product of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com