Whole grain protein beverage and preparation method thereof

A protein drink and whole grain technology, which is applied in the field of whole grain protein drink and its preparation, achieves the effects of thin, fresh and delicate taste, regulation of blood lipids and easy operation

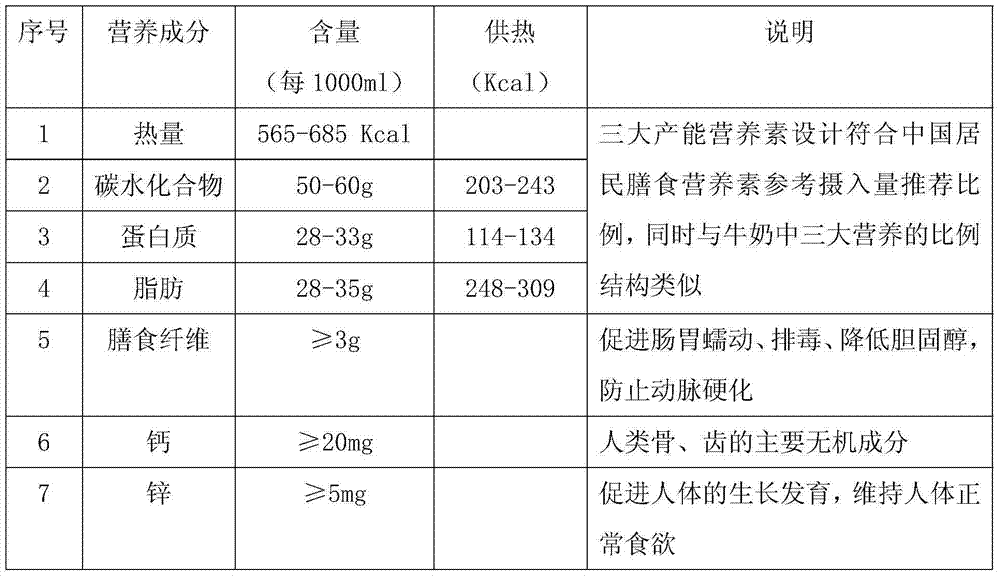

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The required raw material formula is: oat 6%. 4% soybeans, 1% naked barley, 1% walnuts, 0.5% hazelnuts, 0.5% peas, 0.5% pine nuts, 0.5% red kidney beans, 2% white sesame, 1% corn, 0.5% rice, 0.5% millet, wheat 1%, white granulated sugar 2%, stabilizer 3%, enzyme preparation (0.2% by grain mass), and the balance is water.

[0055] The stabilizer composition and its mass ratio content are: 100 monoglycerides, 35 carrageenans, 5 xanthan gums, 10 locust bean gums, 35 sucrose esters, and 15 sodium tripolyphosphate. The raw material specification is best to choose sucrose ester with HLB value of 11, and sodium tripolyphosphate as food grade.

[0056] The composition of the enzyme preparation and its mass ratio content are: 25% amylase and 50% glucoamylase.

[0057] The preparation method of the whole grain protein beverage of the present invention comprises the following steps:

[0058] 1) Soak various grains in room temperature water for 3 hours.

[0059] 2) Boil the soa...

Embodiment 2

[0074] The required raw material formula is: oat 4%. 5% soybeans, 0.5% naked barley, 0.5% walnuts, 1% hazelnuts, 0.8% peas, 2% pine nuts, 0.2% red kidney beans, 0.5% white sesame, 0.7% corn, 0.7% rice, 0.7% millet, wheat 1.5%, white sugar 4%, stabilizer 4%, enzyme preparation (0.3% by grain mass), and the balance is water.

[0075] The stabilizer composition and its mass ratio content are: 100 monoglyceride, 30 carrageenan, 10 xanthan gum, 15 locust bean gum, 40 sucrose ester, and 15 sodium tripolyphosphate. The raw material specification is best to choose sucrose ester with HLB value of 11, and sodium tripolyphosphate as food grade.

[0076] The composition of the enzyme preparation and its content by mass ratio are: 30% amylase and 60% glucoamylase.

[0077] The preparation method of the whole grain protein beverage of the present invention comprises the following steps:

[0078] 1) Soak various grains in room temperature water for 4 hours.

[0079] 2) Boil the soaked gr...

Embodiment 3

[0094] The required raw material formula is: oat 5%. Soybean 4.5%, naked barley 0.75%, walnut 0.75%, hazelnut 0.75%, pea 0.7%, pine nut kernel 1.25%, red kidney bean 0.3%, white sesame 1.25%, corn 0.8%, rice 0.6%, millet 0.6%, wheat 1.25%, white granulated sugar 6%, stabilizer 5%, enzyme preparation (0.4% by grain mass), and the balance is water.

[0095] The stabilizer composition and its mass ratio content are: 100 monoglycerides, 40 carrageenans, 15 xanthan gums, 5 locust bean gums, 50 sucrose esters, and 20 sodium tripolyphosphate. The raw material specification is best to choose sucrose ester with HLB value of 11, and sodium tripolyphosphate as food grade.

[0096] The composition of the enzyme preparation and its content by mass ratio are: 35% amylase and 70% glucoamylase.

[0097] The preparation method of the whole grain protein beverage of the present invention comprises the following steps:

[0098] 1) Soak various grains in room temperature water for 5 hours.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com