Preparation method of sequential black mesoporous titanium dioxide visible light catalyst film

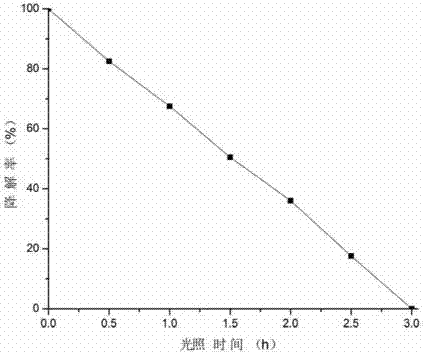

A mesoporous titanium dioxide, titanium dioxide technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficult catalyst recovery, ineffective absorption of titanium dioxide, etc., and achieve low cost and photocatalytic efficiency. The effect of improving and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific Embodiment 1: In this embodiment, a method for preparing an ordered black mesoporous titanium dioxide visible light catalyst film is realized according to the following steps:

[0021] 1. Impregnation: immerse 10g-25g of porous ceramic membrane in 100mL ordered mesoporous titania sol for 4h-12h to obtain a porous ceramic membrane impregnated with titania sol;

[0022] 2. Drying: drying the porous ceramic membrane impregnated with titanium dioxide sol obtained in step 1 at a temperature of 60°C to 90°C for 12h to 24h to obtain a porous ceramic membrane of titanium dioxide sol;

[0023] 3. Heat treatment: Put the porous ceramic membrane of titanium dioxide sol obtained in step 2 into a roasting furnace, raise the temperature to 400°C-800°C at a heating rate of 1°C / min-20°C / min and keep it for 2h-8h, then take it out and cool To room temperature, obtain the porous ceramic film of the titanium dioxide sol after heat treatment;

[0024] 4. Hydrogenation: put the po...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that the porous ceramic membrane described in step 1 is a porous aluminosilicate membrane or a porous silicon dioxide membrane. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the preparation method of the ordered mesoporous titania sol described in step one, is to realize according to the following steps:

[0029] Add 4 mL of concentrated hydrochloric acid dropwise to 5 mL of isopropyl titanate and stir for 2 hours to obtain solution A; dissolve 1.5 g of triblock polymer P123 in 20 mL of absolute ethanol and stir for 1 hour to obtain solution B , Add solution B into solution A, stir for 4 hours, and age for 10 hours to obtain a transparent sol, which is an ordered mesoporous titania sol. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com