Water soluble polyvinyl alcohol micropore membrane and production method thereof

A polyvinyl alcohol, microporous film technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve problems such as insufficient air permeability, gram weight, etc., to avoid infection risks and reduce operating costs. , the effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] With following proportioning, polyvinyl alcohol aqueous solution is prepared in polyvinyl alcohol dissolution reactor 1:

[0065] Polyvinyl alcohol 1799 resin 100

[0066] Lauryl alcohol polyoxyethylene ether 6.25

[0067] water 1150

[0068] The above mixed solution was heated to 85-95°C while stirring, and after stirring for 2 hours, the polyvinyl alcohol resin was completely dissolved. The solution is stored in the temporary storage tank 2, filtered through the primary filter 5, cooled by the heat exchanger 6 to maintain a constant temperature, vacuum degassed in the defoaming kettle 7, and then enters the heat preservation tank 8 for storage. The polyvinyl alcohol aqueous solution stored in the thermal insulation storage tank 8 enters the coating machine 12a after the high-pressure metering pump 9 and the static mixer 10 and the final filter 11, and is evenly coated on the PET film base material 13 to form a wet Film, coat weight 250 gsm.

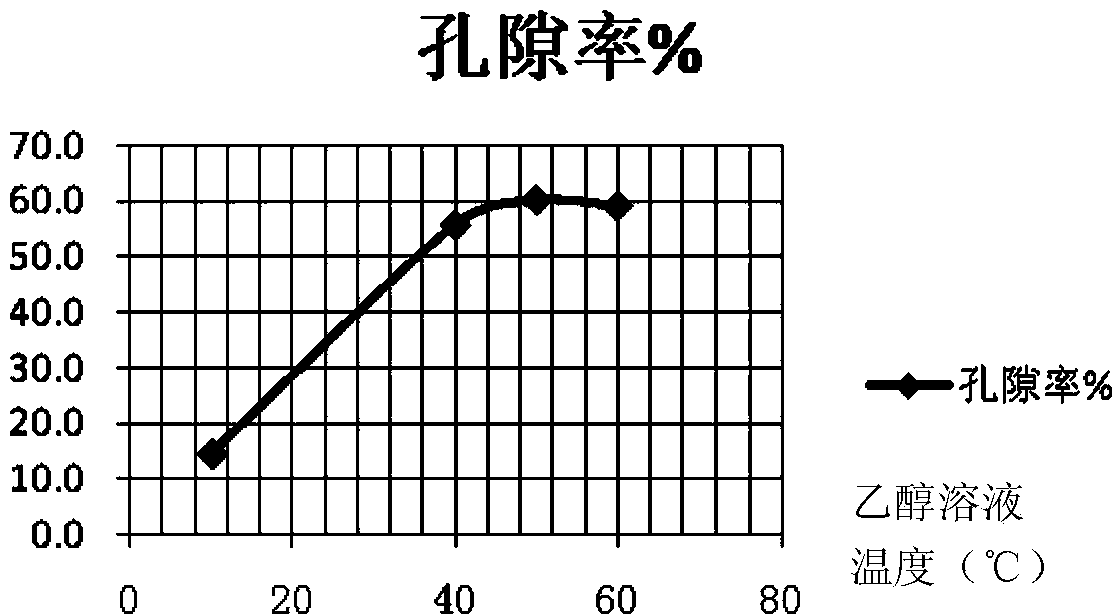

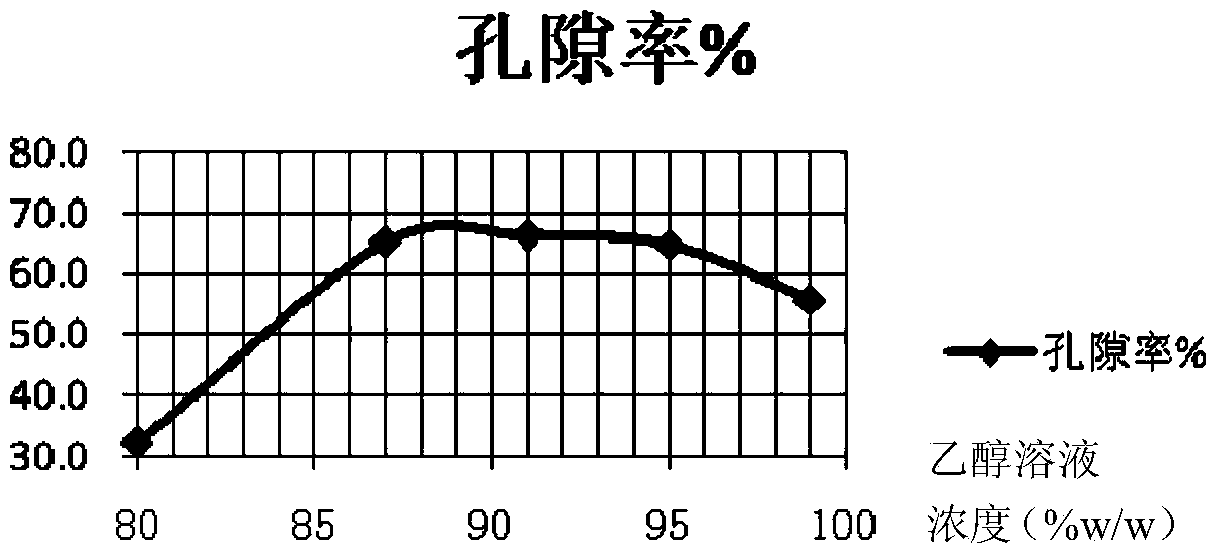

[0069] After the wet ...

Embodiment 2

[0077] Prepare the mixture in the following proportions:

[0078] Lauric acid 10

[0079] Lauryl alcohol polyoxyethylene ether 18.5

[0080] water 1116

[0081] After the above mixed solution is heated to 85-95°C while stirring in the polyvinyl alcohol dissolution reactor 1, a light blue translucent emulsion is formed. After adding 100 parts of 1799 polyvinyl alcohol resin, continue to insulate and stir for 2 hours to completely dissolve the polyvinyl alcohol resin. The dissolved polyvinyl alcohol aqueous solution is cooled to about 40° C. through the condenser 6, sent to the primary filter 5 for filtration with the pump 4, and stored in the temporary storage tank 2 for use. Use the pump 4 to send the polyvinyl alcohol aqueous solution from the temporary storage tank 2 to the vacuum defoaming kettle 7 for vacuum degassing, and put it in the heat preservation storage tank 8 to keep it at a constant temperature for 30 minutes, then through the high pressure metering pump 9, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com