Method for treating waste mobile phone circuit board and recovering precious metals

A precious metal and circuit board technology, applied in the field of mobile phone circuit board processing, can solve the problems of high processing cost, environmental pollution, waste of valuable resources, etc., achieve good processing effect, high added value, and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

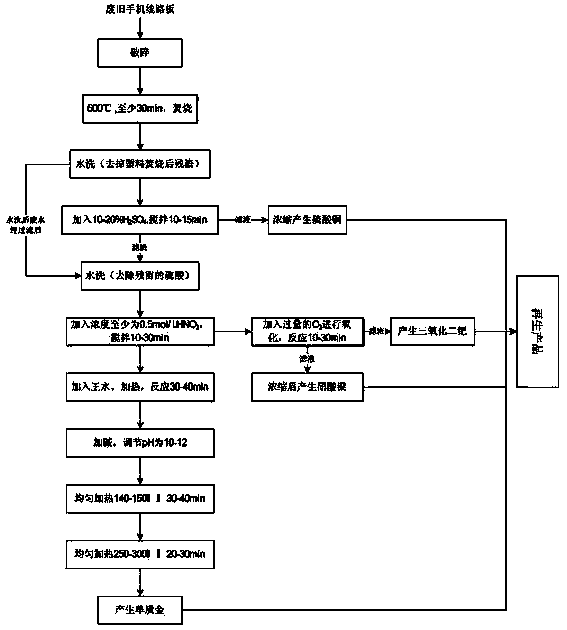

Image

Examples

Embodiment 1

[0033] A method for processing waste mobile phone circuit boards and recycling precious metals, the method is:

[0034] (1) After crushing 1kg of waste mobile phone circuit boards, incinerate at 600°C for 30 minutes, and collect the residue after incineration;

[0035] (2) Wash the residue after incineration with water, wash off the light substances (plastics, etc.) in the residue after incineration, and collect the residue after washing;

[0036] (3) Soak the washed residue in an excess of 20% H 2 SO 4 solution, after stirring for 12min, filter, and the filtrate is concentrated to produce CuSO 4 products, collected separately;

[0037] (4) Wash the filtered residue with water to remove residual H 2 SO 4 ;

[0038] (5) Soak the residue after washing in step (4) in 0.5mol / L HNO 3 Solution, after stirring for 30min, filter, collect filtrate and filter residue respectively;

[0039] (6) Continuously feed O into the filtrate collected in step (5) 3 Carry out the oxidation...

Embodiment 2

[0045] A method for processing waste mobile phone circuit boards and recycling precious metals, the method is:

[0046] (1) After crushing 1kg of waste mobile phone circuit boards, incinerate at 600°C for 30 minutes, and collect the residue after incineration;

[0047] (2) Wash the residue after incineration with water, wash off the light substances (plastics, etc.) in the residue after incineration, and collect the residue after washing;

[0048] (3) Soak the washed residue in an excess of 10% H 2 SO 4 solution, after stirring for 10min, filter, and the filtrate is concentrated to produce CuSO4 products, collected separately;

[0049] (4) Wash the filtered residue with water to remove residual H 2 SO 4 ;

[0050] (5) Soak the residue after washing in step (4) in 0.5mol / L HNO 3 Solution, after stirring for 30min, filter, collect filtrate and filter residue respectively;

[0051] (6) Continuously feed O into the filtrate collected in step (5) 3 Carry out the oxidation r...

Embodiment 3

[0057] A method for processing waste mobile phone circuit boards and recycling precious metals, the method is:

[0058] (1) After crushing 1kg of waste mobile phone circuit boards, incinerate at 600°C for 30 minutes, and collect the residue after incineration;

[0059] (2) Wash the residue after incineration with water, wash off the light substances (plastics, etc.) in the residue after incineration, and collect the residue after washing;

[0060] (3) Soak the washed residue in an excess of 20% H 2 SO 4 solution, after stirring for 10min, filter, and the filtrate is concentrated to produce CuSO 4 products, collected separately;

[0061] (4) Wash the filtered residue with water to remove residual H 2 SO 4 ;

[0062] (5) Soak the residue after washing in step (4) in 0.5mol / L HNO 3 Solution, after stirring for 30min, filter, collect filtrate and filter residue respectively;

[0063] (6) Continuously feed O into the filtrate collected in step (5) 3 Carry out the oxidation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com