A method for rapid evaluation of the adsorption effect of porous filter additives

An additive and porosity technology, which is applied in the field of rapid evaluation of the adsorption effect of porous filter additives, can solve the problems of high cost, large waste, and inconsistent filter addition methods (evenly distributed in acetate fibers, etc., to save steps and costs, Easy operation and high test sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

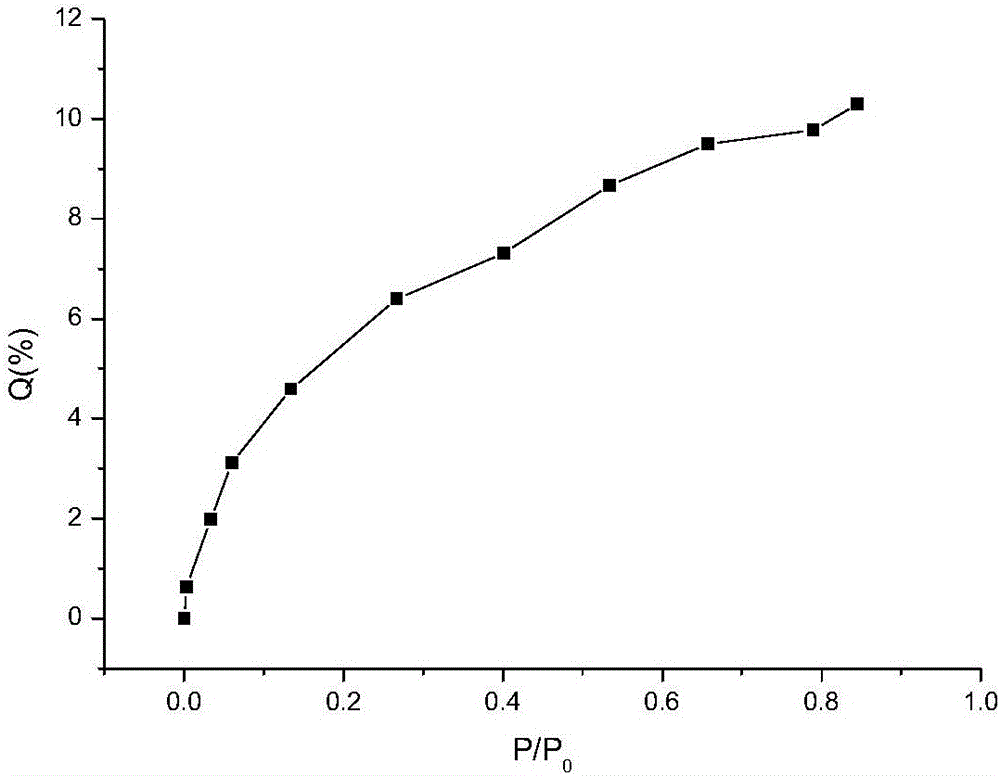

[0027] The toxic substance is n-butyraldehyde, and the porous filter additives to be evaluated are powder additive 1 (molecular sieve), additive 2 (molecular sieve), and additive 3 (micro-medium composite porous material).

[0028] (1) Preliminary degassing of additives: Weigh 150-200mg of the above three additives respectively, and use a specific surface area meter to degas overnight at 180°C to initially remove impurity gases in the filter additives.

[0029] (2) Pipette 5-15ml of n-butyraldehyde liquid into the vaporization storage tank, weigh 50-100mg of the filter additive after preliminary degassing treatment, and put it into the quartz hanging basket of the intelligent gravimetric absorption instrument.

[0030] (3) Secondary degassing: Heat the sample to 180°C through an external heating device, keep it warm for 4 hours, and use a vacuum pump to further deeply remove the residual impurity gas in the additive.

[0031] (4) Adsorption: According to the saturated vapor pr...

Embodiment 2

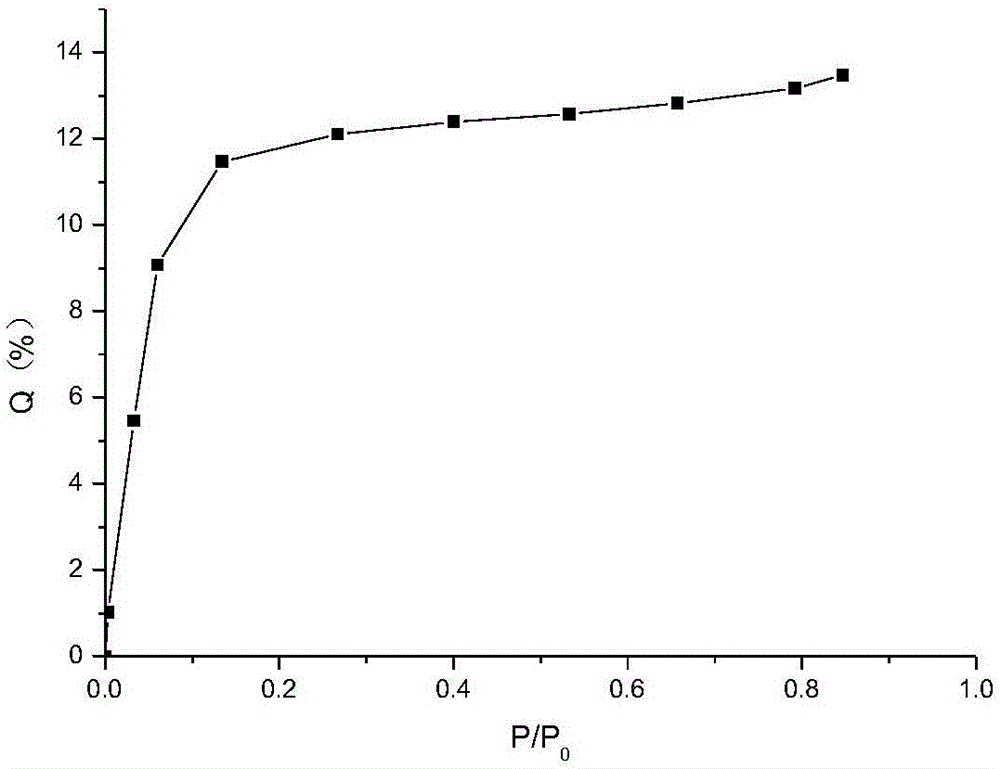

[0042] The toxic substance is selected as benzene, and the filter additives to be evaluated are powder additive 4 (molecular sieve) and additive 5 (micro-mesoporous material) on the adsorption effect of benzene series.

[0043] (1) Preliminary degassing of additives: Weigh 150-200mg of the above two additives respectively, and use a specific surface area meter to degas overnight at 180°C to initially remove impurity gases in the filter additives.

[0044] (2 Pipette 5-15ml of benzene liquid into the vaporization storage tank, weigh 50-100mg of the filter additive after preliminary degassing treatment, and put it into the quartz hanging basket of the intelligent gravimetric absorption instrument.

[0045] (3) Secondary degassing: Heat the sample to 180°C through an external heating device, keep it warm for 4 hours, and use a vacuum pump to further deeply remove the residual impurity gas in the additive.

[0046] (4) Adsorption: According to the saturated vapor pressure of the s...

Embodiment 3

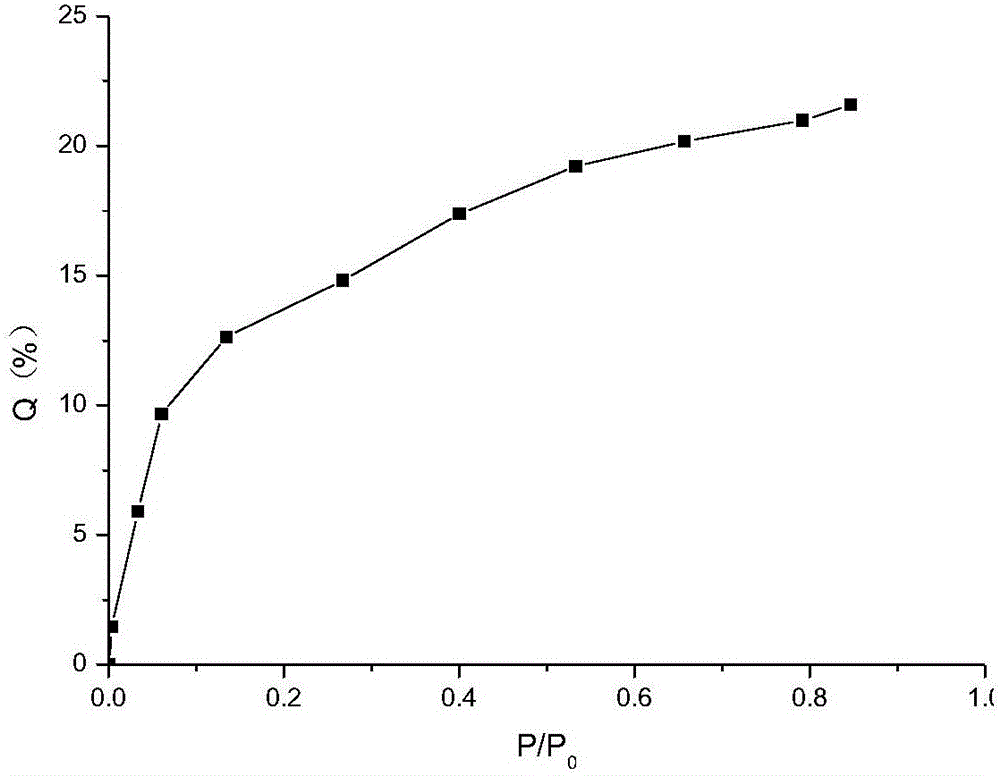

[0056] The toxic substance is selected as CO, and the filter additives to be evaluated are powdered additive 6 (molecular sieve) and additive 7 (micro-mesoporous material) for CO adsorption.

[0057] (1) Preliminary degassing of additives: Weigh 150-200mg of the above two additives respectively, and use a specific surface area meter to degas overnight at 180°C to initially remove impurity gases in the filter additives.

[0058] (2) Connect the CO gas bottle to the intelligent adsorption instrument, weigh 50-100 mg of the filter tip additive after preliminary degassing treatment, and put it into the quartz hanging basket of the intelligent gravimetric absorption instrument.

[0059] (3) Secondary degassing: Heat the sample to 180°C through an external heating device, keep it warm for 4 hours, and use a vacuum pump to further deeply remove the residual impurity gas in the additive.

[0060] (4) Adsorption: According to the saturated vapor pressure of the selected gas, set 27 test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com