Nano barium sulfate and preparation method thereof

A technology of nano barium sulfate and ammonium sulfate, applied in nanotechnology, nanotechnology, calcium/strontium/barium sulfate and other directions, can solve the problems such as the width of nano barium sulfate, the inability of nano barium sulfate to meet the requirements in the field of battery separators, and the like. The effect of mild process conditions and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

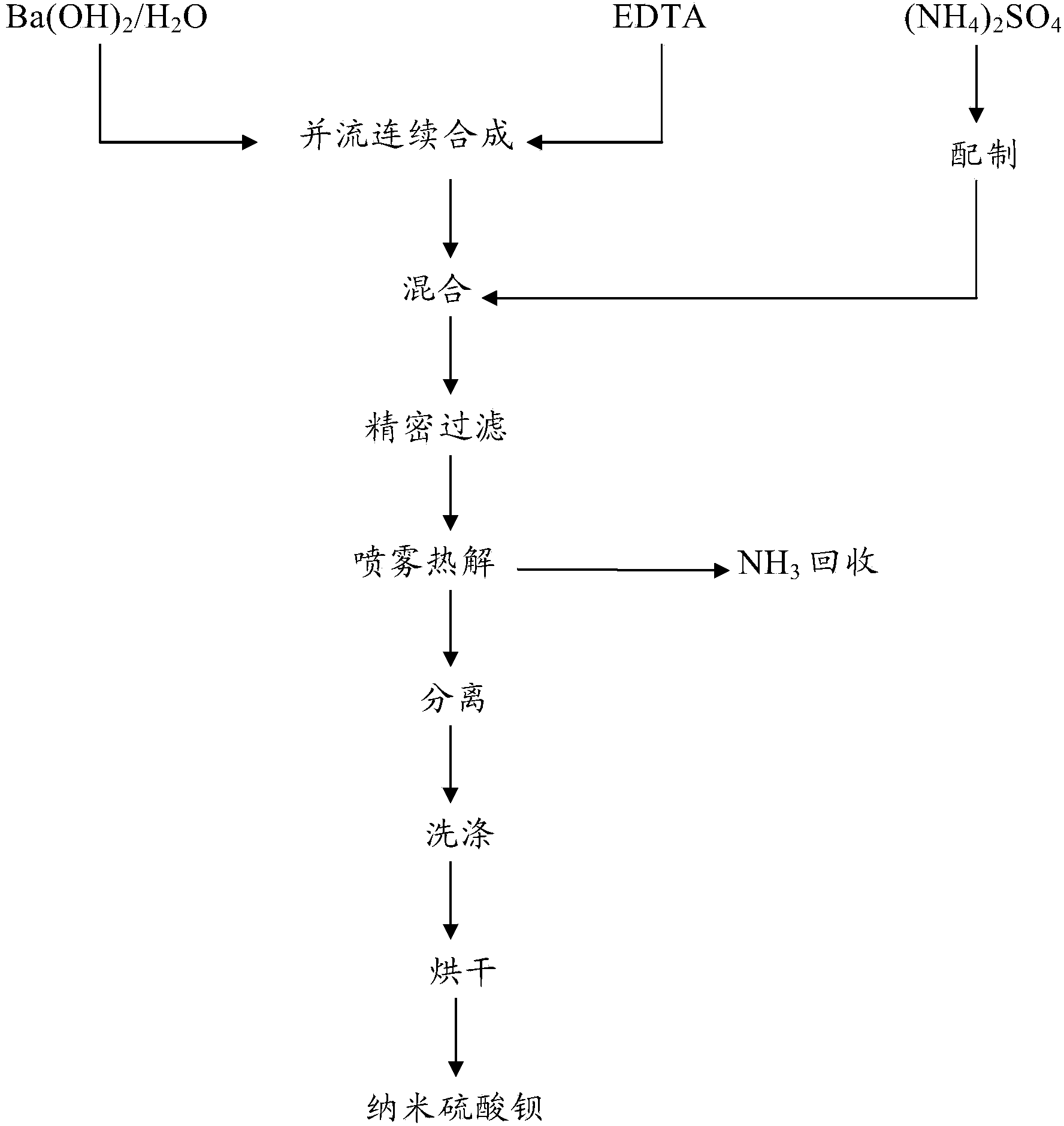

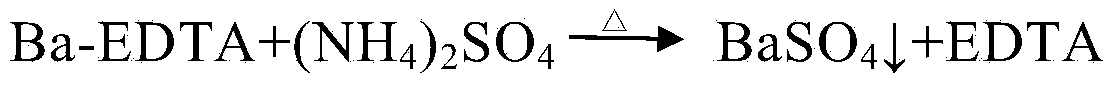

[0032] The preparation method of nanometer barium sulfate of the present invention comprises following steps:

[0033] (1) Raw material treatment process: Ba(OH) 2 ·8H 2 O is purified to obtain Ba(OH) with a calcium content of less than 200ppm 2 ·8H 2 O is crystallized, ammonium sulfate is purified to obtain ammonium sulfate with a calcium content of less than 200ppm; in a specific embodiment, Ba(OH) is obtained in operation (1) 2 ·8H 2 The calcium content in O is less than 50ppm; The calcium content in obtaining ammonium sulfate is preferably less than 50ppm; In a specific embodiment, the purified Ba(OH) described in operation (1) 2 ·8H 2 The method of O includes: preparing barium hydroxide concentration as Ba 2+ 0.5-2.5mol / L solution, the preferred concentration is 1.5-2.5mol / L, heated until completely dissolved, heat-preserved and filtered to obtain the filtrate, the filtrate is cooled to crystallize, the obtained crystal is subjected to solid-liquid separation, and t...

Embodiment 1

[0070] Combine below figure 1 Shown in the process flow diagram, the present invention prepares the process of nanometer barium sulfate.

[0071] (1) Raw material processing process

[0072] Determination of commercially available 1000kg industrial grade Ba(OH) 2 ·8H 2 Calcium content in O raw material is 473.2ppm, stand-by. Determination of commercially available 1000kg industrial grade (NH 4 ) 2 SO 4 The content of calcium in the medium is 525.6ppm.

[0073] (2) Preparation process of Ba-EDTA

[0074] The Ba(OH) obtained in step (1) 2·8H 2 O crystals are placed in a stirring heating pot and prepared to a concentration of 30 kg / m 3 barium hydroxide solution, add EDTA to make the concentration of EDTA in the solution after adding be 40 kg / m 3 , heat the mixed solution to 83°C, maintain the temperature for 35 minutes under stirring, then pass through cooling water to cool below 30°C, filter it precisely and accurately measure [Ba 2+ ] Concentration is 0.0477mol / L. ...

Embodiment 2

[0081] Combine below figure 1 Shown in the process flow diagram, the present invention prepares the process of nanometer barium sulfate.

[0082] (1) Raw material processing process

[0083] Will commercially buy 1000kg of industrial grade Ba(OH) 2 ·8H 2 The O raw material is prepared into a solution with a concentration of 2.5 mol / L, heated to 90°C under stirring, completely dissolved, heat-preserved and filtered, and the filter residue is discarded, the filtrate is cooled to 30°C for crystallization, separated by filtration, and the mother liquor is used to dissolve the barium hydroxide raw material. The crystal is used to prepare Ba-EDTA solution, and the calcium content in the crystal is determined to be 200ppm.

[0084] Will commercially buy 1000kg industrial grade (NH 4 ) 2 SO 4 Make a solution of 0.8mol / L, add ammonium carbonate under stirring to make the concentration of ammonium carbonate in the solution 2.4mol / L, stir at room temperature for 25 minutes, separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com