Advanced treatment method of integrated catalytic ozonation-biological aerated filter water

A technology of ozone catalytic oxidation and biological aerated filter, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. It can solve the problems that the stability of treatment effect needs to be further improved, and achieve protection Effects of biomass and biological activity, accelerated decomposition, and improved ozone use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

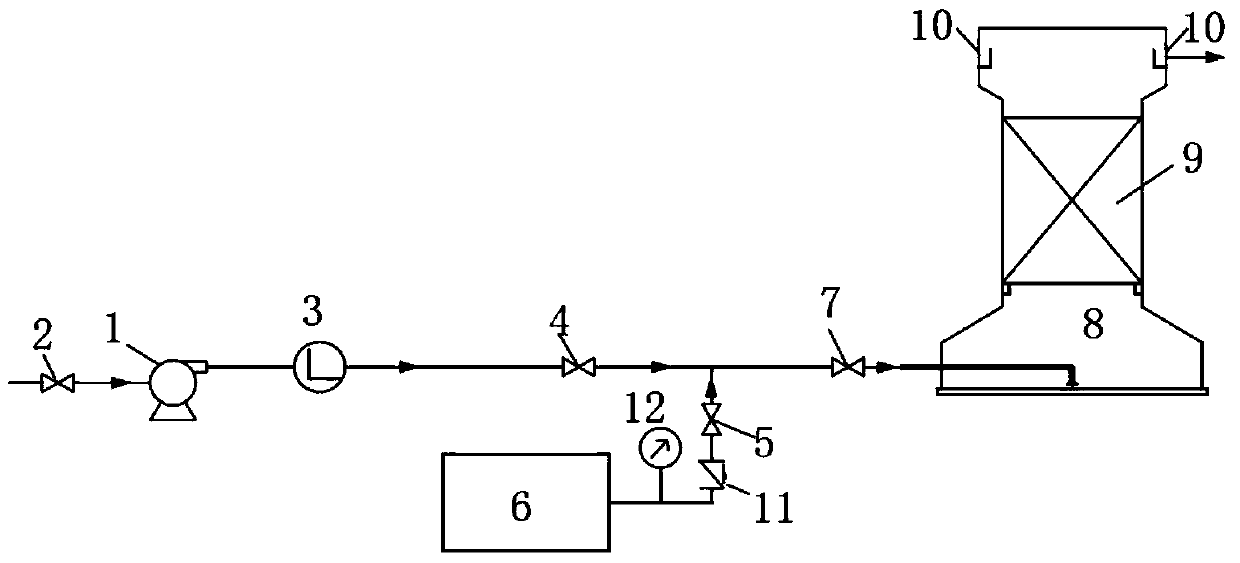

Embodiment 1

[0023]The integrated ozone catalytic oxidation aerated biological filter water treatment device is used for advanced treatment of the secondary biochemical effluent of a printing and dyeing factory. The bottom (ozone catalytic oxidation zone) is filled with ozone catalytic oxidizer, the upper part is covered with ordinary biological ceramsite, and the filter tank is Upflow biological aerated filter. Ozone catalytic oxidant ceramsite is prepared according to Example 4 of 201310268105.0, and the production of ceramsite with a particle size of 6-7mm; ordinary biological ceramsite is obtained by sintering at 900-1200°C by using fly ash, kaolin, and expanding agent as raw materials; The filling height of the catalytic oxidant is about 1m; the filling height of ordinary biological ceramsite is about 2.5m; the water treatment volume in this example is 5t / h, and the mass ratio of ozone dosage to COD is 0.5:1. The reaction time of ozone in the contact oxidation chamber is 2 hours. The ...

Embodiment 2

[0026] The integrated ozone catalytic oxidation-biological aerated filter water treatment method is used for advanced treatment of the secondary biochemical effluent of a paper mill, with a water volume of 10t / h. The bottom (ozone catalytic oxidation zone) is filled with ozone catalytic oxidizer, the upper part is covered with ordinary biological ceramsite, and the filter is an upflow biological aerated filter. The mass ratio of ozone dosing to COD is 0.5:1, and the ozone catalytic oxidant ceramsite is prepared with reference to Example 3 of 201310268105.0 to produce ceramsite with a particle size of 5-6mm; common biological ceramsite uses fly ash, kaolin, and swelling agent as The raw materials are obtained by sintering at 900-1200°C; the filling height of the ozone catalytic oxidant is 0.9m; the filling height of ordinary biological ceramsite is about 2.5m; The treated wastewater enters the biological aerated filter at the upper end of the ozone contact oxidation chamber, th...

Embodiment 3

[0028] The integrated ozone catalytic oxidation-biological aerated filter water treatment method is used to treat the polluted raw water of a waterworks, with a water volume of 10t / h. The bottom (ozone catalytic oxidation zone) is filled with ozone catalytic oxidizer, the upper part is covered with ordinary biological ceramsite, and the filter is an upflow biological aerated filter. The mass ratio of ozone dosage to COD is 0.1:1, and the ozone catalytic oxidant ceramsite is prepared according to Example 4 of 201310268105.0 to produce ceramsite with a particle size of 5-6mm; ordinary biological ceramsite uses fly ash, kaolin, and swelling agent as The raw materials are obtained by sintering at 900-1200°C; the filling height of ozone catalytic oxidizer is 1m; the filling height of ordinary biological ceramsite is 2m; the reaction time of ozone in the contact oxidation chamber is 1 hour. Wastewater enters the biological aerated filter at the upper end of the ozone contact oxidati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com