Green preparation method of levoglucosone having high added value

A L-glucosone, high value-added technology, applied in the preparation of sugar derivatives, chemical instruments and methods, dehydrated sugars, etc., can solve problems such as low yield of L-glucosone, achieve low price, reduce corrosion and pollution, select good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

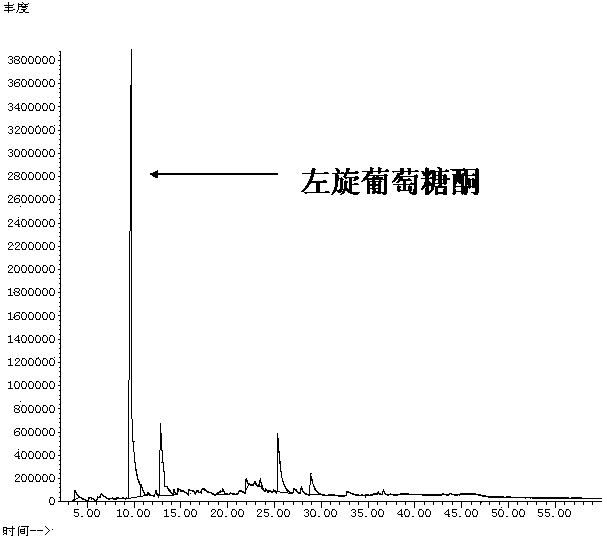

Image

Examples

Embodiment 1

[0027] Mechanically mix 5g of microcrystalline cellulose and 5g of zinc phosphate (mass ratio is 0.01:1) and then pyrolyze it at 200 ℃ under anaerobic conditions. The pyrolysis time is 2 hours. Bio-oil containing L-glucosone, from which L-glucosone is isolated.

Embodiment 2

[0029] Mechanically mix 5g of microcrystalline cellulose and 5g of zinc phosphate (mass ratio is 50:1) and then pyrolyze it at 450°C under anaerobic conditions. The product is condensed and the liquid is collected, which is the bio oil, and then separate out L-glucosone.

Embodiment 3

[0031] Mechanically mix 10g of microcrystalline cellulose and 5g of zinc phosphate (mass ratio: 100:1) and then pyrolyze at 700°C under anaerobic conditions. The pyrolysis time is 2 hours. After the product is condensed, the liquid is collected, which contains The bio-oil of L-glucosone, and then isolate the L-glucosone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com