Large-power conductive chip adhesive

An adhesive and high-power technology, applied in the direction of conductive adhesives, adhesives, adhesive types, etc., can solve the problems of low weight loss and difficulty in increasing the amount of silver added, so as to reduce volatiles, improve reliability, and improve The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

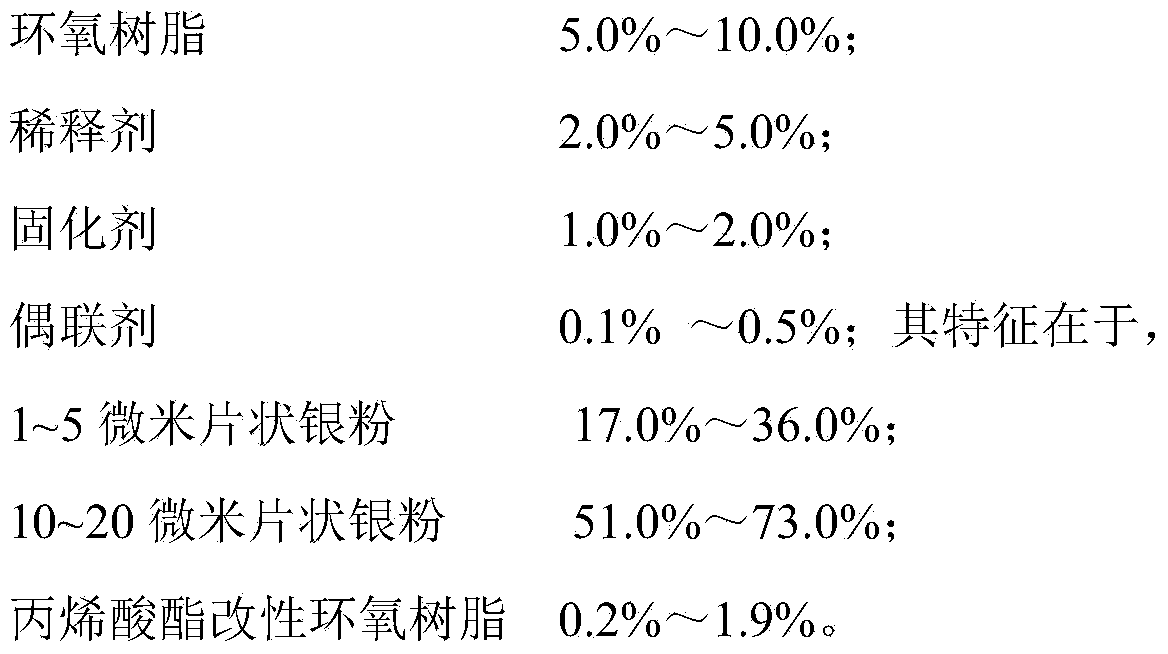

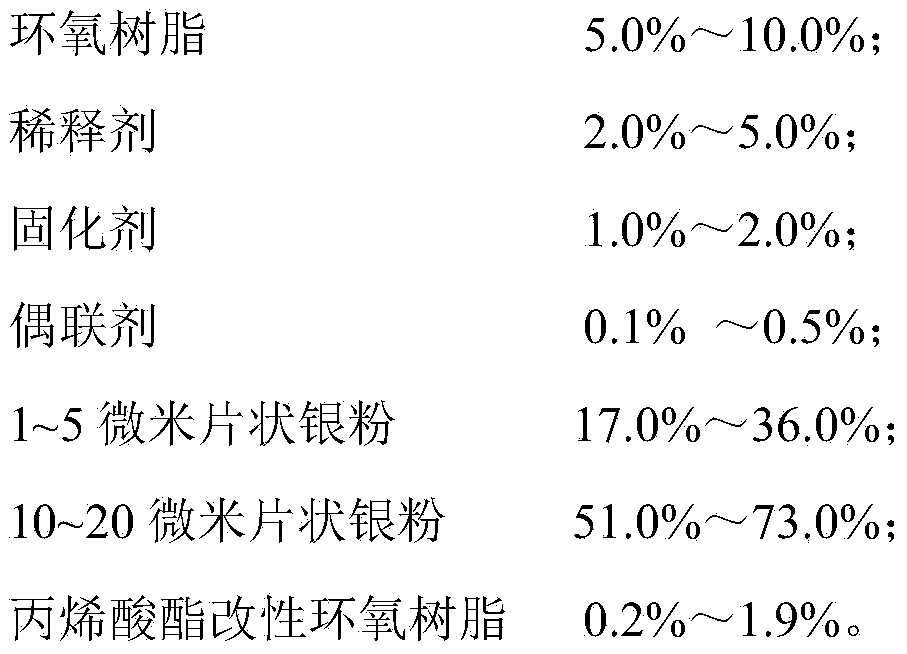

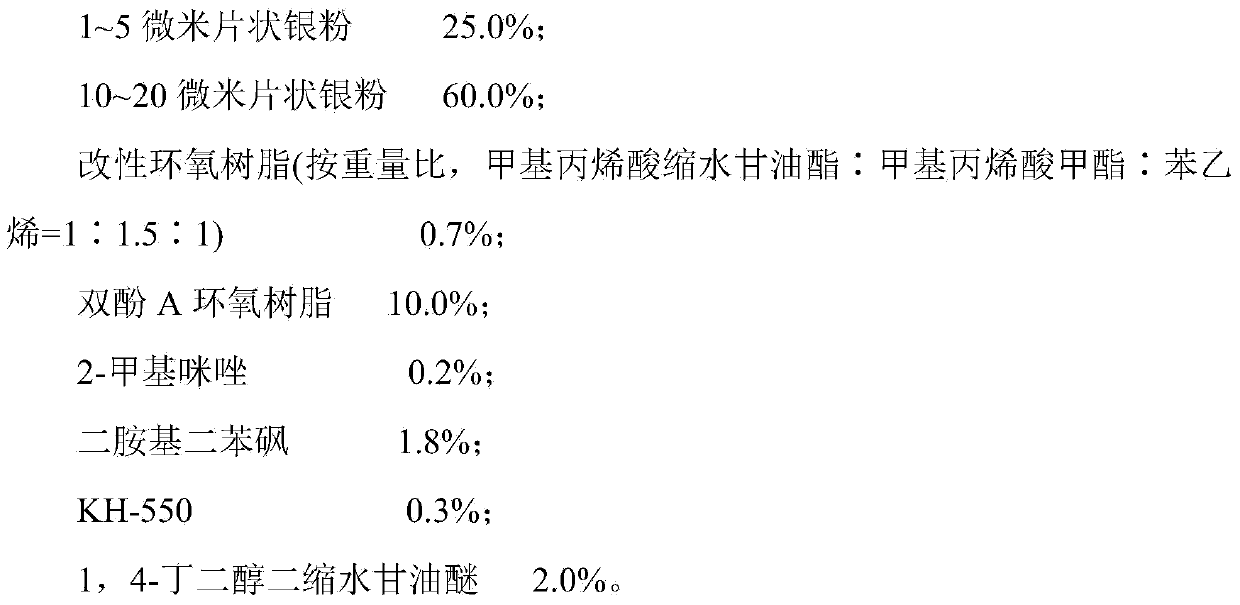

[0026] Components (ingredients) of high-power conductive die-attach:

[0027]

[0028] The preparation method of the above-mentioned high-power conductive chip adhesive is: mix the coupling agent, the curing agent and the diluent evenly according to the above formula ratio, then add epoxy resin and modified epoxy resin to stir, and mix the two silver powders, Slowly add to the liquid, continue to stir until uniform, and finally remove the air bubbles in a vacuum to obtain a conductive adhesive.

[0029] The adhesive viscosity is 9561cps (25°C, 5rpm, Brookfield DV-3), cured at 160°C for 1 hour, the measured horizontal shear force is 20MPa, and the horizontal shear force is 9MPa at 270°C. The volume resistivity is 0.00003ohm cm. The conductivity is 15W / mK, and the curing weight loss is 7.5%.

Embodiment 2

[0031] Components (ingredients) of high-power conductive die-attach:

[0032]

[0033]

[0034] The preparation method of the above-mentioned high-power conductive chip adhesive is: mix the coupling agent, the curing agent and the diluent evenly according to the above formula ratio, then add epoxy resin and modified epoxy resin to stir, and mix the two silver powders, Slowly add to the liquid, continue to stir until uniform, and finally remove the air bubbles in a vacuum to obtain a conductive adhesive.

[0035] The adhesive viscosity is 19233cps (25°C, 5rpm, Brookfield DV-3), cured at 180°C for 1 hour, the measured horizontal shear force at room temperature is 15MPa, the horizontal shear force at 270°C is 5.5MPa, and the volume resistivity is 0.00001ohm· cm, the thermal conductivity is 25W / mK, and the curing weight loss is 5.5%.

Embodiment 3

[0037] Components (ingredients) of high-power conductive die-attach:

[0038]

[0039] The preparation method of the above-mentioned high-power conductive chip adhesive is: mix the coupling agent, the curing agent and the diluent evenly according to the above formula ratio, then add epoxy resin and modified epoxy resin to stir, and mix the two silver powders, Slowly add to the liquid, continue to stir until uniform, and finally remove the air bubbles in a vacuum to obtain a conductive adhesive.

[0040] The adhesive viscosity is 16018cps (25℃, 5rpm, Brookfield DV-3), cured at 150℃ for 1.5 hours, the measured horizontal shear force is 17MPa, the horizontal shear force at 270℃ is 7.5MPa, and the volume resistivity is 0.00001ohm·cm , The thermal conductivity is 21W / mK, and the curing weight loss is 6.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com