High-viscosity high-strength optical transparent organic silicon adhesive and preparation method thereof

A high-strength, silicone technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of low viscosity, poor adhesion, low strength, etc., and achieve high light transmittance , High adhesion, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The present invention is a high-viscosity and high-strength optical transparent silicone adhesive, which is composed of component A and component B with a weight ratio of 1:1, wherein,

[0065] The A component is composed of the following raw materials in parts by weight: double-capped vinyl polysiloxane with a viscosity of 100,000 centipoise such as structural formula (1) with a vinyl content of 0.04wt%, 10.00 g; a viscosity of 200 centipoise Double-capped vinyl polysiloxane such as structural formula (1), vinyl content 0.6wt%, 60.00g; vinyl MQ resin, such as molecular formula (1), viscosity 500 centipoise, vinyl content 5wt%, 27.85g ;

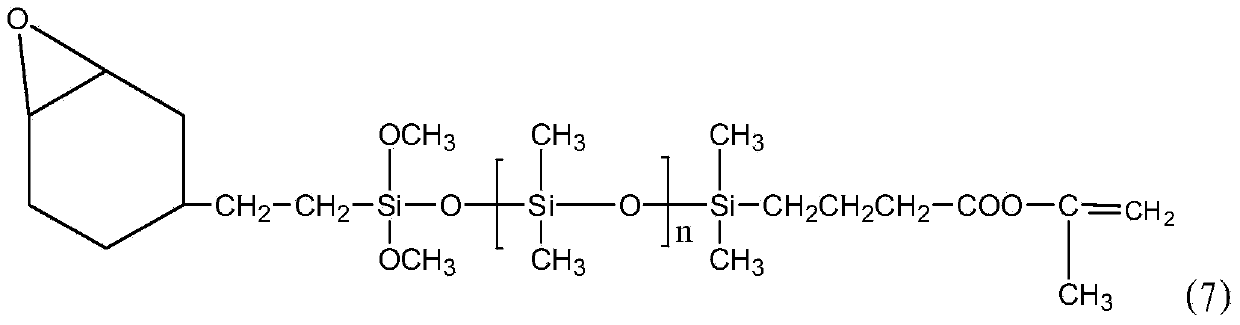

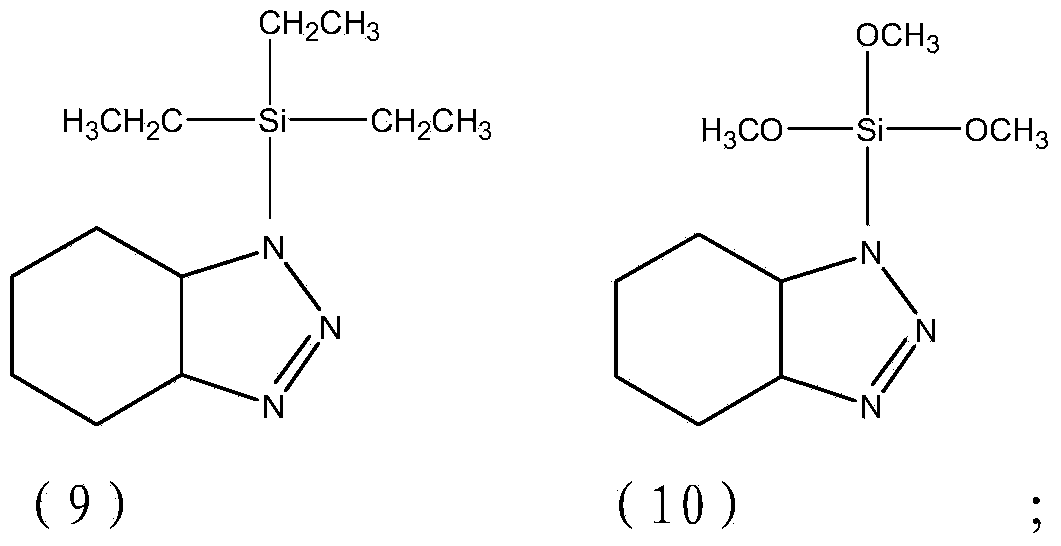

[0066] Viscosity promoter such as structural formula (7), 0.05g; flame retardant such as structural formula (9), 2.00g; catalyst platinum (0)-2,4,6,8-tetramethyl-2,4,6,8- Tetravinylcyclotetrasiloxane complex solution 0.10g, content 7000ppm;

[0067] The B component is composed of the following raw materials in parts by weight: double...

Embodiment 2

[0073] A high-viscosity and high-strength optical transparent silicone adhesive, which consists of component A and component B with a weight ratio of 1:1, wherein,

[0074] The A component consists of the following raw materials in parts by weight:

[0075] The base material is a double-blocked vinyl polysiloxane with a viscosity of 20,000 centipoise such as structural formula (1) with a vinyl content of 0.08wt%, 15.10 g; a double-blocked vinyl polysiloxane with a viscosity of 6,000 centipoise such as Structural formula (1) vinyl content 0.11wt%, 50.00g; vinyl MQ resin, such as molecular formula (1), viscosity 5000 centipoise, vinyl content 2wt%, 27.85g;

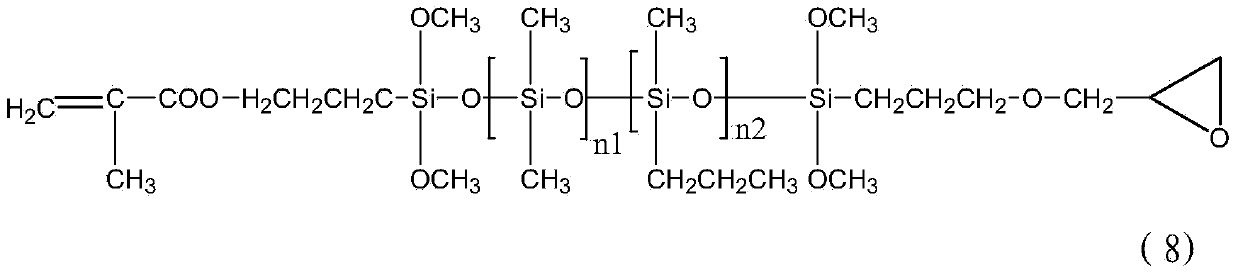

[0076] Viscosity promoter such as structural formula (8) 5.00g; Flame retardant such as structural formula (10) 0.05g; Catalyst is platinum (0)-2,4,6,8-tetramethyl-2,4,6,8-tetra Vinylcyclotetrasiloxane complex solution 2.00g, content 2000ppm;

[0077] The B component consists of the following raw materials in parts by weig...

Embodiment 3

[0084] A high-viscosity and high-strength optical transparent silicone adhesive, which consists of component A and component B with a weight ratio of 1:1, wherein,

[0085] The A component consists of the following raw materials in parts by weight:

[0086] A base material with a viscosity of 50,000 centipoise of double-blocked vinyl polysiloxane such as structural formula (1) with a vinyl content of 0.05 wt%, 25.50 g; a viscosity of double-blocked vinyl polysiloxane of 1,000 centipoise such as structural formula (1) Vinyl content is 0.4wt%, 50.00g; vinyl MQ resin, such as molecular formula (1), viscosity is 7000 centipoise, vinyl content is 1.5wt%, 20.00g;

[0087] Viscosity promoter such as structural formula (8) 3.00g; Flame retardant such as structural formula (10) 0.50g; Catalyst is platinum (0)-2,4,6,8-tetramethyl-2,4,6,8-tetra Vinylcyclotetrasiloxane complex solution 1.00g, content 5000ppm.

[0088] The B component consists of the following raw materials in parts by w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com