Glass antifogging agent specially used for automobiles and preparation method of the antifogging agent

An anti-fogging agent, glass technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of short anti-fog time, high risk, high cost, etc., to prevent condensation of small water droplets, easy to carry, safe to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

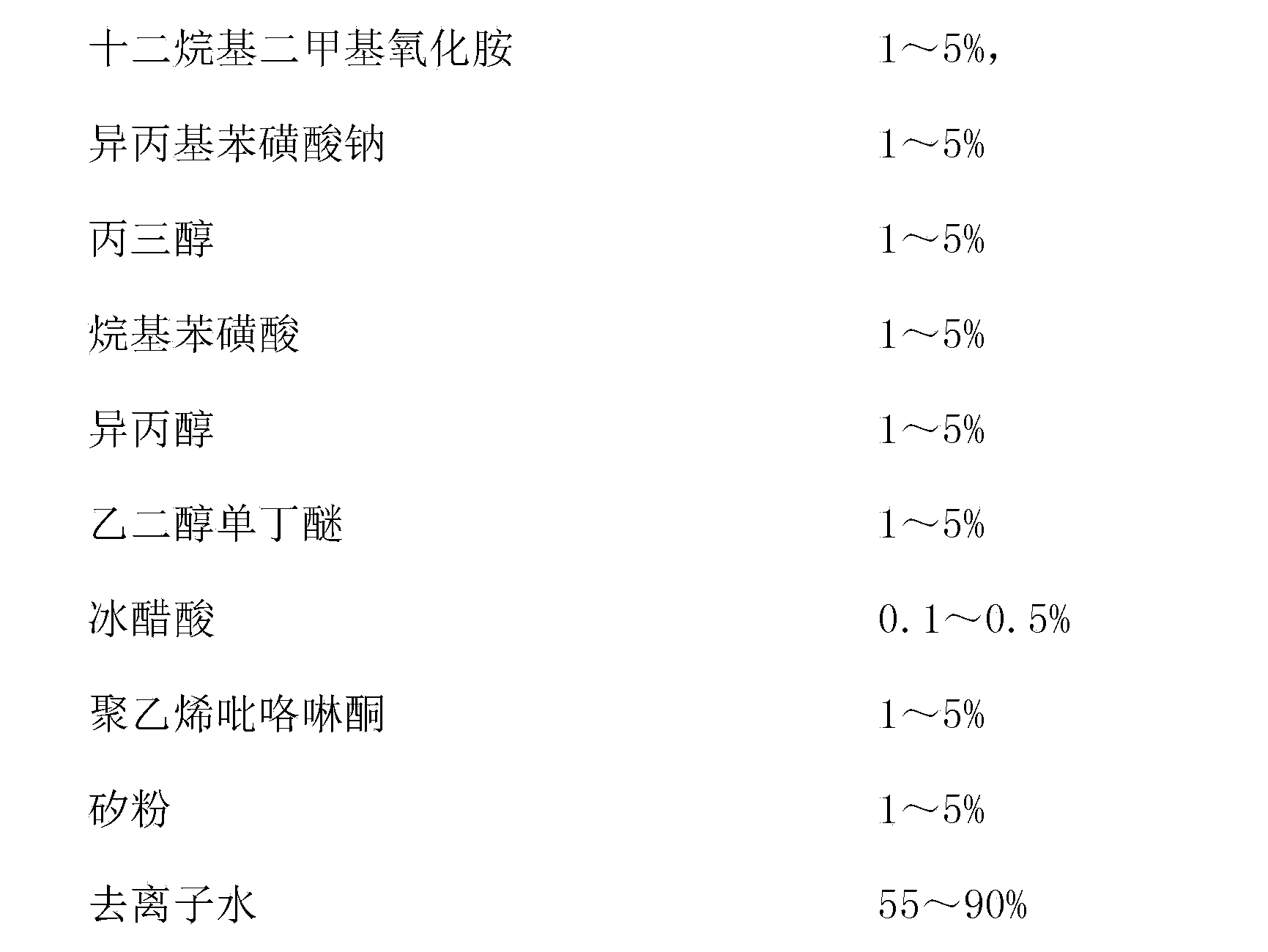

Embodiment 1

[0014] The formula mass ratio of the antifogging agent for automobile special glass of the present invention is: dodecyl dimethyl amine oxide 3%, sodium cumene sulfonate: 3%, glycerol: 3%, alkylbenzene sulfonate Acid: 3%, isopropyl alcohol: 3%, ethylene glycol monobutyl ether: 3%, glacial acetic acid 0.3%, polyvinylpyrrolidone: 3%, silicon powder: 3%, deionized water: 73%. , The specific preparation steps of the antifogging agent for glass for automobiles are as follows: (1) at room temperature and normal pressure, 3 mg of silicon powder, 3 mL of dodecyl dimethylamine oxide, 3 mL of glycerol, and cumene Mix 3mg of sodium sulfonate with 0.3mL of glacial acetic acid and shake well to obtain solution A; (2) Mix 3mL of alkylbenzenesulfonic acid, 3mL of isopropanol, 3mL of deionized water, 0.3mL of glacial acetic acid and polyvinylpyrrolidone 3mL was mixed to obtain B solution; (3) under stirring, slowly add the B solution prepared in (2) to the A solution prepared in (1) for hydro...

Embodiment 2

[0016] The formula mass ratio of the antifogging agent for automobile special glass of the present invention is: dodecyl dimethyl amine oxide 5%, sodium cumene sulfonate: 3%, glycerol: 5%, alkylbenzene sulfonate Acid: 3%, isopropanol: 5%, ethylene glycol monobutyl ether: 3%, glacial acetic acid 0.3%, polyvinylpyrrolidone: 5%, silicon powder: 3%, deionized water: 65%. Described preparation method is identical with example 1.

Embodiment 3

[0018] The formula mass ratio of the antifogging agent for automobile special glass of the present invention is: dodecyl dimethyl amine oxide 5%, sodium cumene sulfonate: 5%, glycerol: 5%, alkylbenzene sulfonate Acid: 5%, isopropanol: 5%, ethylene glycol monobutyl ether: 3%, glacial acetic acid 0.3%, polyvinylpyrrolidone: 3%, silicon powder: 3%, deionized water: 63%. Described preparation method is identical with example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com