New high-speed spinning machine

A spinning machine, high-speed technology, applied in the field of new high-speed spinning machines, can solve the problems of water and acid solution pollution, complex structure of the whole machine, and high energy consumption of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

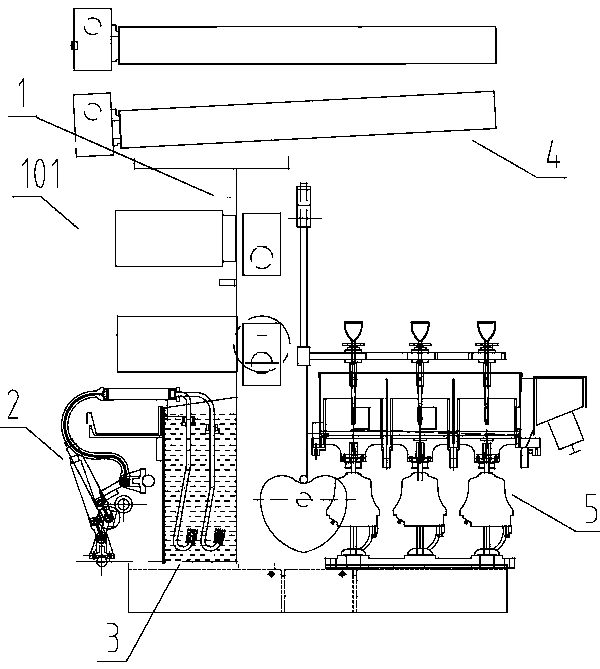

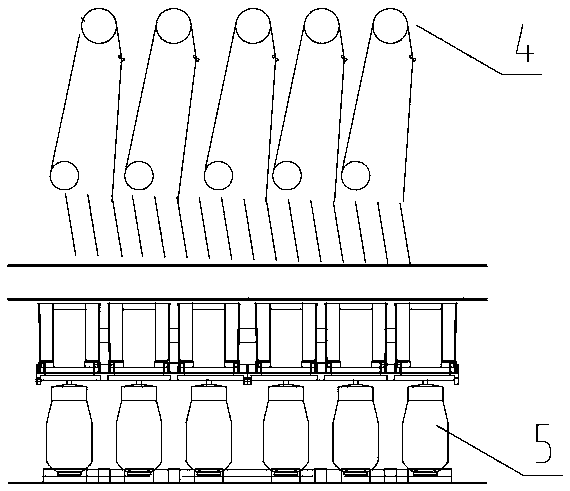

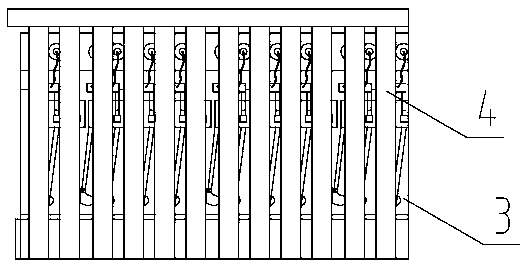

[0255] The spinning machine includes a frame 1, a glue supply device 2, a filament forming device 3, a spinning device 4 and a winding device 5, and the forming part of the winding device 5 is located between the wall panels 6 on both sides of the frame 1. The outer side of the area, the other side opposite to the spinning surface 101, the forming part of the winding device 5 includes the loose bobbin tube 5203 of the winding device 5 or a structure having the same function as the loose bobbin tube 5203; the spinning surface 101 Refers to the area outside the wallboard 6 of the frame 1 where the thread forming device 3 is provided, and the other side opposite to the area provided with the thread forming device 3 is called the winding surface 7 .

[0256] The spinning device 4 includes at least one group of spinning rolls, each group of spinning rolls includes an upper spinning roll 401 and a lower spinning roll 402 responsible for drafting, the two ends of the upper spinning ro...

Embodiment 2

[0262] The spinning machine includes a frame 1, a glue supply device 2, a filament forming device 3, a spinning device 4 and a winding device 5, and the forming part of the winding device 5 is located between the wall panels 6 on both sides of the frame 1. The outer side of the area, the other side opposite to the spinning surface 101, the forming part of the winding device 5 includes the loose bobbin tube 5203 of the winding device 5 or a structure having the same function as the loose bobbin tube 5203; the spinning surface 101 Refers to the area outside the wallboard 6 of the frame 1 where the thread forming device 3 is provided, and the other side opposite to the area provided with the thread forming device 3 is called the winding surface 7 . The spinning device 4 includes at least one group of spinning rolls, each group of spinning rolls includes an upper spinning roll 401 and a lower spinning roll 402 responsible for drafting, the upper spinning roll 401 and the lower spin...

Embodiment 3

[0267] A step 405 is provided at the front of the upper spinning roll 401 , and the diameter of the step 405 is smaller than that of the rest of the upper spinning roll 401 . The washing device 41 is located in the middle section of the spinning roll. The water washing device 41 is 1 road.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com