LED (light emitting diode) epitaxy structure and application thereof

An epitaxial structure and light-emitting layer technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing luminous efficiency and forward voltage, and achieve high luminous efficiency, reduce negative effects, and improve the effect of lattice quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

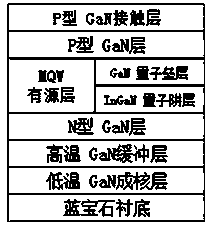

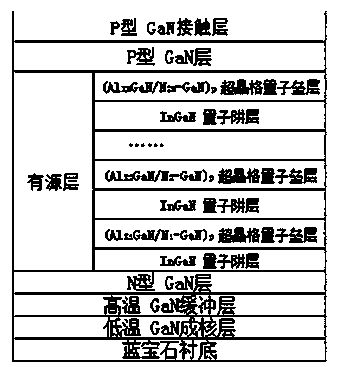

[0026] Conventional LED epitaxial structures such as figure 1 As shown, the structure of this embodiment is as figure 2 As shown, specifically, the GaN nucleation layer, the GaN buffer layer, the n-type GaN layer, the MQW light-emitting layer with 15 pairs of repeated periods, and the p-type GaN layer and p-type contact layer are grown sequentially on the sapphire substrate by MOCVD method. . The number of pairs of AlGaN / n-GaN superlattice quantum barrier layers in each pair of MQW light-emitting layers is 5 pairs, 5 pairs of superlattice quantum barrier layers have the same Al composition content and the same n-type doping concentration value, and 15 pairs The total thickness of the MQW light-emitting layer with superlattice quantum barriers is 225nm, of which the total thickness of quantum well layers is 45nm, the total thickness of superlattice quantum barrier layers is 180nm, and the total thickness of each pair of AlGaN / n-GaN superlattice quantum barrier layers is 12nm...

Embodiment 2

[0031]Different from the optimization scheme of the exponential gradient mode for the Al component and n-type impurity concentration proportional coefficient in Example 1, this embodiment adopts the stepwise linear increase and then linear decrease of the Al component and n-type impurity concentration proportional coefficient.

[0032] Each MQW light-emitting layer group is composed of several pairs of MQW light-emitting layer pairs with the same characteristics of AlGaN / n-GaN superlattice quantum barrier layers, and Al(m) represents the AlGaN / n-GaN superlattice in the mth group of MQW light-emitting layer The Al composition value in the quantum barrier layer pair, N(m) represents the n-type impurity concentration value in the AlGaN / n-GaN superlattice quantum barrier layer pair in the m-th group of MQW light-emitting layers, from the first pair of MQW light-emitting layers to the first For the MQW light-emitting layer, the change trend of the Al (m) is linearly increasing, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com