High-power and low-divergence semiconductor terahertz vertical surface-emitting laser

A technology of vertical surface emission and low divergence angle, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of asymmetric far-field divergence angle of size, unfavorable large-scale production of devices, complex structure and process production, etc., to achieve strong Experimental operability, improvement of far-field divergence angle, and effect of increasing surface emission output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

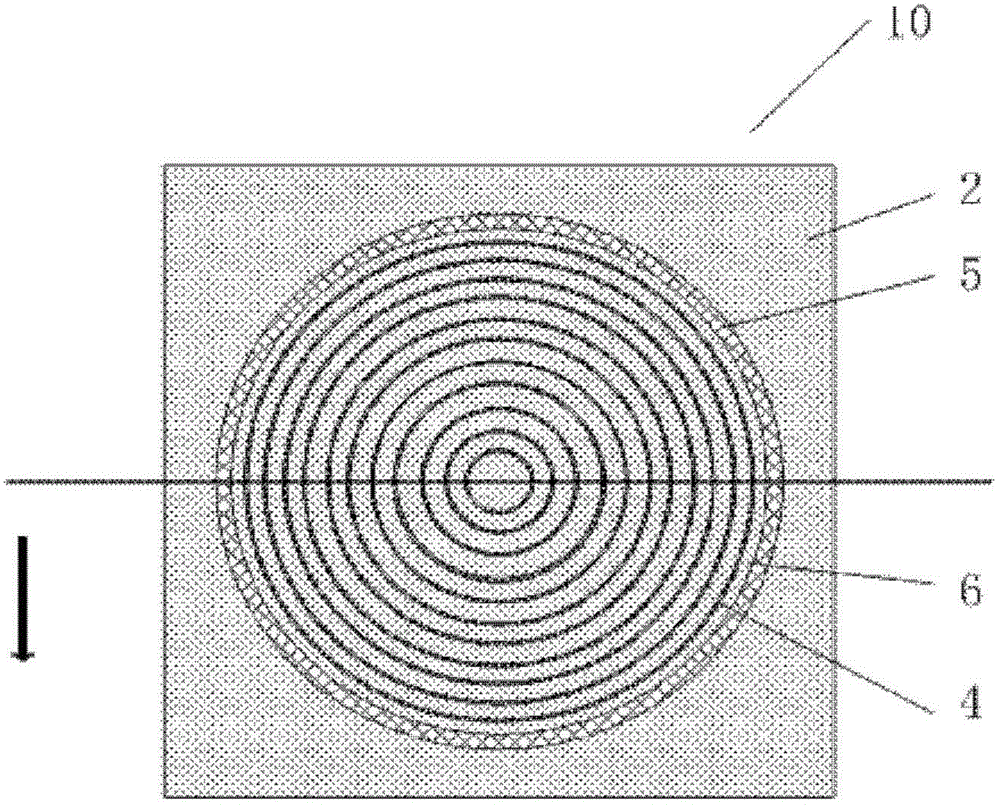

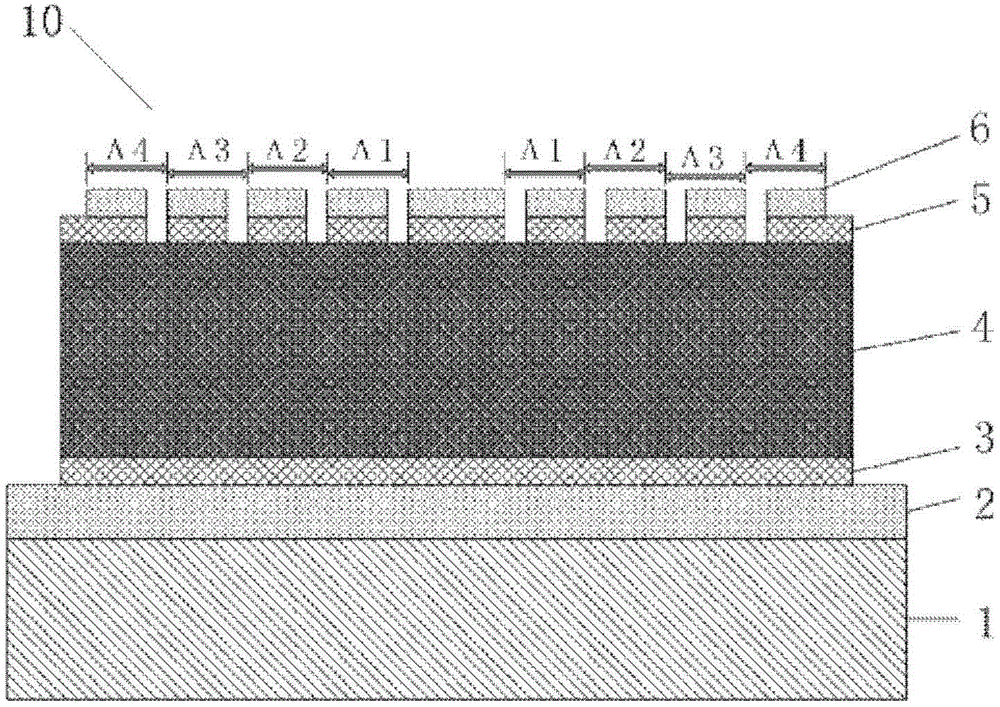

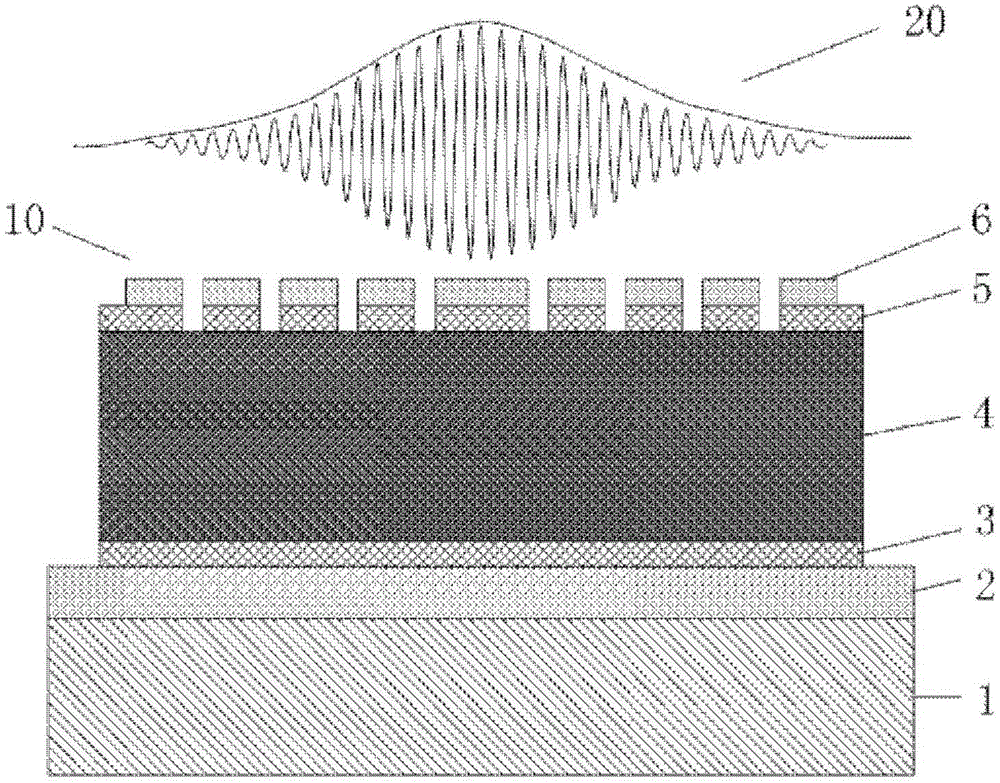

[0020] see figure 1 and figure 2 As shown, the present invention provides a semiconductor terahertz vertical surface-emitting laser 10 with high power and low divergence angle, including:

[0021] A highly doped receiving substrate 1, the highly doped receiving substrate 1 is an n-type doped GaAs substrate with a doping concentration of 1×10 18 -2×10 18 cm -3 , the substrate is used for metal thermal bonding with the epitaxial wafer;

[0022] The lower metal waveguide light confinement layer 2 is formed by metal thermal bonding and is located on the receiving substrate 1. The material of the lower metal waveguide light confinement layer 2 is In—Au, which It is prepared by double-sided metal waveguide In / Au thermal bonding process;

[0023] The lower contact layer 3 is located on the lower metal waveguide light confinement layer 2, the lower contact layer 3 is n-type doped GaAs grown by MBE method, and the doping concentration is 2×10 18 cm -3 , with a thickness of 0.2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com