VCSEL chip and manufacturing method thereof

A manufacturing method and chip technology, applied in laser parts, electrical components, lasers, etc., can solve problems such as poor beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0049] For the VCSEL chip that emits light at a wavelength of 940nm, a three-quantum well structure is used, and the DBR is a periodic material composed of GaAs with a quarter optical thickness and Al0.90GaAs with a quarter optical thickness. P-DBR (that is, p Type DBR layer 13) has 16 pairs of pairs, and N-DBR (that is, n-type DBR layer 11) has 38 pairs of pairs. Wherein, the material composition of the optical absorption layer 18 is In(x)GaAs, where x=0.12, the thickness is 66 nm, the diameter of the mesa 16 is 35 μm, the inner diameter of the optical absorption layer 18 is 5 μm, and the pore diameter of the oxide ring 17 is 10 μm.

example 2

[0051] For the VCSEL chip with a wavelength of 940nm for emitting light, the composition of the material of the optical absorption layer 18 is In(x)GaAs, where x=0.11, and the thickness range is 32-96nm, corresponding to λ / (8n)-3λ / (8n ), where n is the material refractive index of the absorbing layer material In0.11GaAs at a wavelength of 940, which is approximately equal to 3.65.

example 3

[0053] For the VCSEL chip with a wavelength of 905nm for emitting light, the composition of the material of the optical absorption layer 18 is In(x)GaAs, where x needs to be greater than 0.055 to ensure that the band gap of the In(x)GaAs material is smaller than the photon corresponding to the wavelength of 905nm energy. In this example, take x=0.06, the thickness of the optical absorption layer 18 is 31-93nm, corresponding to λ / (8n)-3λ / (8n), where n is the absorption layer material In0.06GaAs at wavelength 905 The refractive index of the material, approximately equal to 3.66.

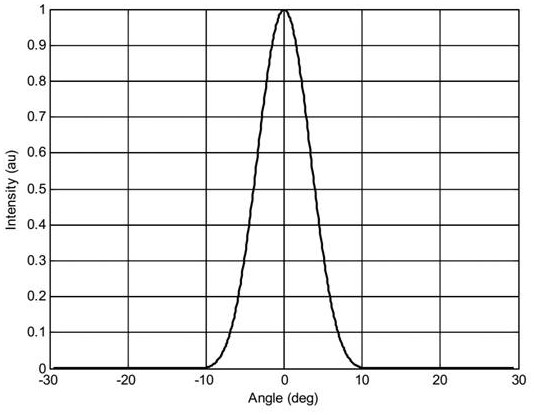

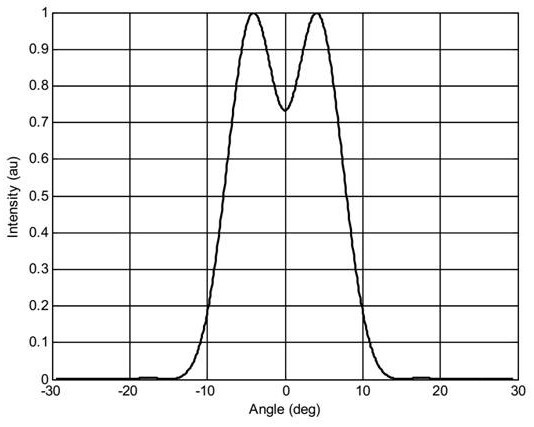

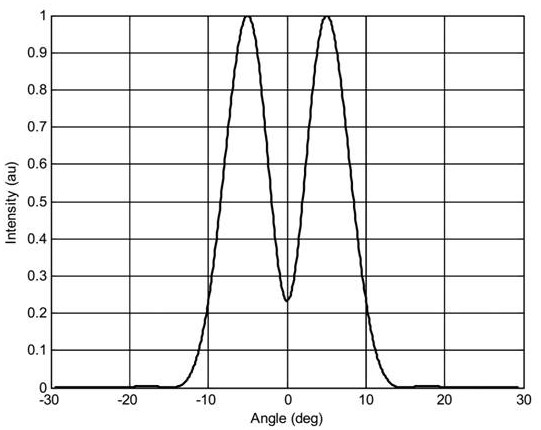

[0054] In addition, in order to further illustrate the suppression effect of the optical absorption layer 18 on high-order modes, the threshold current and light output power of the VCSEL chip in different situations were calculated, and the results are shown in Table 1. The calculation example in Table 1 is for a VCSEL with a wavelength of emitted light of 940nm For the chip, the pore diameter of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com