Tooth desensitizer as well as preparation method and application thereof

A desensitizer and tooth technology, applied in the field of tooth desensitizers, can solve the problems of inaccessibility of bioactive glass, mutual fusion, no dentin hypersensitivity, etc., and achieve excellent biocompatibility, broad market prospects, prevention and treatment of oral diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Preparation of mesoporous silica nanoparticles

[0045] The ratio of raw materials is cetyltrimethylammonium bromide (CTAB): deionized water: sodium hydroxide: tetraethyl orthosilicate (TEOS) = 1: 8504: 2.55: 8.13 (molar ratio); Mix cetyltrimethylammonium bromide, deionized water and sodium hydroxide, stir the reaction system at 70°C until the temperature is stable, and after the cetyltrimethylammonium bromide is completely dissolved, add n- Ethyl silicate; the reaction system was kept at 70°C for 2 hours. After the reaction, the white solid was obtained by suction filtration and dried in an oven at 50°C for 10 hours; the obtained white powder sample was ground with a mortar and put into a crucible , calcined in a muffle furnace at 550°C for 4 hours to remove the template agent CTAB; the calcined sample was ground again to obtain mesoporous silica nanoparticles with ordered pores, the pore volume was 0.84cm3 / g, and the pore diameter was 3.0 nm;

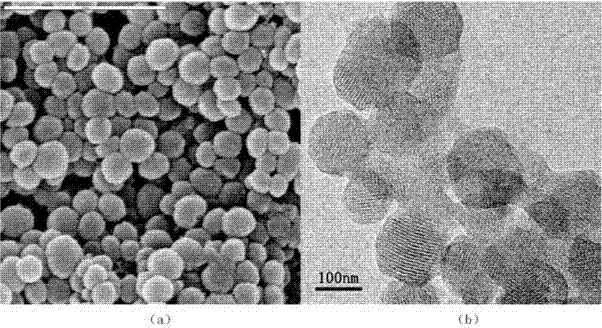

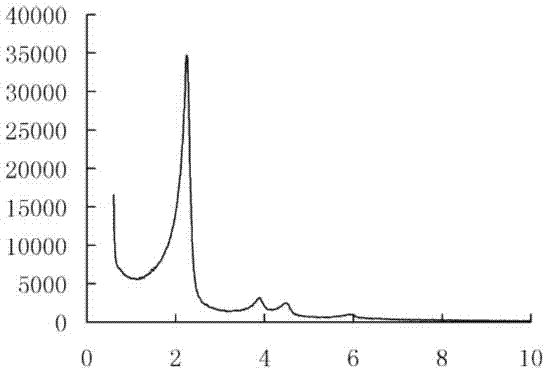

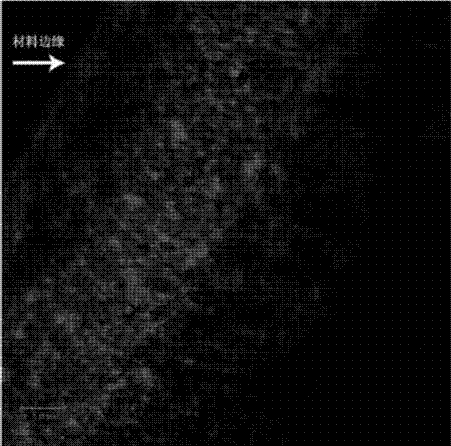

[0046] The scanni...

Embodiment 2

[0062] (1) Preparation of mesoporous silica nanoparticles

[0063] The ratio of raw materials is cetyltrimethylammonium bromide (CTAB): deionized water: sodium hydroxide: tetraethyl orthosilicate (TEOS) = 1: 4859: 2: 8.13 (molar ratio); according to the above formula Mix cetyltrimethylammonium bromide, deionized water and sodium hydroxide, stir the reaction system at 70°C until the temperature is stable, and after the cetyltrimethylammonium bromide is completely dissolved, add n- Ethyl silicate; the reaction system was kept at 70°C for 2 hours. After the reaction, the white solid was obtained by suction filtration and dried in an oven at 50°C for 10 hours; the obtained white powder sample was ground with a mortar and put into a crucible , calcined in a muffle furnace at 550°C for 4 hours to remove the template agent CTAB; the calcined sample was ground again to obtain mesoporous silica nanoparticles with ordered pores, the pore volume was 0.89cm3 / g, and the pore diameter was 3...

Embodiment 3

[0072] (1) Preparation of mesoporous silica nanoparticles

[0073] The ratio of raw materials is cetyltrimethylammonium bromide (CTAB): deionized water: sodium hydroxide: tetraethyl orthosilicate (TEOS) = 1: 9719: 2.55: 8.13 (molar ratio); Mix cetyltrimethylammonium bromide, deionized water and sodium hydroxide, stir the reaction system at 70°C until the temperature is stable, and after the cetyltrimethylammonium bromide is completely dissolved, add n- Ethyl silicate; the reaction system was kept at 70°C for 2 hours. After the reaction, the white solid was obtained by suction filtration and dried in an oven at 50°C for 10 hours; the obtained white powder sample was ground with a mortar and put into a crucible , calcined in a muffle furnace at 550°C for 4 hours to remove the template agent CTAB; the calcined sample was ground again to obtain mesoporous silica nanoparticles with ordered pores, and the pore volume was 0.81 cm 3 / g, the pore diameter is 3.0nm;

[0074] The scann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com