Tristyrene nitrile derivative as well as preparation method and application thereof

A technology for tristyryl nitrile and derivatives, which is applied to tristyryl nitrile derivatives and the fields of preparation and application thereof, can solve the problems of low reversible temperature, limited application, harmful to health, etc., and achieves simple preparation process, convenient preparation of devices, high contrast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

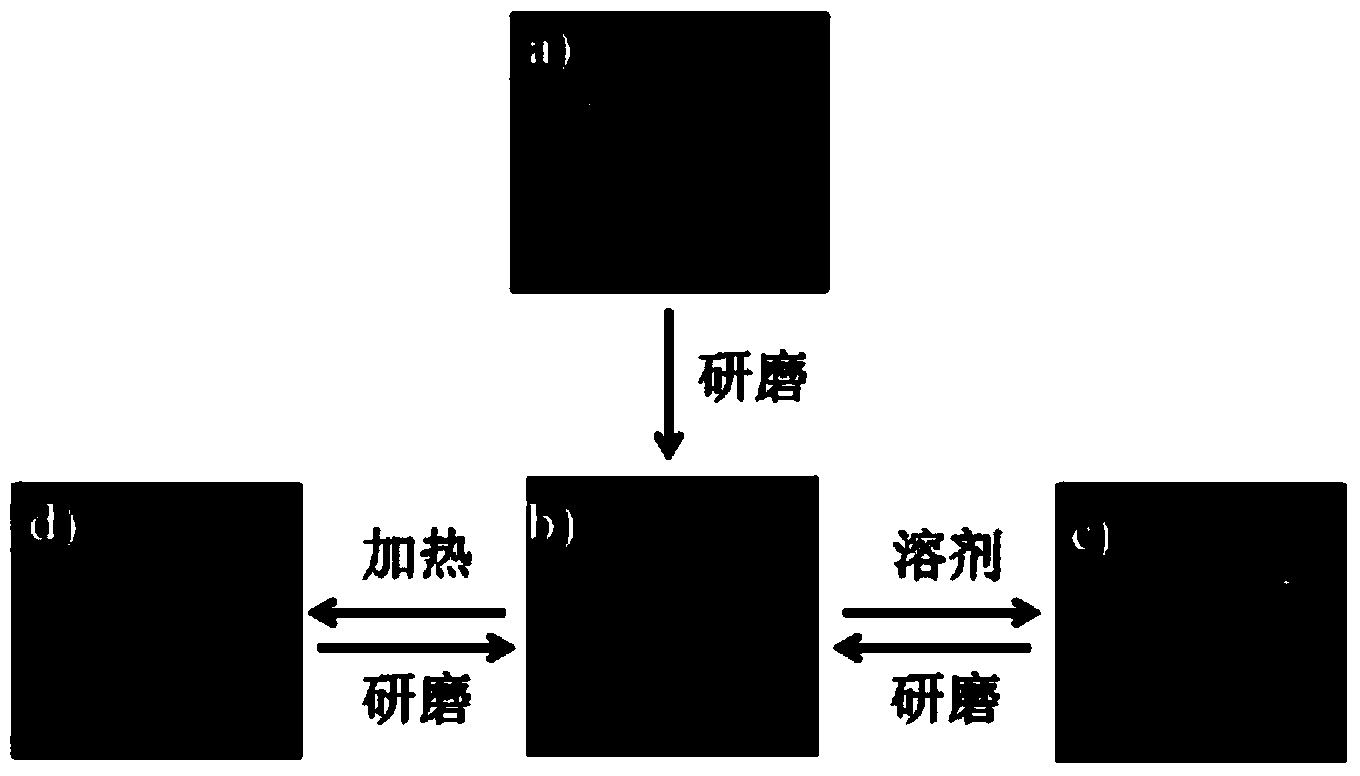

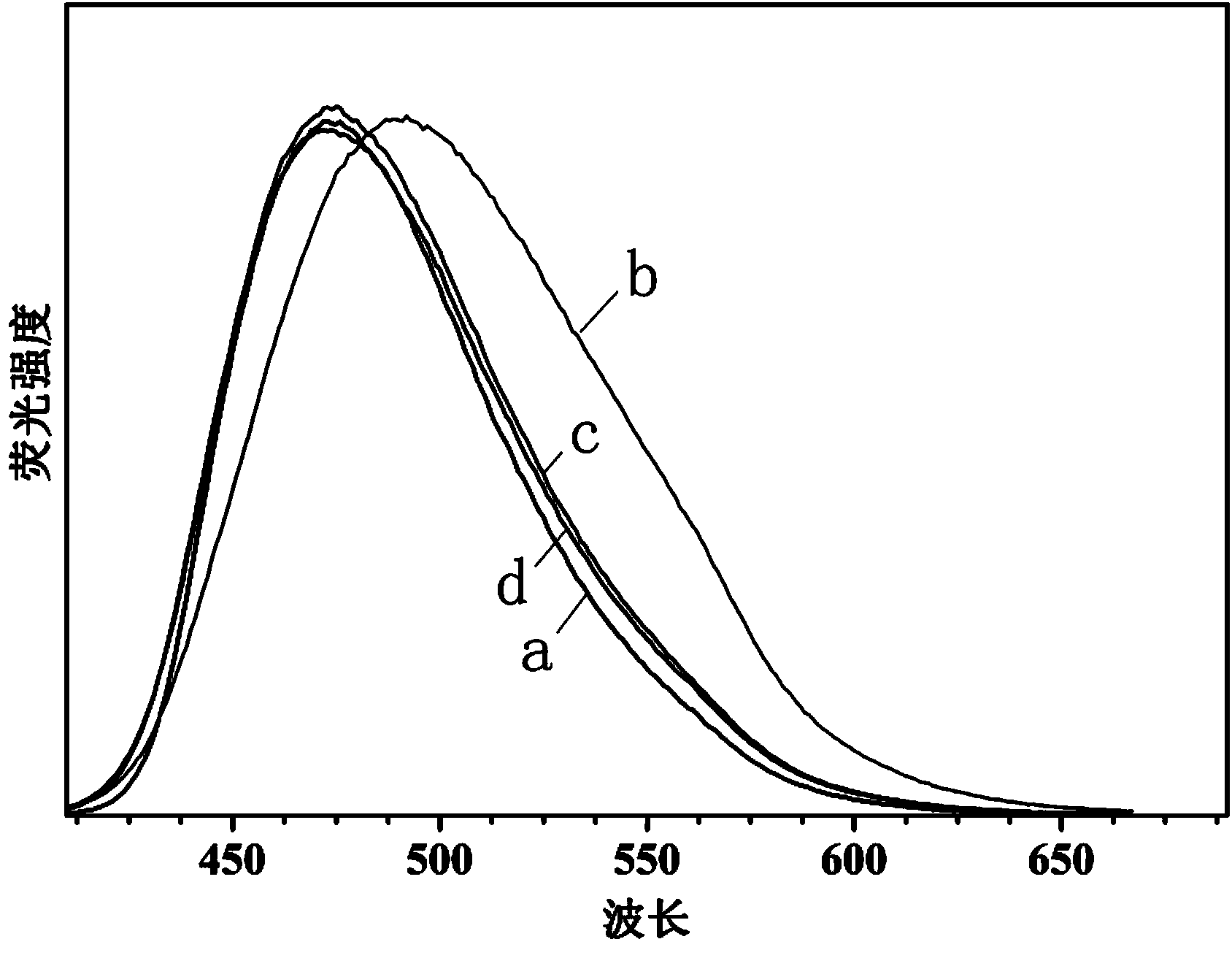

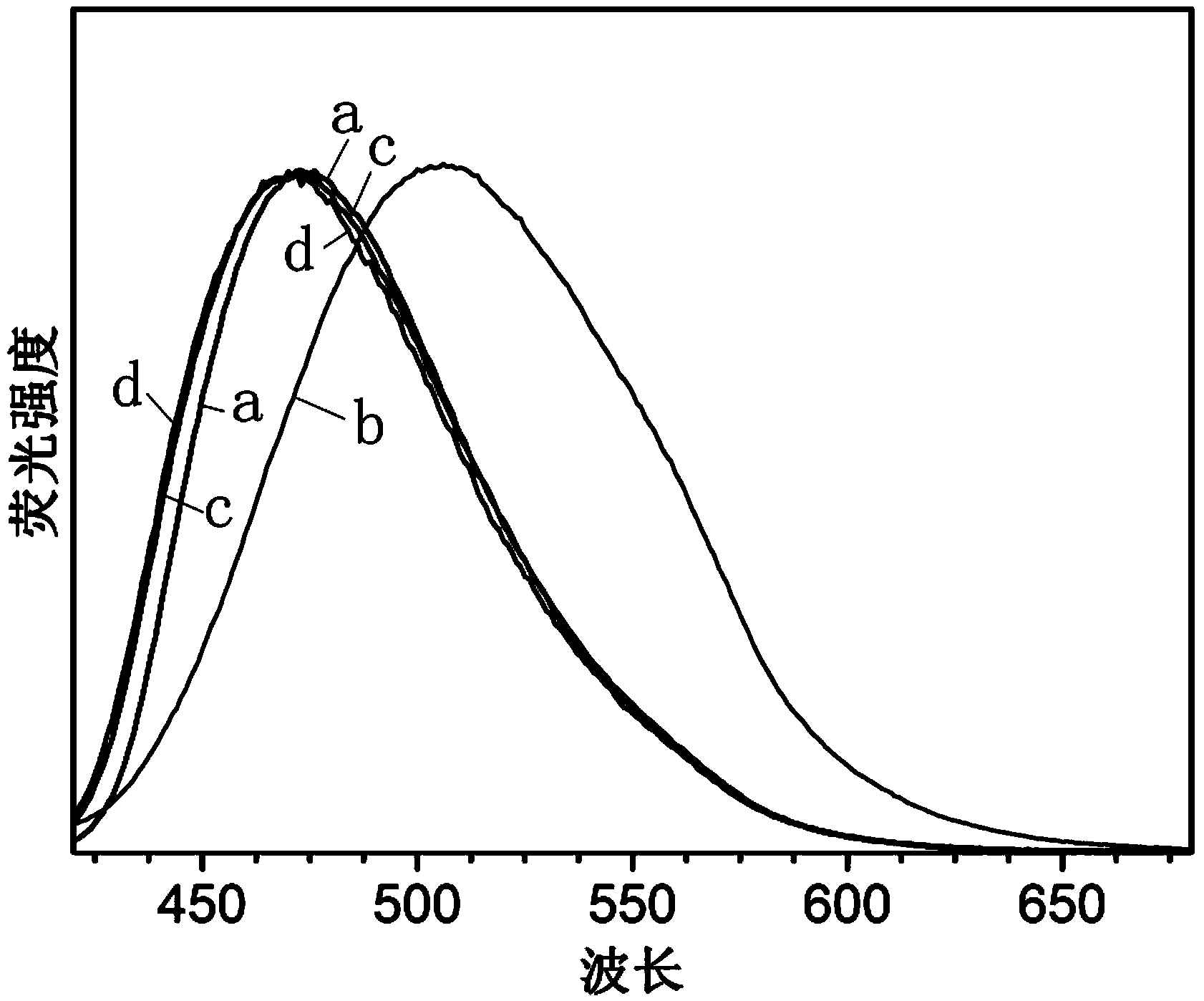

Method used

Image

Examples

Embodiment 1

[0035] 2-(4-bromophenyl)-3,3-diphenylacrylonitrile 1.2g (6mmol), tetrakistriphenylphosphine palladium 0.03g (0.03mmol), p-methoxyphenylboronic acid 1.47g (12mmol), carbonic acid Sodium aqueous solution (2.0M, 1.8mL) was dissolved in 50mL of toluene, reacted at 90°C for 24h under the protection of high-purity nitrogen, after the reaction was completed, cooled, separated the organic phase, extracted with dichloromethane, combined the organic phase, and washed three times with saturated brine , dried over anhydrous sodium sulfate, left standing overnight, filtered, and the concentrated crude product was separated by column chromatography [V (petroleum ether) / V (ethyl acetate)=50 / 1] to obtain the target product 1.08g, the yield was 65.7%. 1 H NMR (500MHz, CDCl 3 )δ7.53(d,J=8.8Hz,2H),7.51-7.47(m,2H),7.48-7.42(m,5H),7.34(d,J=8.4Hz,2H),7.30(t,J =7.3Hz,1H),7.24(t,J=7.4Hz,2H),7.09(d,J=7.2Hz,2H),6.99(d,J=8.8Hz,2H),3.87(s,3H). 13 C NMR (125MHz, CDCl 3 )δ159.47,157.33,140.54,140.52,13...

Embodiment 2

[0037] 2-(4-bromophenyl)-3,3-diphenylacrylonitrile 2.0g (10mmol), tetrakistriphenylphosphine palladium 0.05g (0.05mmol), p-methoxyphenylboronic acid 3.05g (25mmol), carbonic acid Sodium aqueous solution (2.0M, 3.0mL) was dissolved in 60mL of toluene, reacted at 90°C for 24h under the protection of high-purity nitrogen, after the reaction was completed, cooled, separated the organic phase, extracted with dichloromethane, combined the organic phase, and washed three times with saturated brine , dried over anhydrous sodium sulfate, left to stand overnight, filtered, and the concentrated crude product was separated by column chromatography [V (petroleum ether) / V (ethyl acetate)=50 / 1] to obtain 1.92 g of the target product, the yield 70%.

Embodiment 3

[0039] 2-(4-bromophenyl)-3,3-diphenylacrylonitrile 3.0g (15mmol), tetrakistriphenylphosphine palladium 0.075g (0.075mmol), p-methoxyphenylboronic acid 4.5g (37mmol), carbonic acid Sodium aqueous solution (2.0M, 4.0mL) was dissolved in 80mL of toluene, and reacted at 90°C for 24h under the protection of high-purity nitrogen. After the reaction was completed, cooled, separated the organic phase, extracted with dichloromethane, combined the organic phase, and washed three times with saturated brine , dried over anhydrous sodium sulfate, left to stand overnight, filtered, and the concentrated crude product was separated by column chromatography [V (petroleum ether) / V (ethyl acetate)=50 / 1] to obtain 2.79 g of the target product, the yield 68%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com