Metal organic frame/graphene carried palladium nano-composite catalyst and preparing method and application thereof

A metal-organic framework and composite catalyst technology, applied in the field of catalysis, to achieve the effects of simple preparation process, easy industrialization, and excellent carrier characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

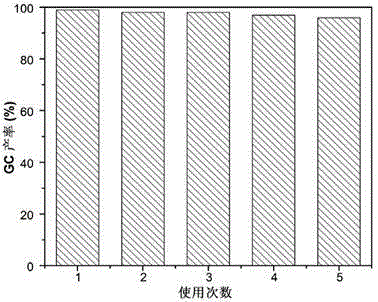

Examples

Embodiment 1

[0019] (1) Preparation method of graphene oxide:

[0020] Take graphite powder and sodium nitrate, add concentrated sulfuric acid and stir evenly, then put it in an ice bath, add potassium permanganate while stirring, keep the temperature below 20℃, then heat up to 35℃ and keep it for 1~2h, add slowly Ionized water, the volume ratio of the added deionized water and concentrated sulfuric acid is 2:1, and the temperature is increased to 85~95℃, kept for 15min, then add 10mL30% hydrogen peroxide and deionized water, the deionized water added at this time The volume ratio of water to concentrated sulfuric acid is 6:1. The resulting product is centrifuged, washed with dilute hydrochloric acid, dried, and ground to obtain graphene oxide; the mass ratio of graphite powder to sodium nitrate is 2:1, concentrated sulfuric acid to graphite The powder ratio is 23mL / mg, and the mass ratio of potassium permanganate to graphite powder is 3:1.

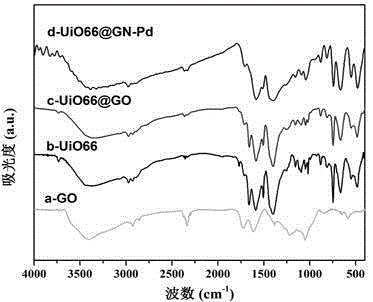

[0021] (2) Preparation method of metal organic fram...

Embodiment 2

[0025] (1) The preparation method of graphene oxide is the same as in Example 1;

[0026] (2) Preparation method of metal organic framework / graphene supported palladium nano composite catalyst:

[0027] Weigh 100mg of the graphene oxide prepared above and put it into a beaker, add 10mL DMF, ultrasonically disperse for 60min, and add 1.0g ZrCl to it in turn 4 , 712mg terephthalic acid and 200mL DMF, the resulting solution was slowly stirred at 120°C for 18h, allowed to stand, filtered, and the filter cake was washed with DMF. The crude product was immersed in dichloromethane for 12h, filtered with suction, and dried overnight at room temperature under vacuum. In an oven at 100°C and a constant temperature for 12 hours, the composite UiO66GO is finally obtained.

[0028] Disperse 200mg UiO66GO composite material in n-hexane and ultrasonic for 30min to form a quasi-homogeneous system. While stirring, add 2mL dropwise to a concentration of 0.04mol / LH 2 PdCl 4 The solution, continue to s...

Embodiment 3

[0030] (1) The preparation method of graphene oxide is the same as in Example 1;

[0031] (2) Preparation method of metal organic framework / graphene supported palladium nano composite catalyst:

[0032] Weigh 100mg of the graphene oxide prepared above and put it into a beaker, add 10mL DMF, ultrasonically disperse for 100min, and add 2.5g ZrCl to it in turn 4 , 1.8g terephthalic acid and 500mL DMF, the resulting solution was slowly stirred at 120°C for 24h, allowed to stand, filtered, and the filter cake was washed with DMF. The crude product was immersed in dichloromethane for 24h, filtered with suction, and dried at room temperature under vacuum overnight. In an oven at 120°C and a constant temperature for 24 hours, the composite material UiO66GO is finally obtained.

[0033] Disperse 200mg UiO66GO composite material in n-hexane and ultrasonic for 30min to form a quasi-homogeneous system. Under stirring, add 0.8mL dropwise to a concentration of 0.04mol / LH 2 PdCl 4 Solution, contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com