Water-based automotive paint, preparation method and application method thereof

A water-based, baking paint technology, applied in the direction of polyester paint, coating, etc., can solve the problems of insufficient gloss of bright solid color paint, high cost of water-based baking paint, unstable gloss, etc., and achieve simple anti-virus health measures and simple fire safety measures , Excellent effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

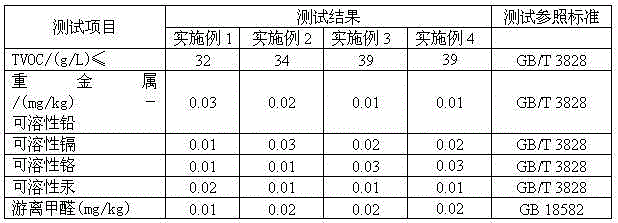

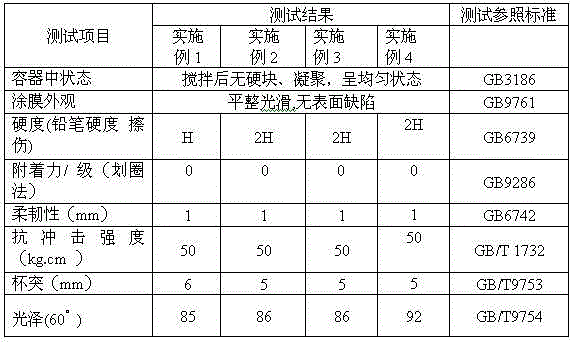

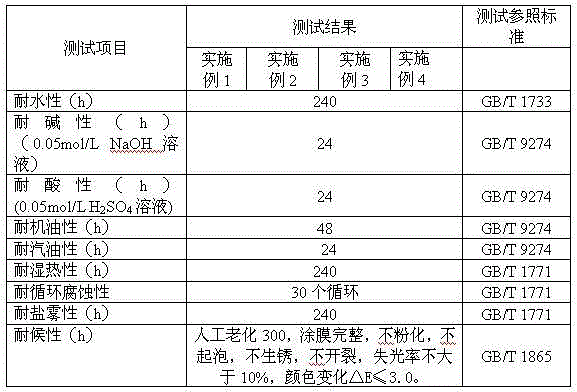

Examples

Embodiment 1

[0048] The preparation method of water-based automotive paint is as follows:

[0049] (1) Mix 100kg of water-based castor oil modified alkyd resin, 400kg of water-based acrylic resin, 2kg of modified polysiloxane emulsion of model W810, and 5kg of high molecular weight block containing affinity pigment groups of model W719 The copolymer, 1kg of W416 low molecular weight unsaturated polycarboxylic acid polymer and 20kg of deionized water were sequentially added into the stirring tank, and stirred for 10 minutes at a speed of 400r / min.

[0050] (2) Add 1 kg of AMP-95 2-amino-2-methyl-1-propanol, adjust the pH to 8, and stir for 10 minutes at 800 r / min.

[0051] (3) Add 337kg of water-based red paste, 10kg of fumed silica anti-sedimentation agent AS20, 30kg of propylene glycol methyl ether, 40kg of amino resin A, 10kg of amino resin B, and 1kg of heterocyclic ring RS01 The compound, 10kg of AR108 phosphate ester compound with polyester as the main chain, and 2kg of polyurethane th...

Embodiment 2

[0056] The preparation method of water-based automotive paint is as follows:

[0057] (1) Mix 200kg of water-based castor oil modified alkyd resin, 200kg of water-based acrylic resin, 8kg of modified polysiloxane emulsion of model W810, and 8kg of high molecular weight block containing affinity pigment groups of model W760 The copolymer, 3kg of low molecular weight unsaturated polycarboxylic acid polymer W416 and 26kg of deionized water were sequentially added into the stirring tank, and stirred for 15 minutes at a speed of 800r / min.

[0058] (2) Add 5kg of AMP-95 2-amino-2-methyl-1-propanol, adjust the pH to 9, and stir for 15 minutes at 400r / min.

[0059] (3) Add 300kg of water-based blue paste, 30kg of fumed silica anti-sedimentation agent AS20, 60kg of isopropanol, 60kg of amino resin A, 20kg of amino resin B, 2kg of RS01 miscellaneous Cyclic compound, 20kg AR108 phosphate ester compound with polyester as the main chain, 5kg PU40 polyurethane thickener, stir and disperse ...

Embodiment 3

[0064] The preparation method of water-based automotive paint is as follows:

[0065] (1) Mix 150kg of water-based castor oil modified alkyd resin, 352kg of water-based acrylic resin, 5kg of modified polysiloxane emulsion of model W810, and 6kg of high molecular weight block containing affinity pigment groups of model W760 The copolymer, 2kg of low molecular weight unsaturated polycarboxylic acid polymer W416 and 50kg of deionized water were sequentially added into the stirring tank, and stirred for 20 minutes at a speed of 600r / min.

[0066] (2) Add 3kg of AMP-95 2-amino-2-methyl-1-propanol, adjust the pH to 8, and stir for 12 minutes at 600r / min.

[0067] (3) Add 200kg of water-based white paste, 20kg of fumed silica anti-settling agent of AS20 type, 45kg of dipropylene glycol butyl ether, 80kg of amino resin A, 15kg of amino resin B, 2kg of RS01 miscellaneous Cyclic compound, 15kg AR108 phosphate ester compound with polyester as the main chain, 3kg PU40 polyurethane thicke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com