Production method of high-efficiency phosphorus-dissolving Aspergillus japonicus agent with tolerance to heavy metals

A technology of Aspergillus and heavy metals, applied in the field of environmental biology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Production of high-efficiency phosphorus-dissolving Aspergillus japonicus mold agent resistant to heavy metals

[0025] 1. Medium preparation:

[0026] 1) Strain preservation medium (solid, 1 L): 5 g of glucose, 18-20 g of agar, 40 g of leachate obtained by boiling and filtering potatoes, adding sweet potato starch wastewater to make up to 1 L, and natural pH;

[0027] 2) Strain activation medium (liquid, 1 L): 5 g of glucose, 40 g of leachate obtained by boiling and filtering potatoes, adding sweet potato starch wastewater to make up to 1 L, natural pH;

[0028] 3) Seed medium (liquid, 10 L): peptone 10 g, glucose 20 g, KH 2 PO 4 10 g, MgSO 4 ·7H 2 0.5 g, add sweet potato starch waste water and settle to 10 L, natural pH;

[0029] 4) Fermentation medium (liquid, 200 L): KH 2 PO 4 200 g, KH 2 PO 4 100 g, MgSO 4 ·7H 2 O 20 g, add sweet potato starch waste water to 200 L, natural pH;

[0030] All the above media were sterilized at 121°C for 15...

Embodiment 2

[0036] Embodiment 2: The growth-promoting effect of high-efficiency phosphorus-dissolving Aspergillus japonicus agent on Viburnum

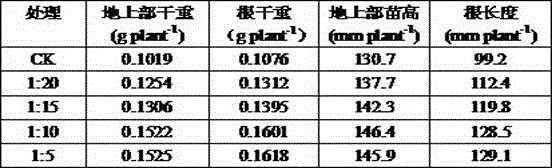

[0037] After mixing the prepared Aspergillus japonica agent with the soil at a ratio of 1:20, 1:15, 1:10, and 1:5, plant the germinated Viburnum seeds, and add untreated The chaff residue fermented by Aspergillus japonicus was used as the control. 5 pots were treated in each pot, and 3 seedlings were planted in each pot, which were placed in the greenhouse for unified management and watered regularly. After 60 days of planting and emergence of Viburnum, the growth conditions are shown in Table 1. It can be seen that the plants inoculated with Aspergillus japonicus inoculum, the dry weight of roots and seedlings of each addition ratio and the height of seedlings and root length all increase compared with the control group, and as the addition increases, the dry weight of roots and seedlings root length and seedling height showed an increasing tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com