Straight-through type fluoroplastic lined diaphragm valve

A straight-through, diaphragm valve technology, applied in the direction of diaphragm valve, diaphragm, valve details, etc., can solve the problems of normal production and operation, small flow rate of damming valve, medium retention and other problems, achieve excellent weather resistance, improve corrosion resistance, The effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

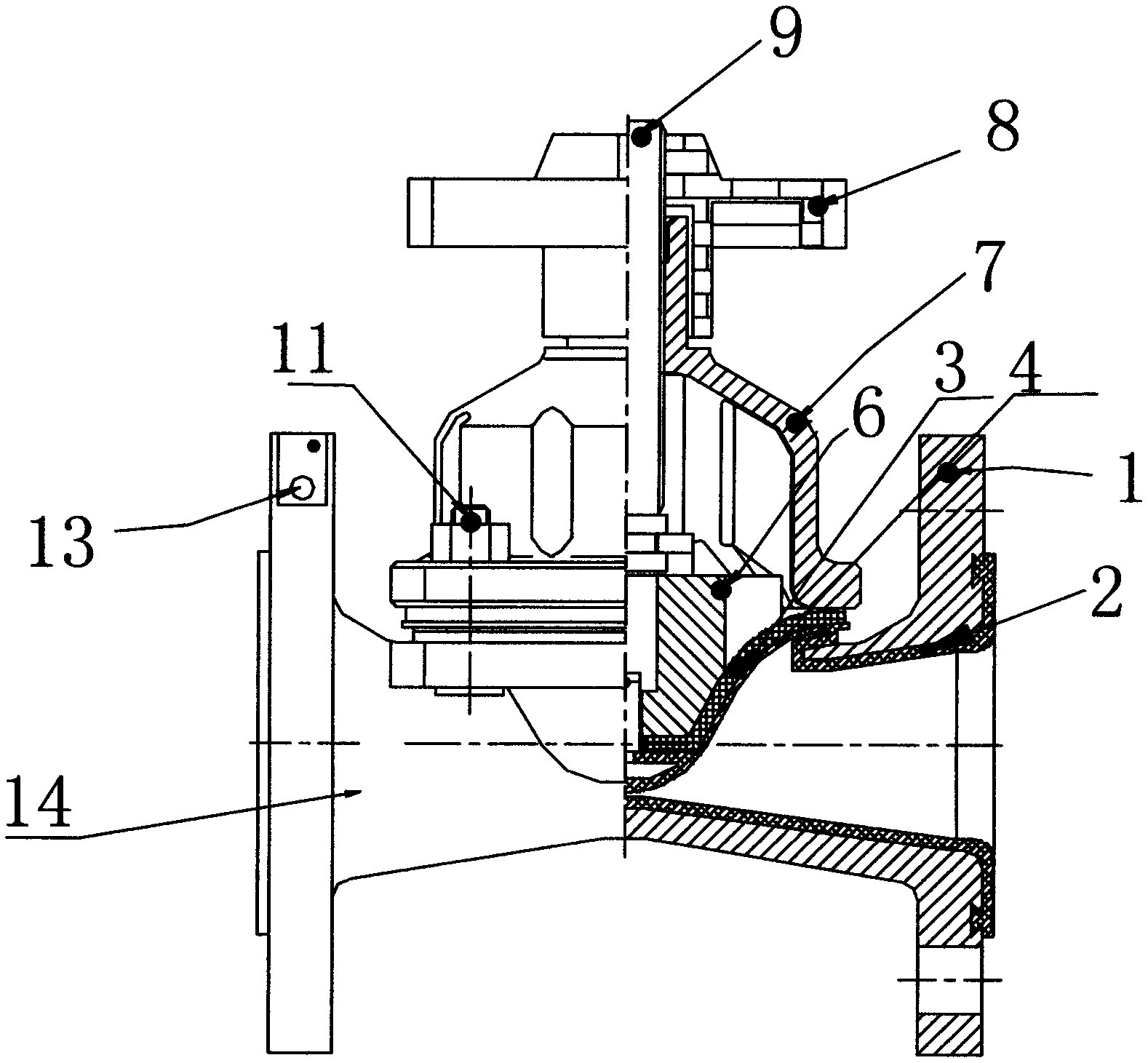

[0011] like figure 1 As shown, a straight-through fluorine-lined diaphragm valve includes a valve seat 1, a diaphragm 3, a diaphragm pad 4, a valve disc 6, a valve cover 7, and a hand wheel 8. The inner wall of the valve seat 1 is provided with a fluoroplastic lining layer 2, and the diaphragm The sheet 3 is made of fluoroplastic, and the valve flap 6 is provided with a pin opening. The diaphragm 3 and the diaphragm pad 4 are fixed on the valve flap 6 by the plug, and the valve cover 7, the valve flap 6, the diaphragm 3 and the diaphragm pad 4 are fixed on the on seat 1. The valve body 14 is also provided with a rivet 13 . The handwheel 8 is connected to the valve stem 9, the valve stem 9 can be directly connected with the pneumatic actuator or the electric actuator, the electric actuator is electrically connected with the controller, the controller is electrically connected with the remote control through the wireless network, and the wireless network can be Bluetooth , thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com