Electrolytic copper foil, method for producing electrolytic copper foil, and lithium ion secondary cell using electrolytic copper foil as collector

A technology for electrolytic copper foil and copper foil, which is applied in the field of non-aqueous electrolyte secondary batteries and can solve problems such as undisclosed technologies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

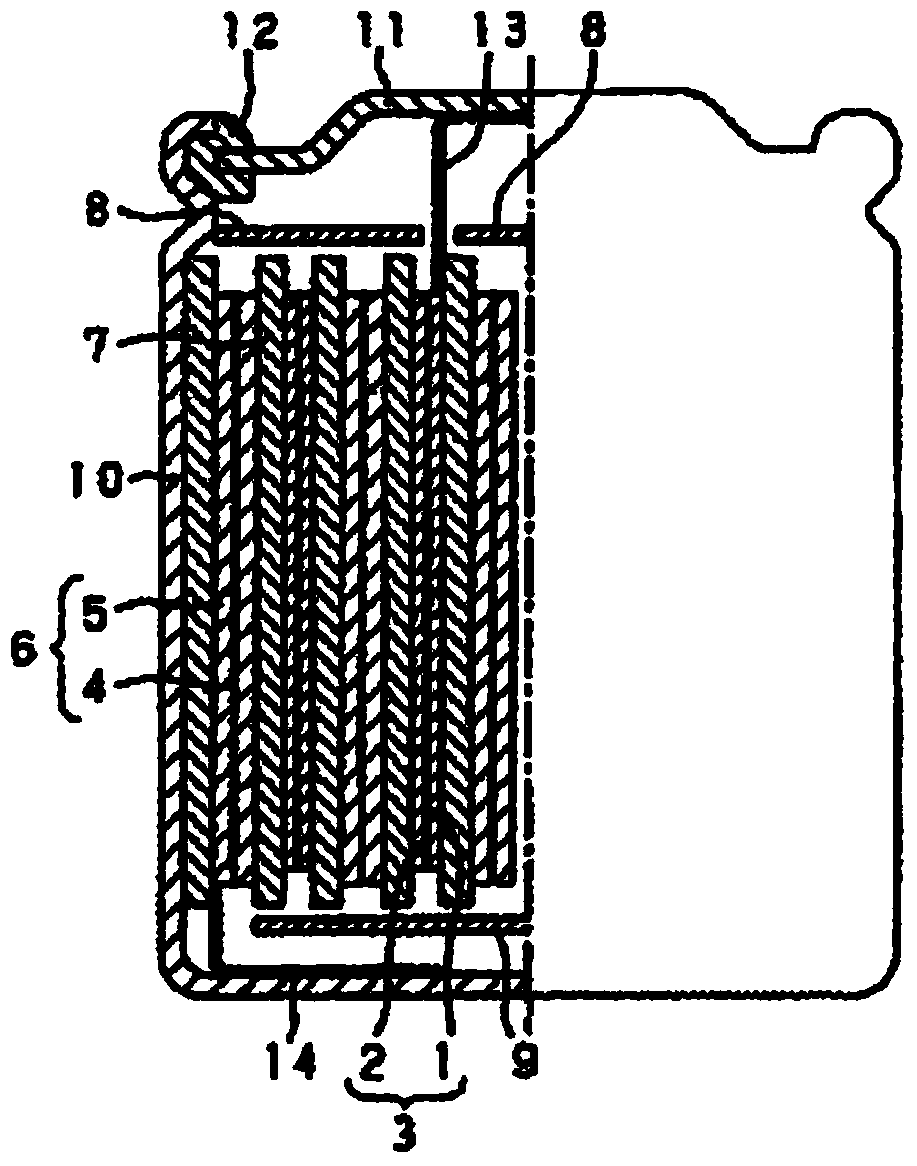

Image

Examples

Embodiment

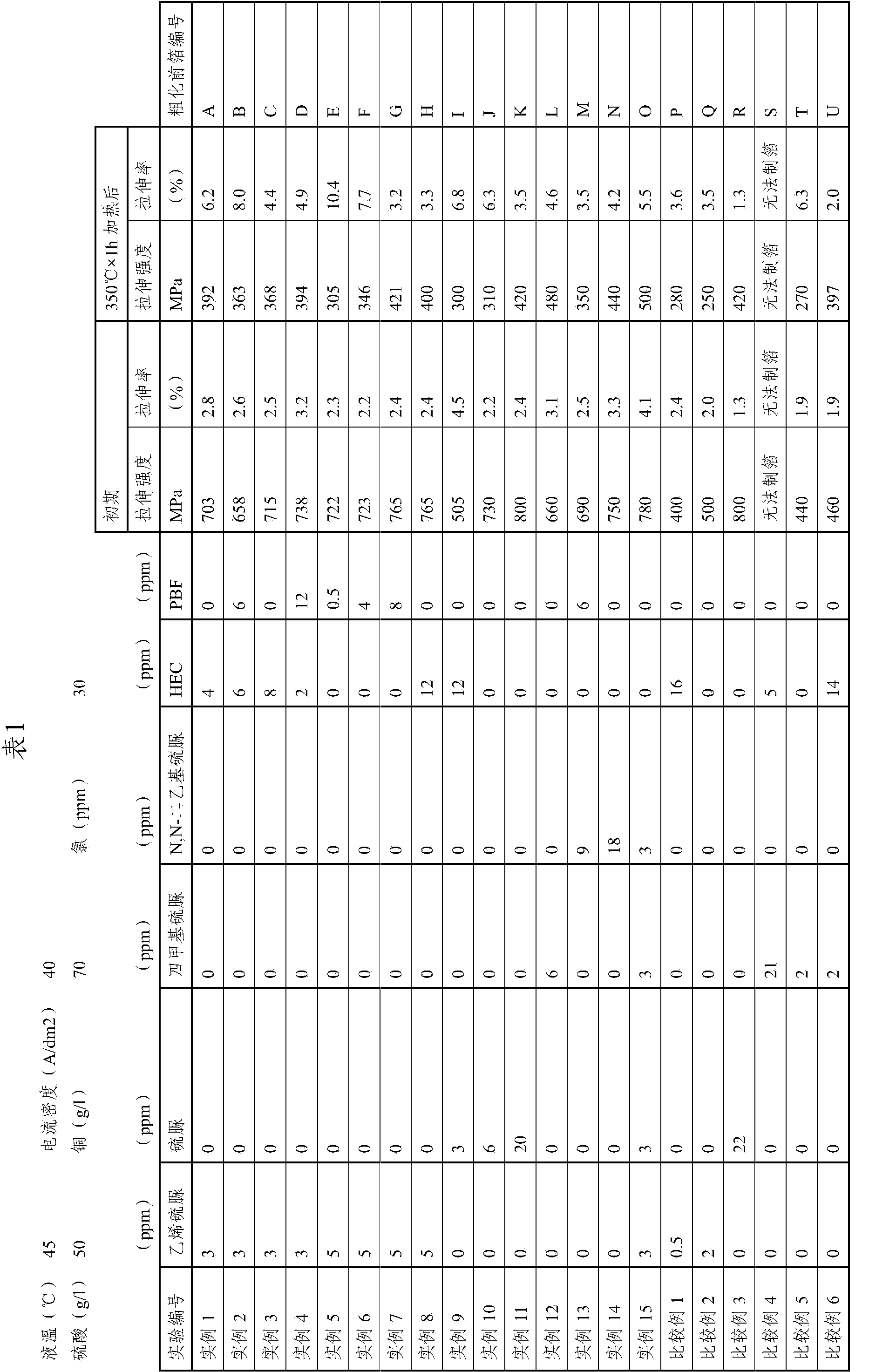

[0052] Hereinafter, the present invention will be described in detail based on examples.

example 1~15

[0053]

[0054] In the following copper sulfate electrolytic bath, add one or more compounds selected from compounds having a structure in which an SH group is bonded to an N heterocycle or thiourea compounds, and hydroxyethyl cellulose in the amount shown in Table 1 (HEC) or low molecular weight glue (PBF), after forming the electrolyte, place a titanium roller, and make an electrolytic copper foil film under the following electrolytic conditions.

[0055] Composition of copper sulfate electrolytic bath :

[0056] Copper (Cu) 70g / l

[0057] Sulfuric acid (H 2 SO 4 ) 50g / l

[0059] Electrolysis conditions :

[0060] Current density 40A / dm 2

[0061] Temperature 45°C

[0062]

[0063] Next, roughening plating was performed only on the S surface on the roll side. The roughening plating conditions are as follows. Coarse processing:

[0064] (A) Overfired electroplating for roughening treatment:

[0065] Copper 30g / dm 3 , and sulfu...

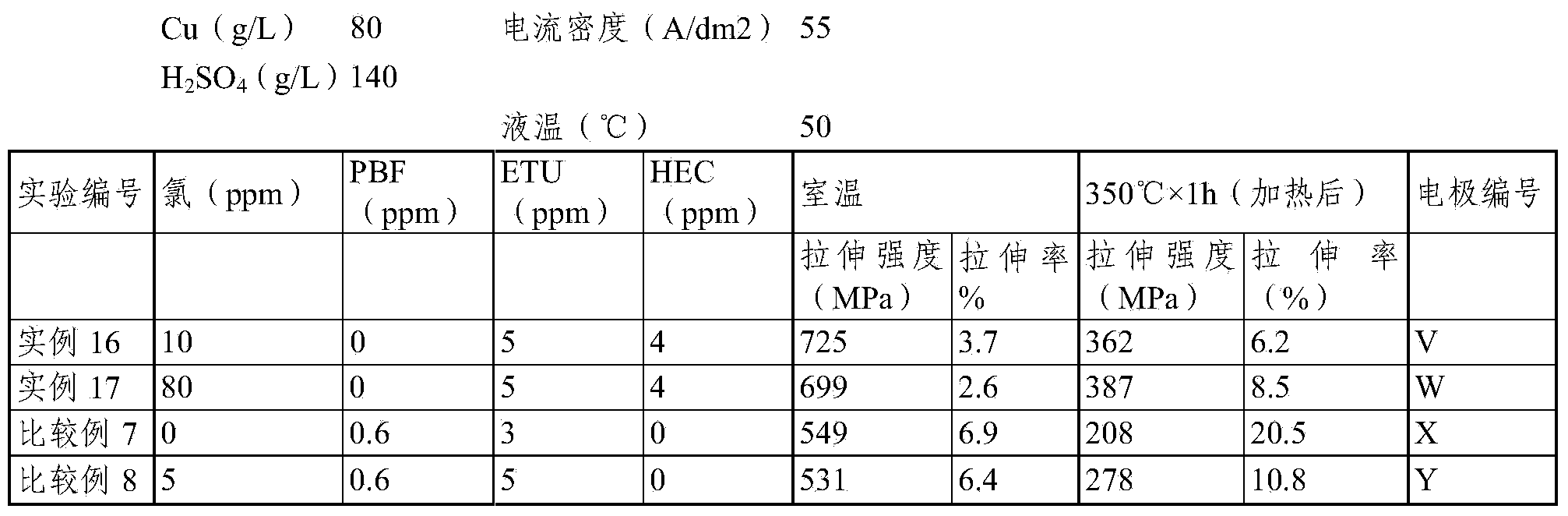

example 16、17

[0077]

[0078] According to the electrolyte composition and electrolysis conditions shown in Table 3, electrolytic copper foil was produced.

[0079] The untreated copper foil thus produced was subjected to the same surface treatment as in Example 1 above.

[0080] table 3

[0081]

[0082]Under the combined roughening conditions shown in Table 2 and Table 4, the smooth surface (S surface) of the electrolytic copper foil obtained in each example and comparative example was roughened, and the surface area of the roughened surface, Sm, was measured. As well as the surface roughness Rz, Ra, Ry, Sm of the rough surface, calculate the surface area ratio of the S surface and the M surface to the geometric surface. For example, use a laser microscope (manufactured by KEYENCE, VK-8700 / 9700) to observe the range of 50 μm × 50 μm (2500 μm2), and if the measurement result is 2500 μm 2 , the surface area ratio is set to be 1. The results and charge and discharge efficiencies ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com