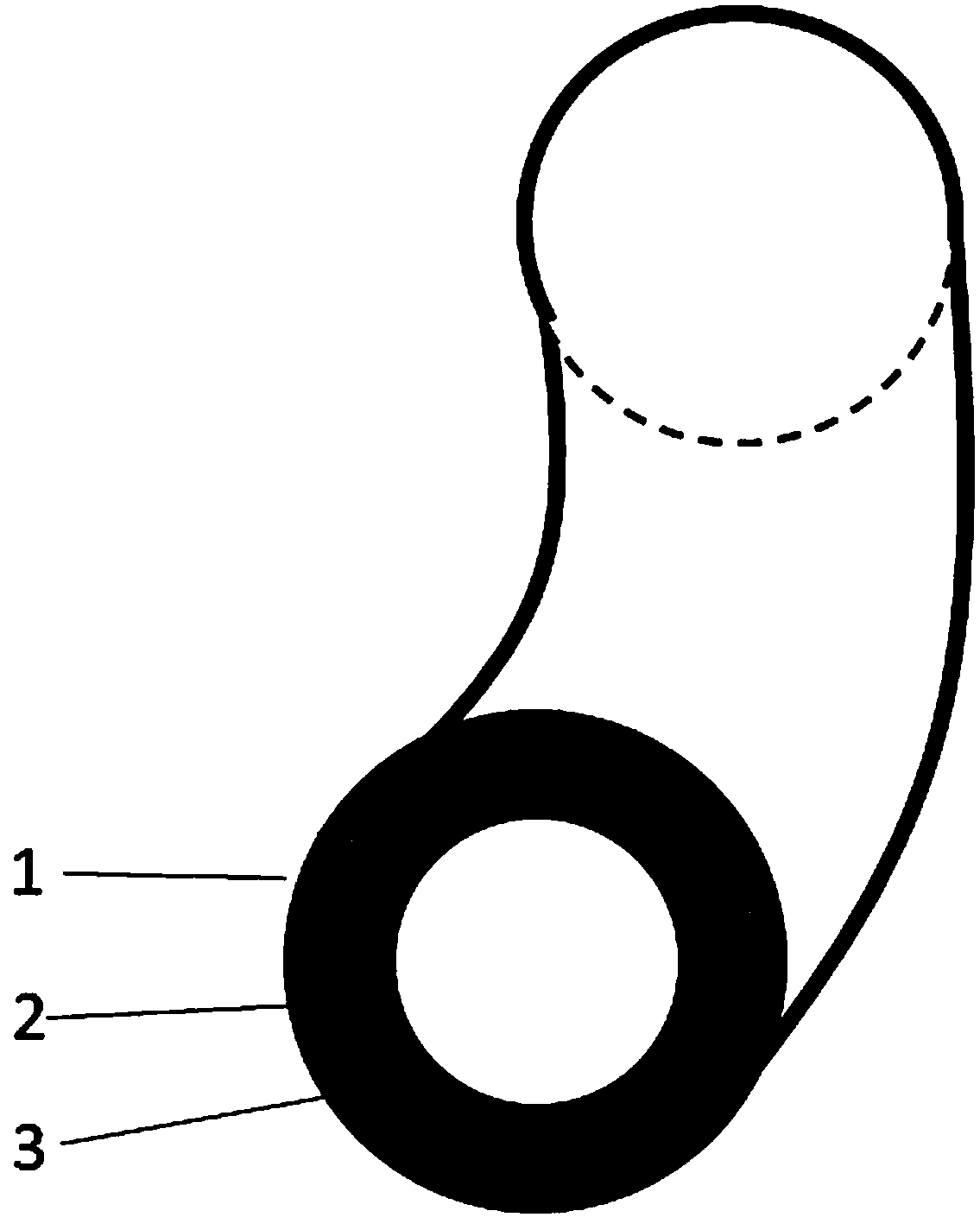

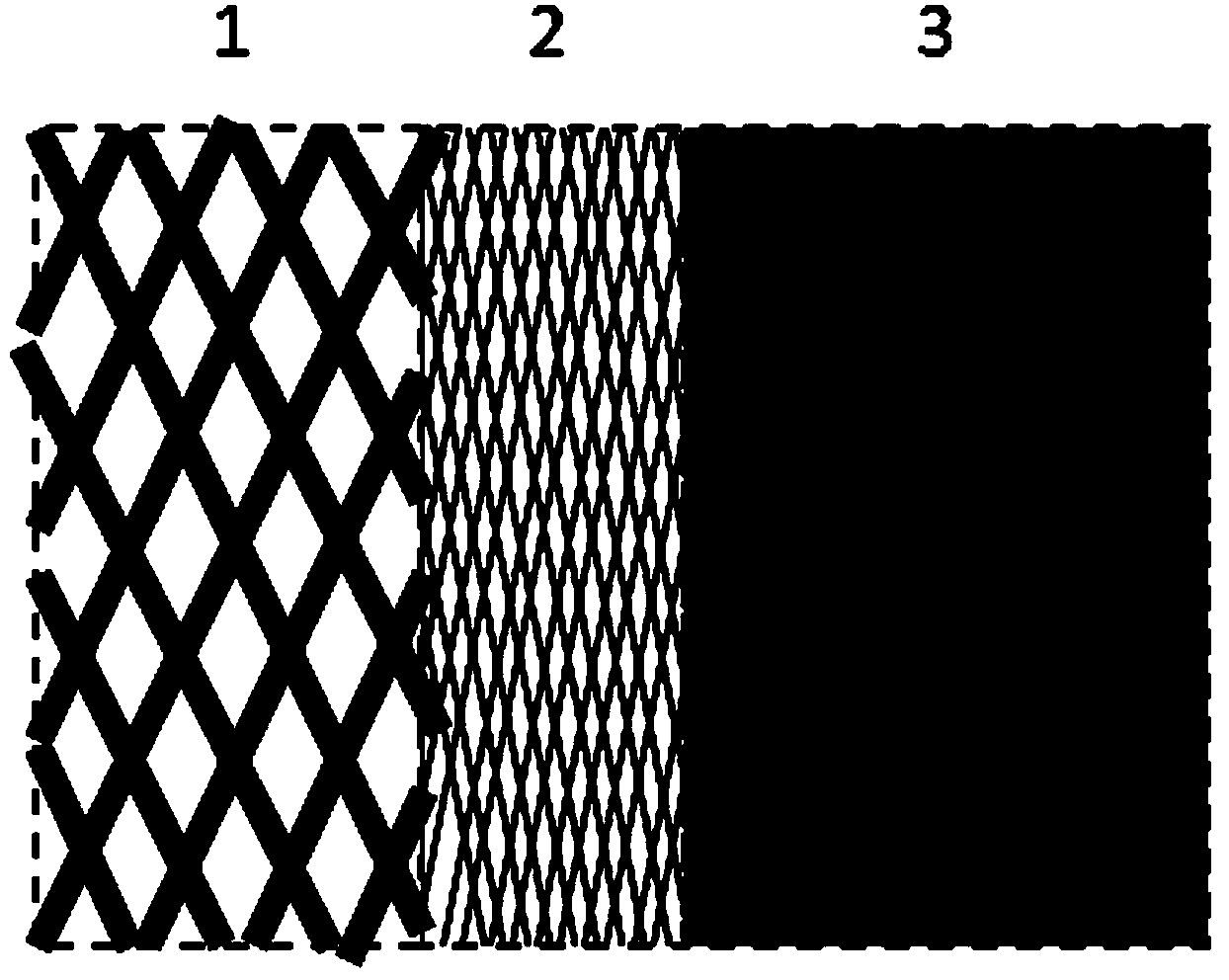

Neutral restoration catheter support of multilayer structure and manufacturing method of neutral restoration catheter support

A technology for nerve repair and catheter stent, applied in the field of biodegradable polymer nerve repair catheter stent and its preparation, can solve the problem of insufficient mechanical strength and cell growth space, electrospinning lack of mechanical strength, cell culture and implantation. Inconvenient operation and other problems, to achieve the effect of short preparation time, good biocompatibility, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

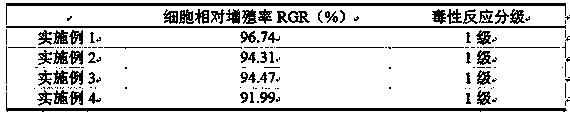

Examples

Embodiment 1

[0033] Proceed as follows:

[0034] (1) Weigh 3g of racemic polylactic acid and dissolve in 20ml of dichloromethane, heat and reflux for 1 hour to form solution A;

[0035] (2) Weigh 0.3g caprolactone lactate copolymer and dissolve it in 10ml of dichloromethane and N-dimethylamide (volume ratio: 7:3) mixed solvent, heat and reflux for 1 hour to form solution B ;

[0036] (3) Weigh 0.6g of L-polylactic acid and dissolve it in 10ml of mixed solvent of dichloromethane and N-dimethylamide (volume ratio: 7:3), heat and reflux for 1 hour to form solution C;

[0037] (4) Insert a stainless steel rod with a diameter of 3 mm into the above solution A, take it out vertically immediately after moderate stirring, place it upside down in a ventilated place, and volatilize at room temperature for more than 6 hours to obtain the inner tube;

[0038] (5) Set up the injection platform I, the syringe needle is a No. 5 flat-angle needle, and the distance between the needle tip and the receivin...

Embodiment 2

[0043] Proceed as follows:

[0044] (1) Weigh 2g of racemic polylactic acid and dissolve in 20ml of dichloromethane, heat and reflux for 1 hour to form solution A;

[0045] (2) Weigh 0.3g caprolactone lactate copolymer and dissolve it in 10ml of dichloromethane and N-dimethylamide (volume ratio: 7:3) mixed solvent, heat and reflux for 1 hour to form solution B ;

[0046] (3) Weigh 0.6g of L-polylactic acid and dissolve it in 10ml of mixed solvent of dichloromethane and N-dimethylamide (volume ratio: 7:3), heat and reflux for 1 hour to form solution C;

[0047] (4) Insert a stainless steel rod with a diameter of 3 mm into the above solution A, take it out vertically immediately after moderate stirring, place it upside down in a ventilated place, and volatilize at room temperature for more than 6 hours to obtain the inner tube;

[0048] (5) Set up the injection platform I, the syringe needle is a No. 5 flat-angle needle, and the distance between the needle tip and the receivin...

Embodiment 3

[0053] Proceed as follows:

[0054] (1) Weigh 3g of racemic polylactic acid and dissolve in 20ml of dichloromethane, heat and reflux for 1 hour to form solution A;

[0055] (2) Weigh 0.2g caprolactone lactate copolymer and dissolve it in 10ml of dichloromethane and N-dimethylamide (volume ratio: 7:3) mixed solvent, heat and reflux for 1 hour to form solution B ;

[0056] (3) Weigh 0.8g of L-polylactic acid and dissolve it in 10ml of mixed solvent of dichloromethane and N-dimethylamide (volume ratio: 7:3), heat and reflux for 1 hour to form solution C;

[0057] (4) Insert a stainless steel rod with a diameter of 2 mm into the above solution A, take it out vertically immediately after moderate stirring, place it upside down in a ventilated place, and volatilize at room temperature for more than 6 hours to obtain the inner tube;

[0058] (5) Set up the injection platform I, the syringe needle is a No. 5 flat-angle needle, and the distance between the needle tip and the receivin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com