Preparation method for effective components of buxus sinica varparvifolia and application of effective components

A technology of Buxus microphylla and active components, which is applied in the direction of medical preparations containing active ingredients, drug combinations, and pharmaceutical formulas, can solve the problems of unknown drug efficacy material basis for cardiovascular diseases, and achieve improved operability and improved The effect of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 100 g of Buxus microphylla was pulverized and extracted twice with 10 times the mass concentration of 75% ethanol aqueous solution under reflux, and the time of each extraction was 2 hours. The extracts were combined, filtered, and concentrated under reduced pressure until there was no alcohol smell, and 400 ml aqueous solution of Buxus microphylla was obtained. .

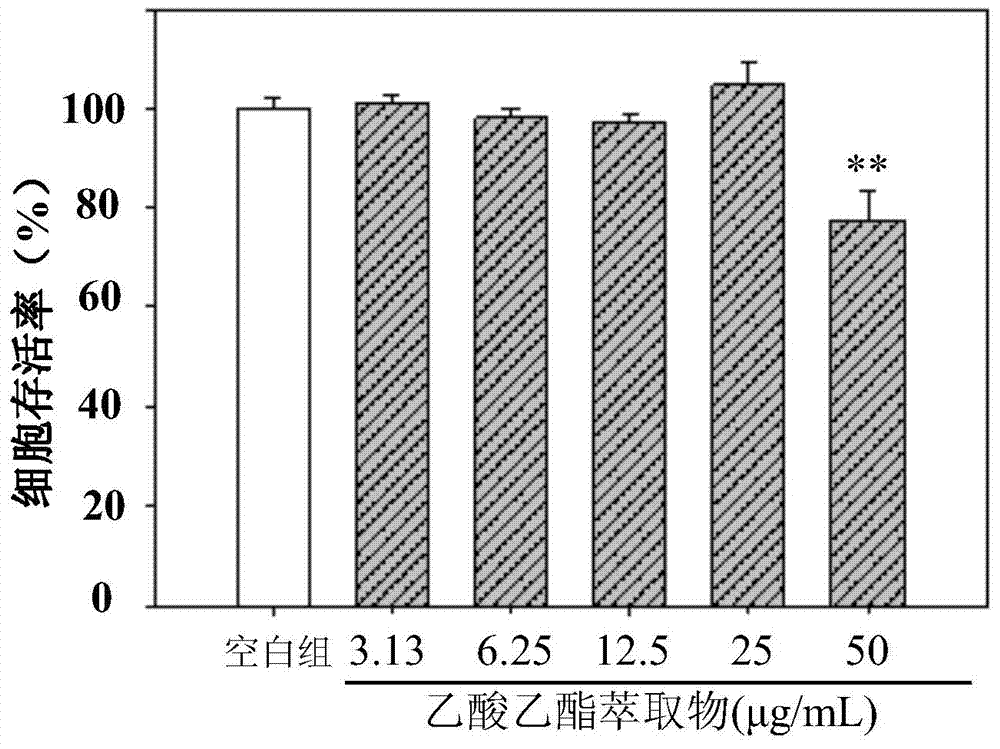

[0039] The aqueous solution of Euonymus microphylla was acidified with aqueous sulfuric acid until the pH value of the acidified solution was 3, extracted three times with 450 ml of ethyl acetate, combined with the ethyl acetate extracts, concentrated under reduced pressure to the extract to obtain the ethyl acetate extract;

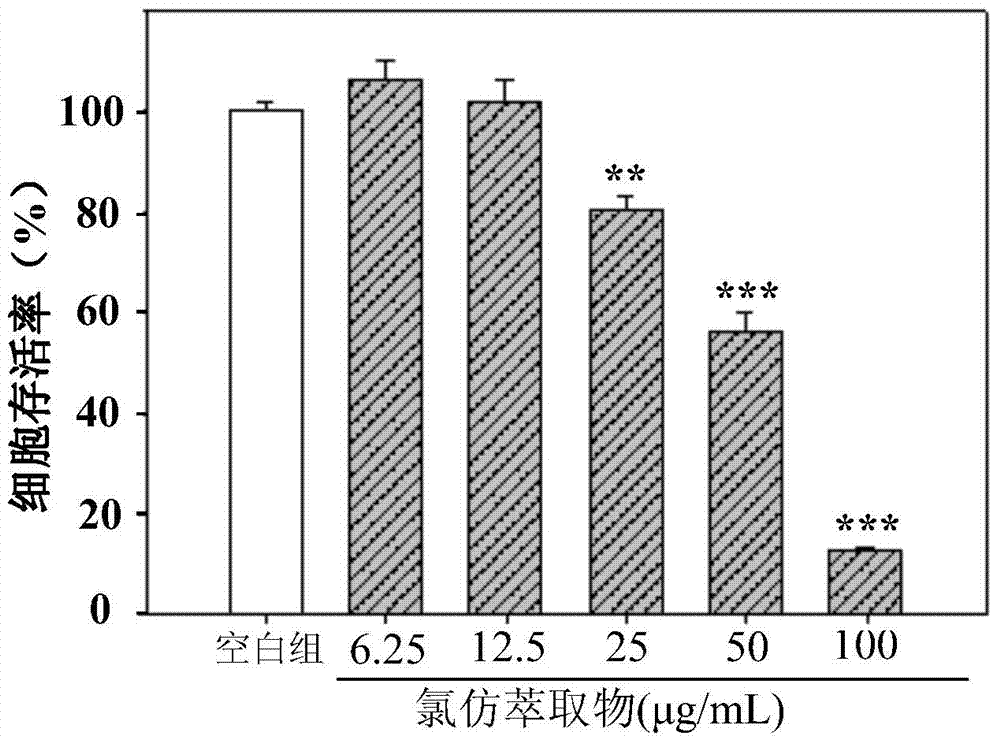

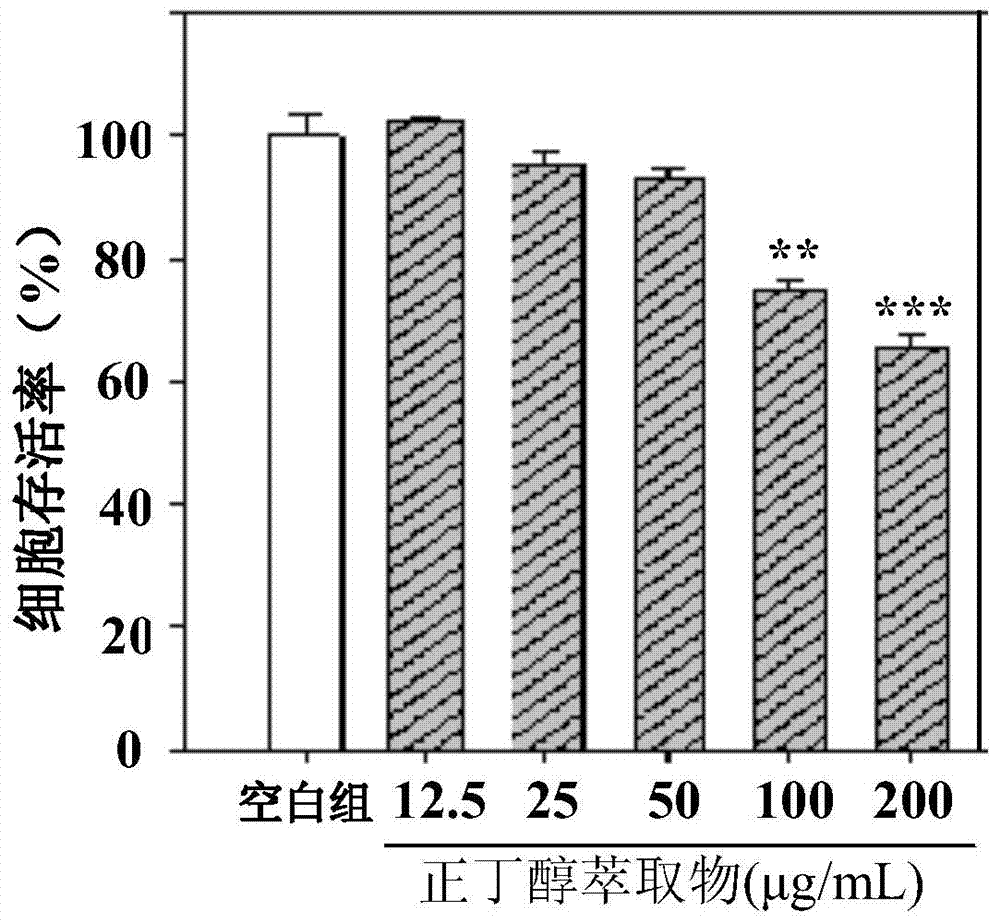

[0040] After ethyl acetate extraction, the water part was adjusted to pH 9 with sodium hydroxide solution, extracted three times with 450 ml of chloroform, the extracts were combined, concentrated under reduced pressure, and dried under normal pressure to obtain the chloroform extract, ...

Embodiment 2

[0044] After crushing 100g of Buxus microphylla, use 20 times the mass concentration of 95% ethanol aqueous solution to reflux and extract 4 times, each extraction time is 0.5 hours, combine the extracts, filter, concentrate under reduced pressure to recover the solvent, and obtain the extract of Buxus microphylla

[0045] Suspend the extract of Buxus microphylla with 150 mL of water, acidify the aqueous solution with aqueous hydrochloric acid until the pH of the acidified solution is 1, and extract once with 150 ml of ethyl acetate to obtain the water part after ethyl acetate extraction; The water part of the solution was adjusted to pH 14 with potassium hydroxide solution, extracted twice with 150 ml of chloroform, the extracts were combined, concentrated under reduced pressure, and dried under normal pressure to obtain the effective components of Buxus microphylla.

Embodiment 3

[0047]After crushing 100g of Euonymus microphylla, reflux extraction with 5 times the mass concentration of 50% ethanol aqueous solution for 3 times, each extraction time is 4 hours, combine the extracts, filter, concentrate under reduced pressure until there is no alcohol smell, and continue to concentrate to obtain 200 ml Buxus microphylla aqueous solution.

[0048] The aqueous solution of Euonymus microphylla is acidified with formic acid aqueous solution until the pH value of the acidified solution is 6, and extracted 5 times with 200 ml of ethyl acetate to obtain the water part after ethyl acetate extraction; the water part after ethyl acetate extraction is treated with calcium hydroxide The solution was adjusted to a pH value of 8, extracted four times with 200 ml of chloroform, the extracts were combined, concentrated under reduced pressure, and dried under normal pressure to obtain the effective components of Euonymus microphylla.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com