Cylinder rapid forming tool

A forming tool and fast technology, applied in the direction of lathe tools, manufacturing tools, tool holder accessories, etc., can solve the problems of difficult to guarantee product quality, lengthen axial length, high production cost, etc., to achieve good product quality, production The effect of low cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

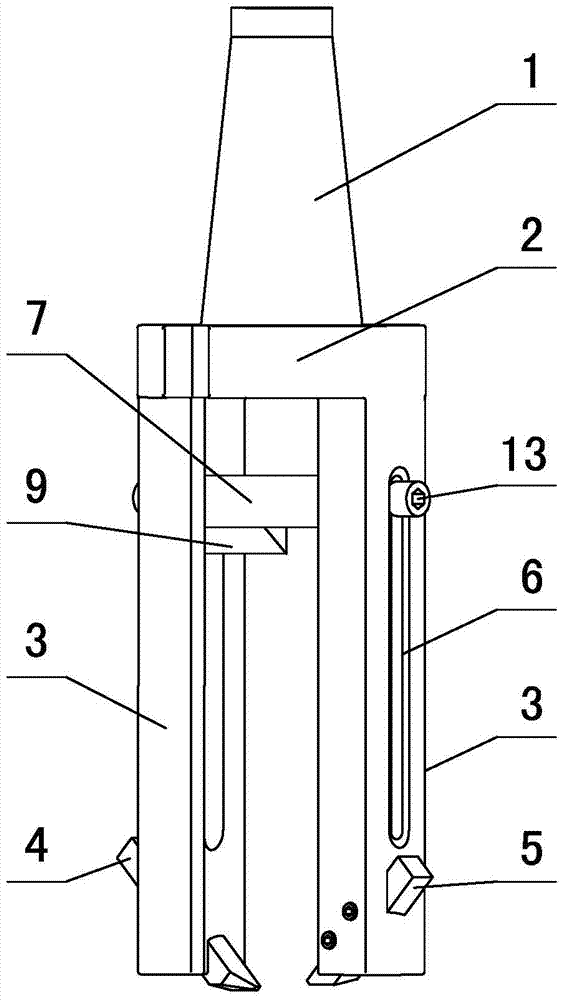

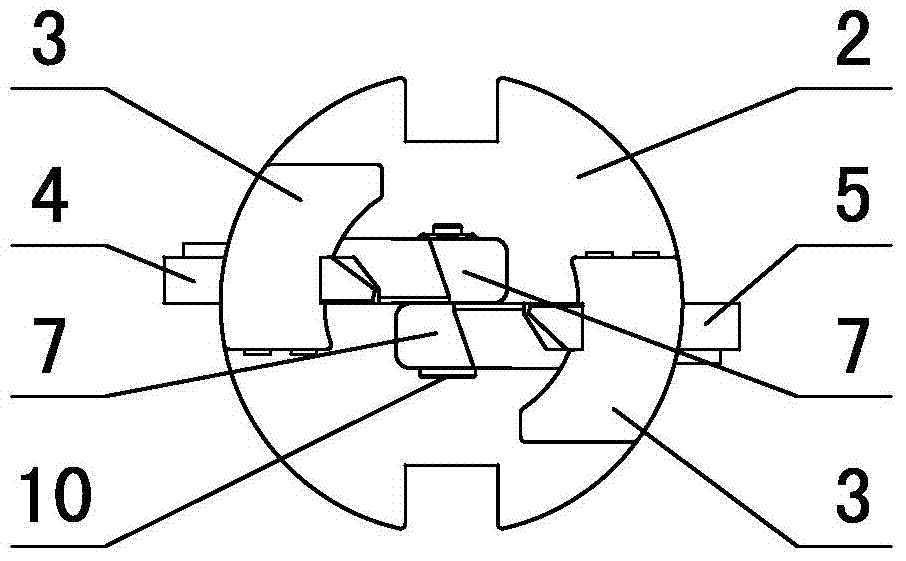

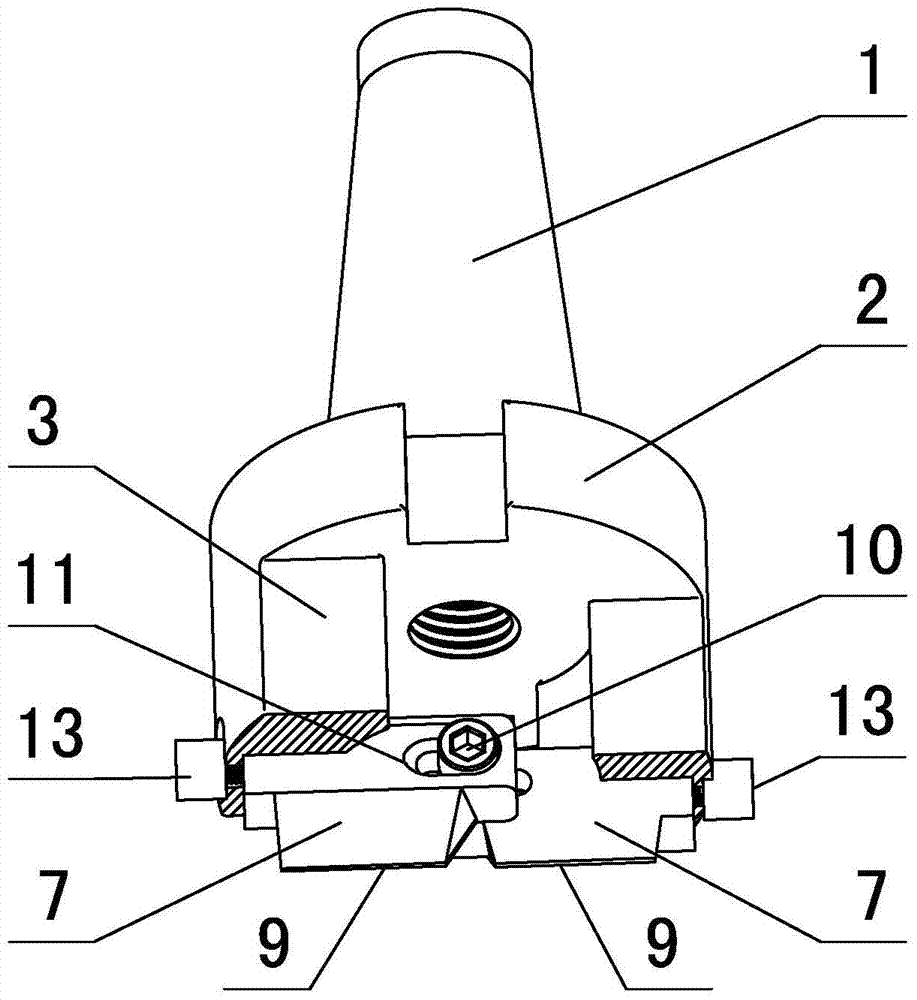

[0029] in such as figure 1 In the shown embodiment 1, a cylindrical forming combination cutter includes a knife handle located on the centerline of tool rotation, the lower end of the knife handle 1 is provided with a tool holder disc 2, and the axial direction of the outer edge of the tool holder disc is upward There are several tool racks for fixing processing tools. The tool racks include a pair of cutting racks 3 arranged on both sides of the tool rotation centerline. The ends of the cutting racks away from the tool holder disc are respectively provided with cutter heads pointing to the tool rotation center. The outer circle cutting knife in the line direction, the said outer circle cutting knife comprises the outer circle rough cutting knife 4 and the outer circle fine cutting knife 5, and the outer circle rough cutting knife and the outer circle fine cutting knife are respectively arranged on the two sides of the tool rotation center line On the cutting frame, the outer ...

Embodiment 2

[0031] The cross-section of the cutting frame in Example 2 is fan-shaped, and the cross-section of the cutting frame is fan-shaped. The cutting frames on both sides are symmetrically arranged with the center line of the tool rotation as the axis. The surface is on the same central plane of the tool, and the outer circular cutting knife is inclined on the cutting frame. set screw. The angle between the outer circle cutting knife and the cutting frame is 45 degrees, the cross section of the handle of the outer circle cutting knife is rectangular, and the side of the knife handle of the outer circle fine cutting knife near the tool holder disc is provided with a sawtooth structure 14, and the cutting frame There is a corresponding sawtooth structure on the joint surface with the tool handle. The tooth tip angle of the sawtooth structure is 90 degrees, and the length of the slope on both sides of the tooth tip is 0.5 mm. The distance is greater than the length of cutting frame, a...

Embodiment 3

[0033] A pair of rolling frames 15 (see Figure 8 ), the end of the rolling frame far away from the knife holder disc is provided with a rolling device 16 protruding toward the direction of the tool rotation centerline (see Figure 5 ), the distance between the rolling device and the turret disc is smaller than the distance between the cutter head of the outer round fine cutting knife and the turret disc. The rolling device includes a cylindrical ball fixing sleeve 17 arranged vertically with the rolling frame. The ball fixing sleeve is provided with an external thread, and the ball fixing sleeve is screwed with the rolling frame through the external thread. There is an opening, the steel ball 18, the steel bowl 19 and the compression spring 20 are arranged in sequence in the ball fixing sleeve, and one end of the compression spring is connected to the adjusting screw 21, the diameter of the opening end of the ball fixing sleeve is smaller than the diameter of the steel ball, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com