Crystal silicon surface femtosecond laser selective ablation method based on electron dynamic control

An electronic dynamic control, femtosecond laser technology, applied in the field of femtosecond laser applications, can solve the problem of not considering material properties, and achieve the effect of improving processing accuracy and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further introduced below in conjunction with the accompanying drawings and embodiments.

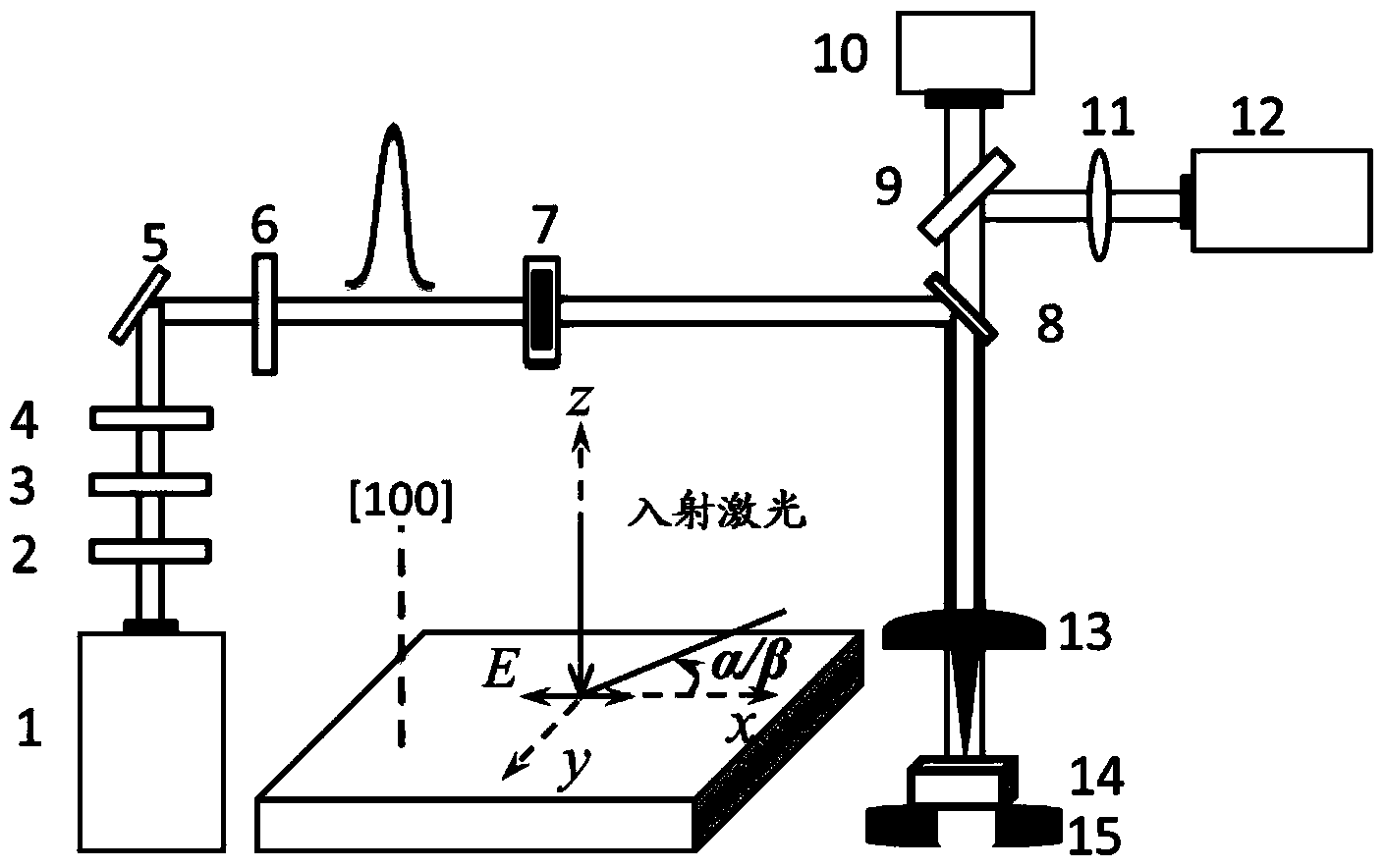

[0024] In this embodiment, the processing method of controlling the femtosecond laser-induced selective ablation of periodic corrugated micro-nano structures on the surface of crystal silicon, the specific processing optical path is as follows figure 1 shown. The processing optical path is that the femtosecond laser 1 generates femtosecond laser pulses. After the femtosecond laser pulses pass through the first half-wave plate 2, the polarizer 3, and the second half-wave plate 4, they are reflected by the first mirror 5 and pass through a quarter A wave plate 6 and a mechanical switch 7 are reflected by the second reflector 8 and focus on the surface of the sample 14 after being reflected by the achromatic double-glued plano-convex lens 13. The sample 14 to be processed is fixed on the six-dimensional mobile platform 15; the white light source 10 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com